Multi-magnetic field magnetron sputtering cathode

A magnetron sputtering, multi-magnetic field technology, applied in the field of magnetron sputtering cathodes with multi-magnetic field distribution, can solve the problem of small uniform magnetic field range, limiting the effective sputtering length and sputtering time of single rectangular cathode magnetron sputtering coating, Target bombardment area concentration and other problems, to achieve the effect of wide application, increase the effective coating distance and coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing

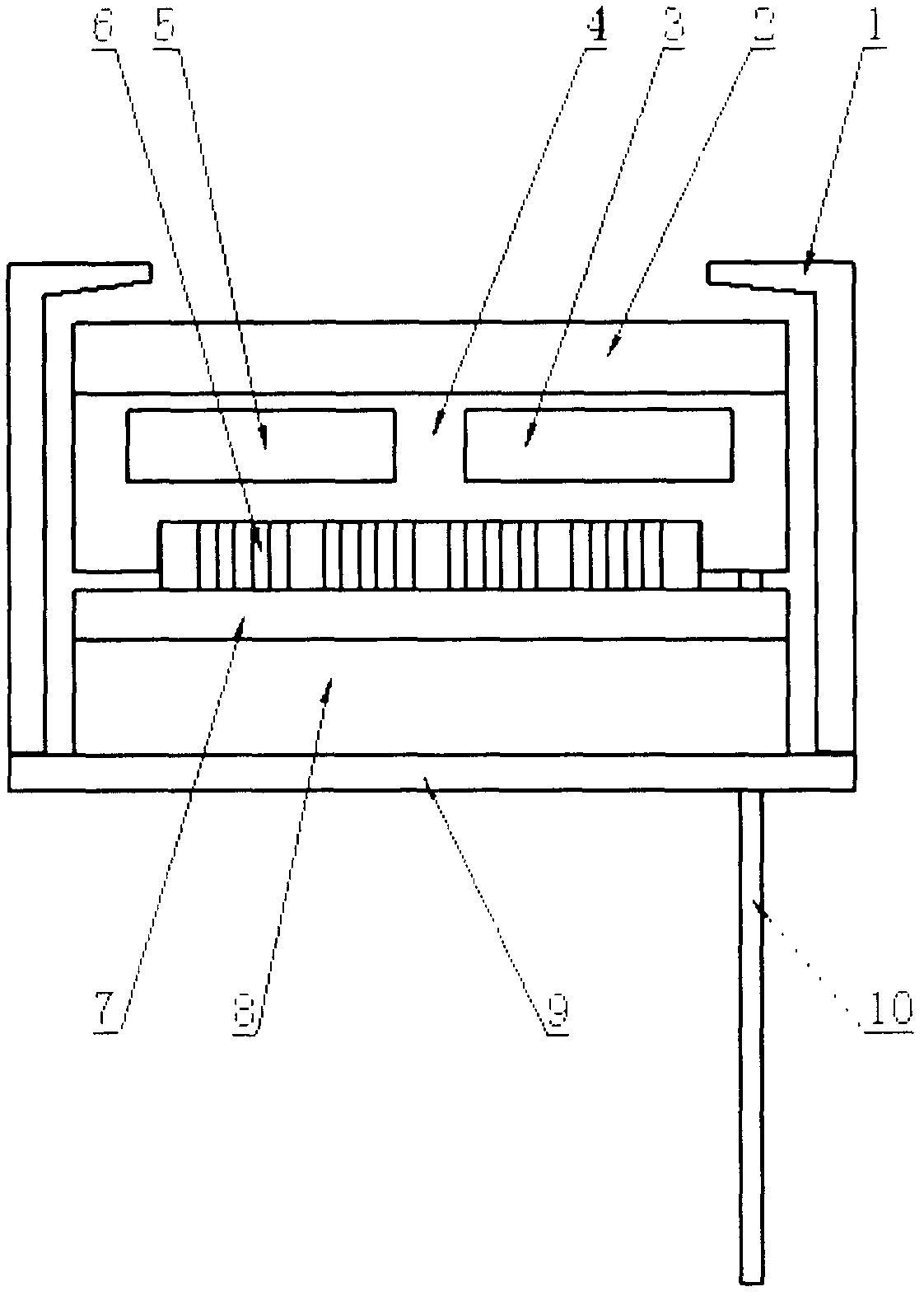

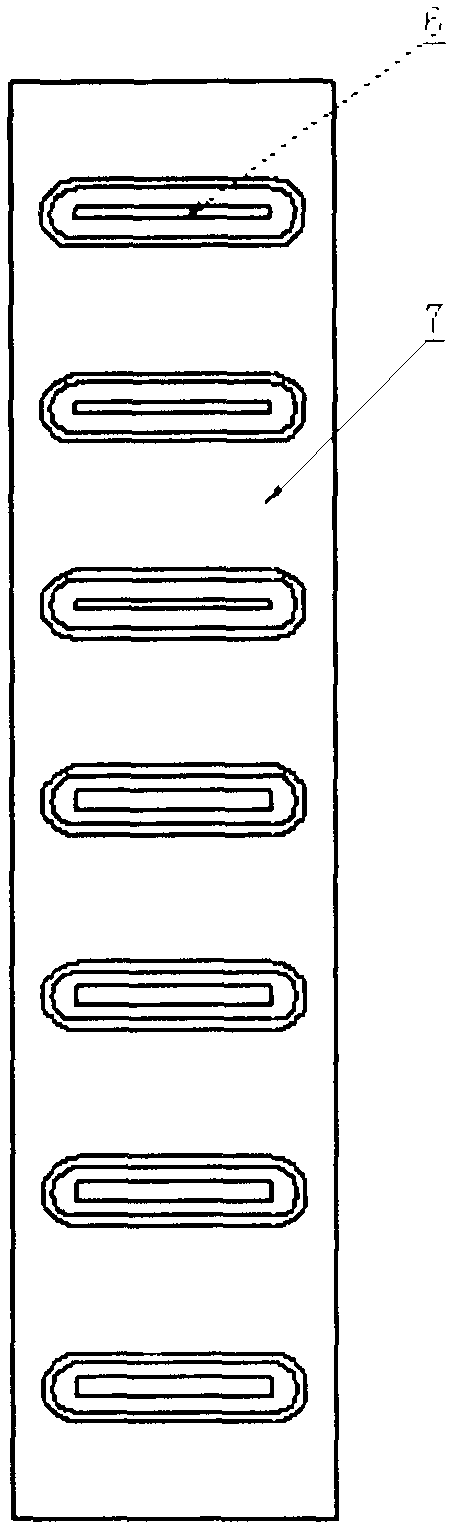

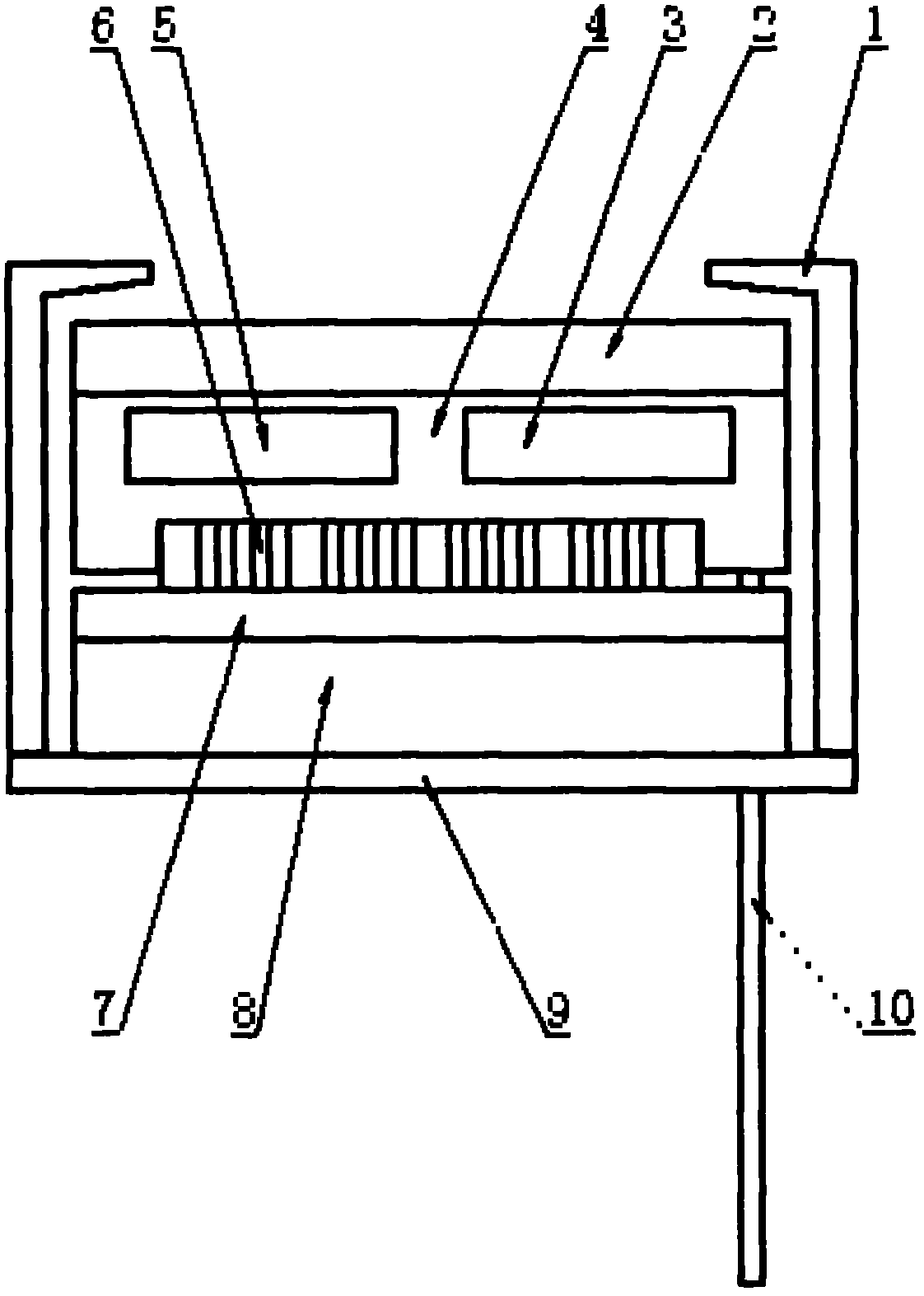

[0020] As shown in the figure, the cathode involved in the present invention includes a cathode base plate 9 supporting the overall structure, a coaxial cable 10 for transmitting power source power, a polytetrafluoroethylene insulator 8, a yoke iron 7 for limiting the magnetic circuit, a magnet 6, and a cathode body 4 and the integrated cooling units 3 and 5, the target 2 and the anode cover 1. The insulator 8 is fixed on the cathode bottom plate 9; the cathode main body 1 has a cold water tank (water inlet tank 3 and water outlet tank 5) inside to form a cooling unit; the magnets 6 are directly arranged on the yoke iron 7 to form a magnetic field unit, and the whole is fixed on the cathode main body 1, the front end of the cathode main body 4 is directly in contact with the sputtering target 2, placed on the insulator 8 as a whole, and insulated from the cathode base plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com