Novel cocoon cooking aid and its application

A cocoon aid and cocoon cooking technology, which is applied in textiles and papermaking, fiber treatment, silk reeling, etc., can solve the problems of cocoon cooking aids that have not been reported in relevant literature, so as to improve performance and grade, and increase the unwinding rate , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

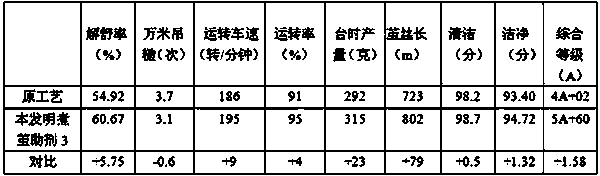

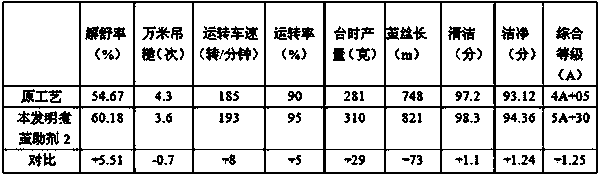

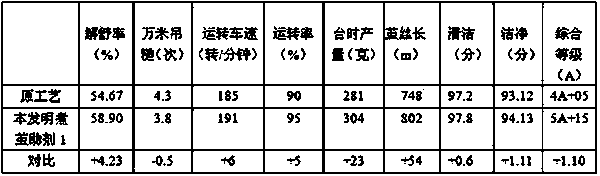

Examples

Embodiment 1

[0020] A new cocoon cooking aid, the cocoon cooking aid is mixed with the following raw materials in weight percentage, castor oil sodium sulfonate 70-80%, the balance of water, the pH value of the cocoon cooking aid is 6.8-8.0 .

Embodiment 2

[0022] A new cocoon cooking aid, the cocoon cooking aid is mixed by the following raw materials in weight percentage, ricinoleic acid imidazoline 60-80%, the balance of water, the pH value of the cocoon cooking aid is 6.5-7.5 .

Embodiment 3

[0024]A new cocoon cooking aid, which is made of the following raw materials by weight percentage, polyoxyethylene castor oil 70-90%, water balance, the pH value of the cocoon cooking aid is 6.5-8.0 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com