Double-layer furnace burden radial equal thickness burden distribution machine for rotary hearth furnace and design method of burden distribution curve of double-layer furnace burden radial equal thickness burden distribution machine for rotary hearth furnace

A technology of rotary hearth furnace and double-layer furnace, which is applied in the direction of furnace, furnace type, fluidized bed furnace, etc. It can solve the problems of crushing, screw discharge trouble, large drop, etc., and achieve the effect of important engineering practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

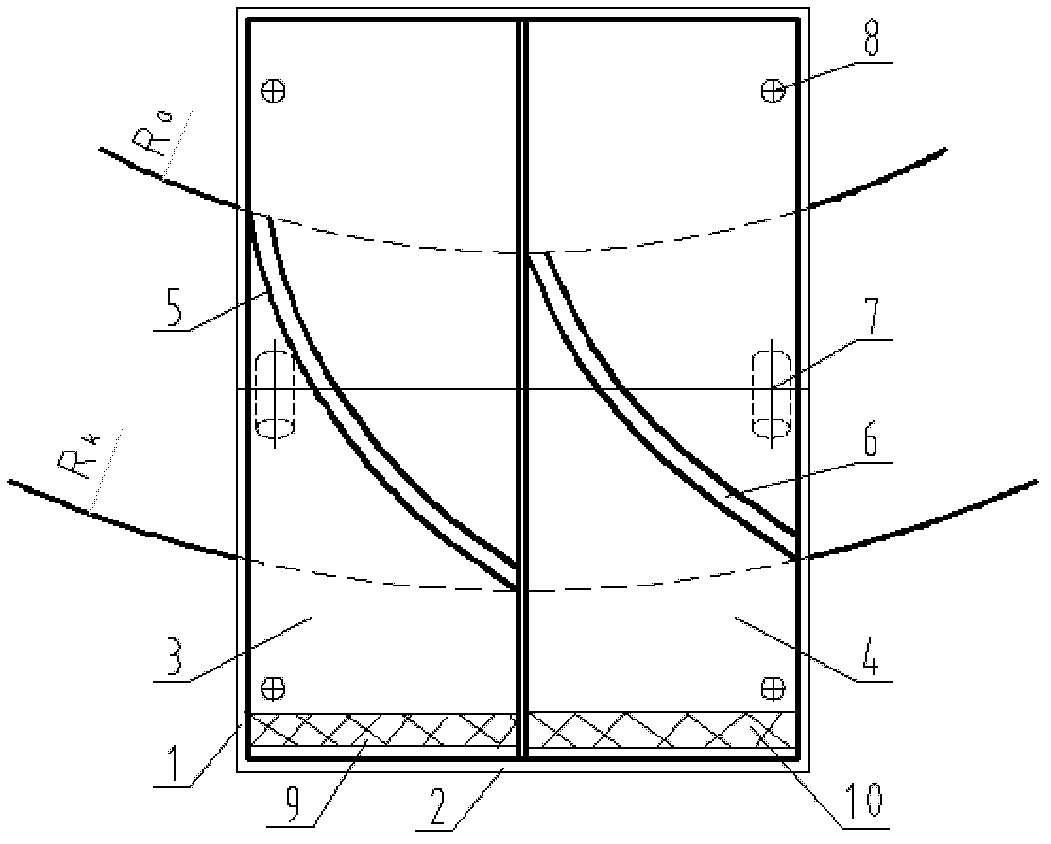

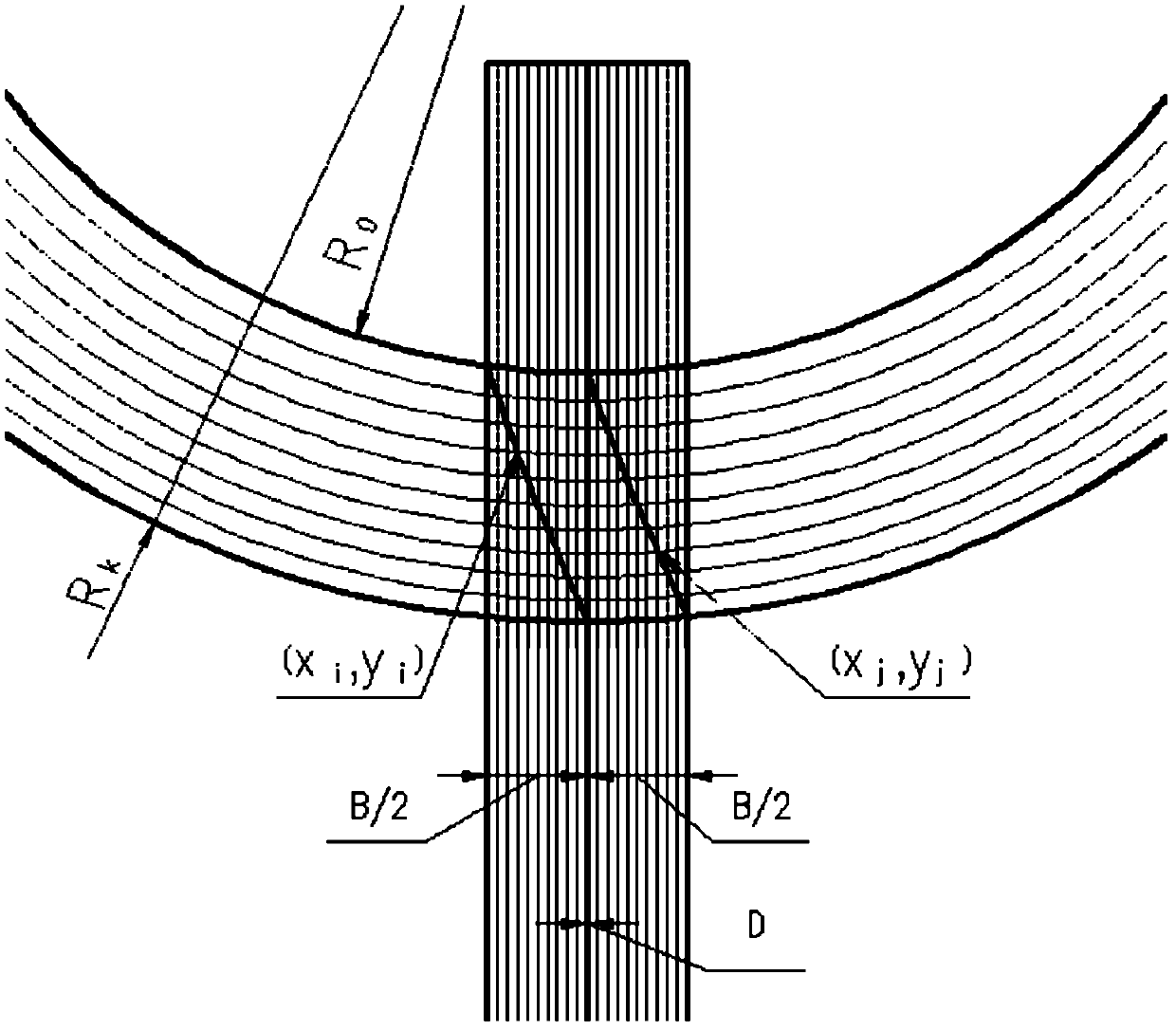

[0031] Such as figure 1 Shown is a schematic structural view of the double-layer burden radial equal-thickness distribution machine of the present invention. The present invention double-layer charging material radial equal thickness distributing machine, comprises hopper 1 and vibrating motor 7 installed on both sides of hopper 1, wherein, the 4 corners of the bottom of hopper 1 are all provided with springs for supporting and damping 8; A partition plate 2 is arranged in the material trough 1, and the material trough 1 is divided into a furnace material trough 3 and a bottom material trough 4 for conveying the bottom material with the same volume and size. , The bottom surface of the bottom trough 4 is provided with a bottom material cutting incision 6; at the entrance of the trough 1, a left sieve plate 9 and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com