Method for producing hot rolled ribbed bars by controlling austenite strain accumulation after finished rolling

A technology of hot-rolled ribbed steel bars and production methods, which is applied in the production field of high-strength energy-saving construction steel products, and can solve the problem of giving specific indicators for the grain size of ribbed steel bars, not specifying the refinement, and having no final rolling pass strain Accumulation and other issues to achieve the effect of expanding market sales, improving plasticity and welding performance, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

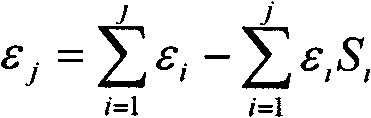

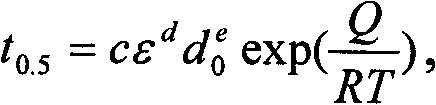

[0024] Taking the VN microalloyed ribbed steel bar with a diameter of 16 mm as an example, the chemical composition analysis (mass fraction) of the steel bar is shown in Table 1 ①. After smelting, a continuous casting slab of 150mm×150mm is obtained. Put the continuous casting slab into a walking heating furnace, heat it at 800°C-1200°C for 1.2 hours, and start rolling at 1150°C. After 16 passes of rolling, a ribbed steel bar with a diameter of 16 mm is obtained. The deformation temperature and strain of the last 7 passes (10-16 passes) are designed to ensure the accumulated strain of austenite. After the computer-aided design model, the designed 7-pass rolling process is:

[0025] pass

[0026] Design the final rolling pass, that is, the deformation temperature of the 16th pass is 1190°C, the strain rate is 39 / s, and the corresponding critical strain of austenite dynamic recrystallization is 0.532, which is 95% of the critical strain. The cumulative strain of the...

Embodiment 2

[0028] Taking the VN microalloyed ribbed steel bar with a diameter of 25 mm as an example, the chemical composition analysis of the steel bar is shown in Table 1 ②. After smelting, a continuous casting slab of 150mm×150mm is obtained. Put the continuous casting slab into a walking heating furnace, heat it at 800°C-1200°C for 1.2 hours, and start rolling at 1050°C. After 16 passes of rolling, a ribbed steel bar with a diameter of 16 mm is obtained. The deformation temperature and strain of the last 7 passes (10-16 passes) are designed to ensure the accumulated strain of austenite. After the computer-aided design model, the designed 7-pass rolling process is:

[0029] pass

10

11

12

13

14

15

16

critical strain

0.577

0.627

0.640

0.649

0.622

0.631

0.704

Strain accumulation

0.113

0.490

0.630

0.505

0.237

0.427

0.692

dynamic recr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com