Production process of concave surface packaging box

A production process and packaging box technology, applied in the production process field of concave packaging boxes, can solve the problems of product damage, glue hardening, glue easily falling off, etc., to achieve a stable bonding position, prevent yellowing and hardening, and not easy shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

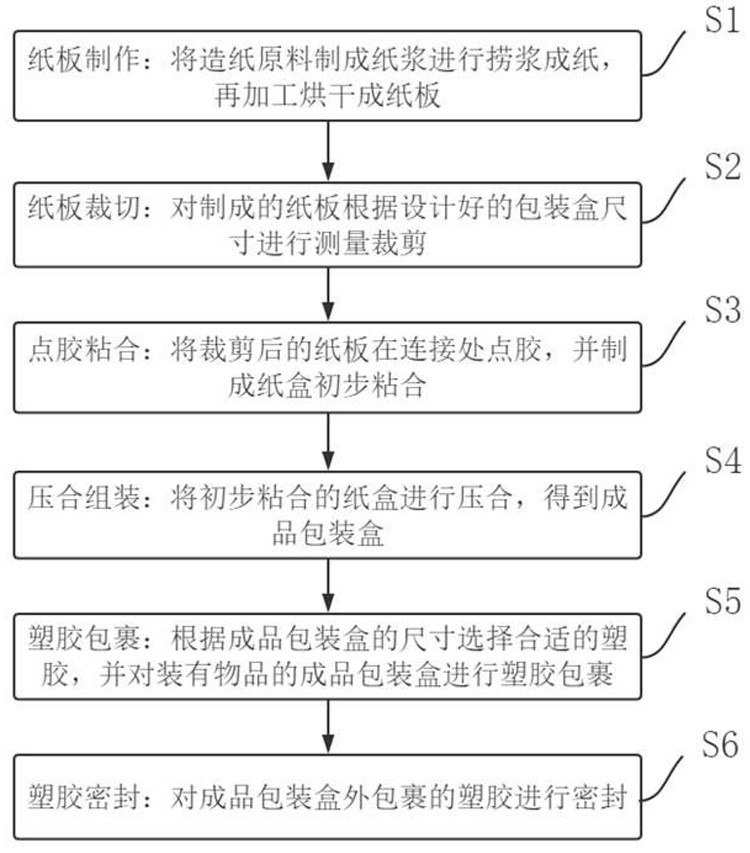

[0023] see figure 1 , the present invention provides a technical solution: a production process of a concave packaging box, comprising the following steps:

[0024] Step 1. Cardboard production: make paper pulp from papermaking raw materials, extract the pulp into paper, and then process and dry it into cardboard.

[0025] Step 2, cardboard cutting: measure and cut the finished cardboard according to the designed packaging box size.

[0026] Step 3. Glue dispensing and bonding: Dispensing glue on the joints of the cut cardboard, and making a carton for preliminary bonding.

[0027] Step 4: Pressing and assembling: press the preliminarily bonded cartons to obtain the finished packaging box.

[0028] Step 5, plastic wrapping: choose the appropriate plastic according to the size of the finished product packaging box, and plastic wrap the finished product packaging box containing the items.

[0029] Step 6. Plastic sealing: seal the plastic wrapped outside the finished product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com