Method for extracting spinnable collagenous fiber from leather corner waste and waste leather

A technology of leftover waste and collagen fibers, which is applied in fiber treatment, decomposition of fiber-containing substances, textiles and papermaking, etc., can solve the problem of unsatisfactory extraction efficiency, fiber length, strength and subsequent application, difficulty in popularization and application, and fiber itself In order to improve the uniformity of fiber separation, solve the problem of low extraction efficiency and uniform length distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

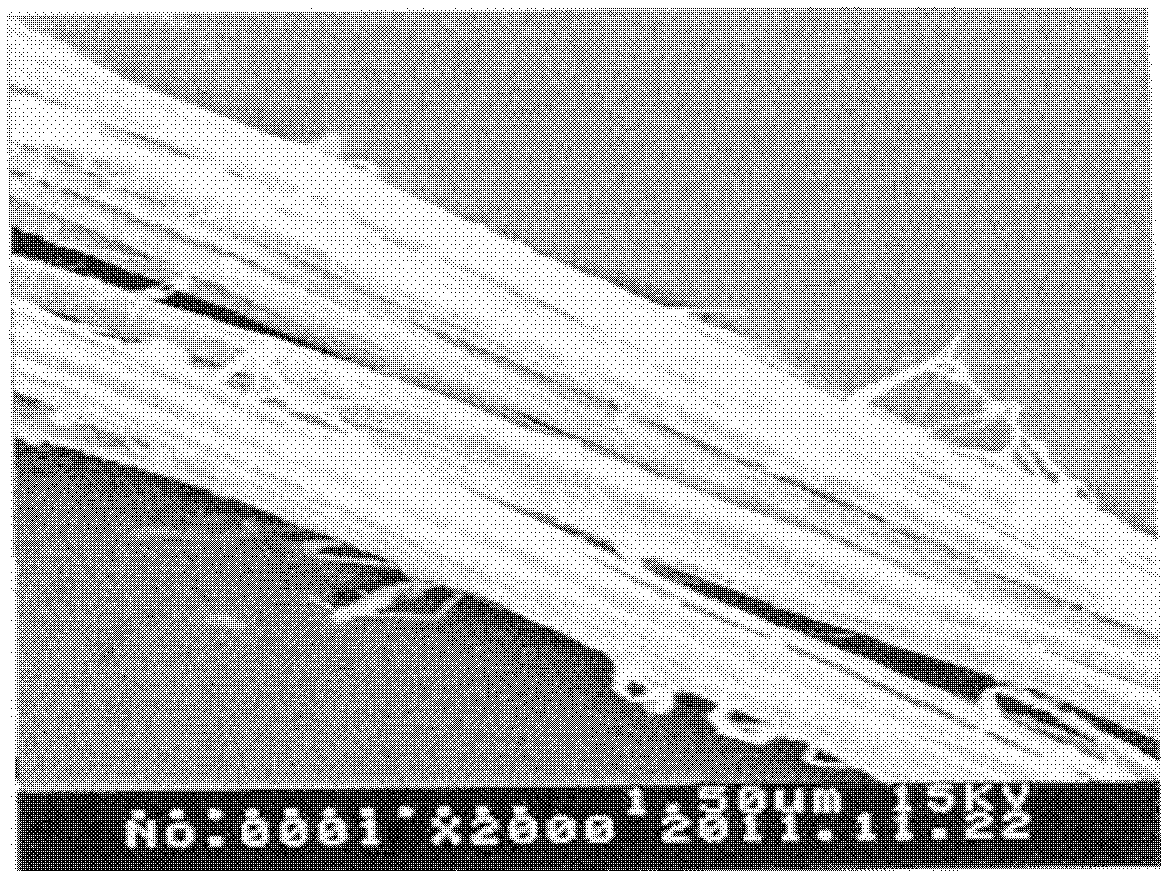

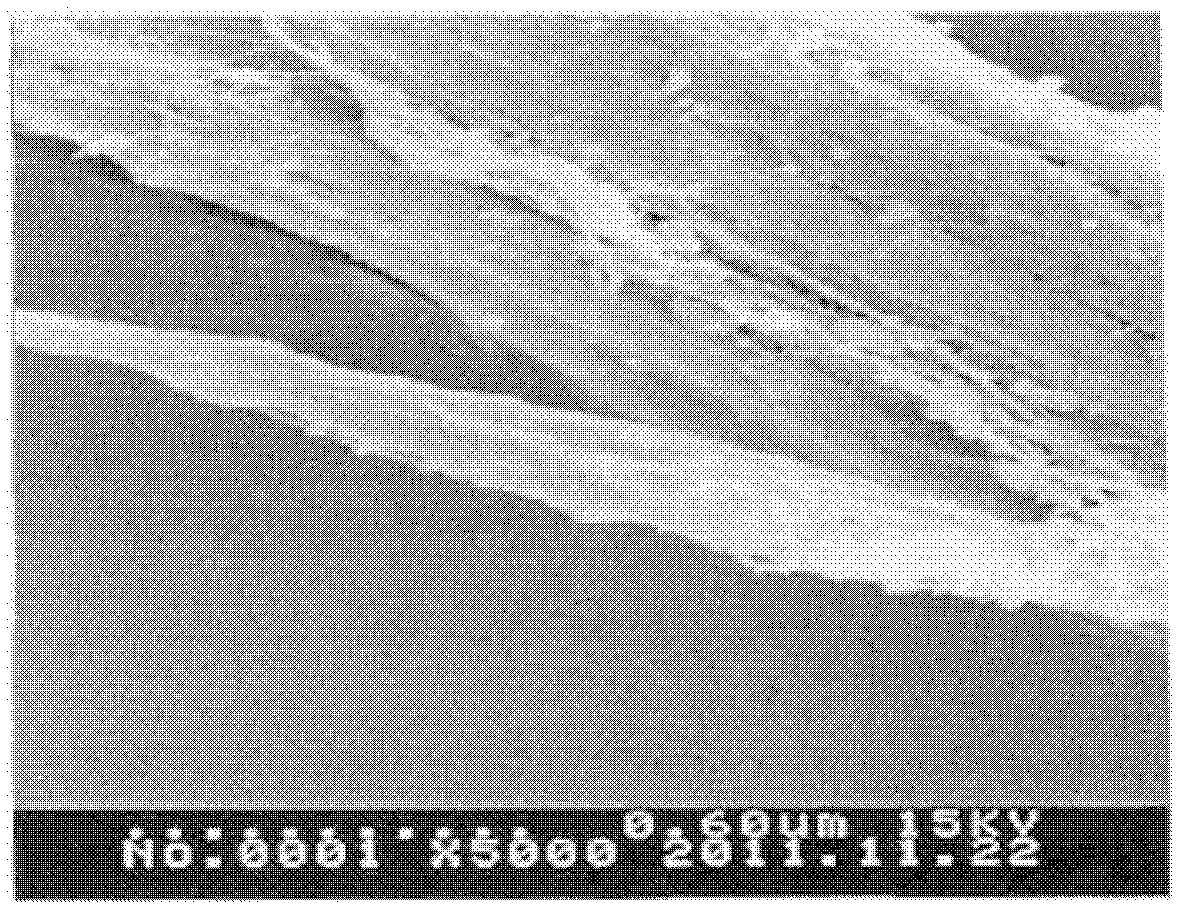

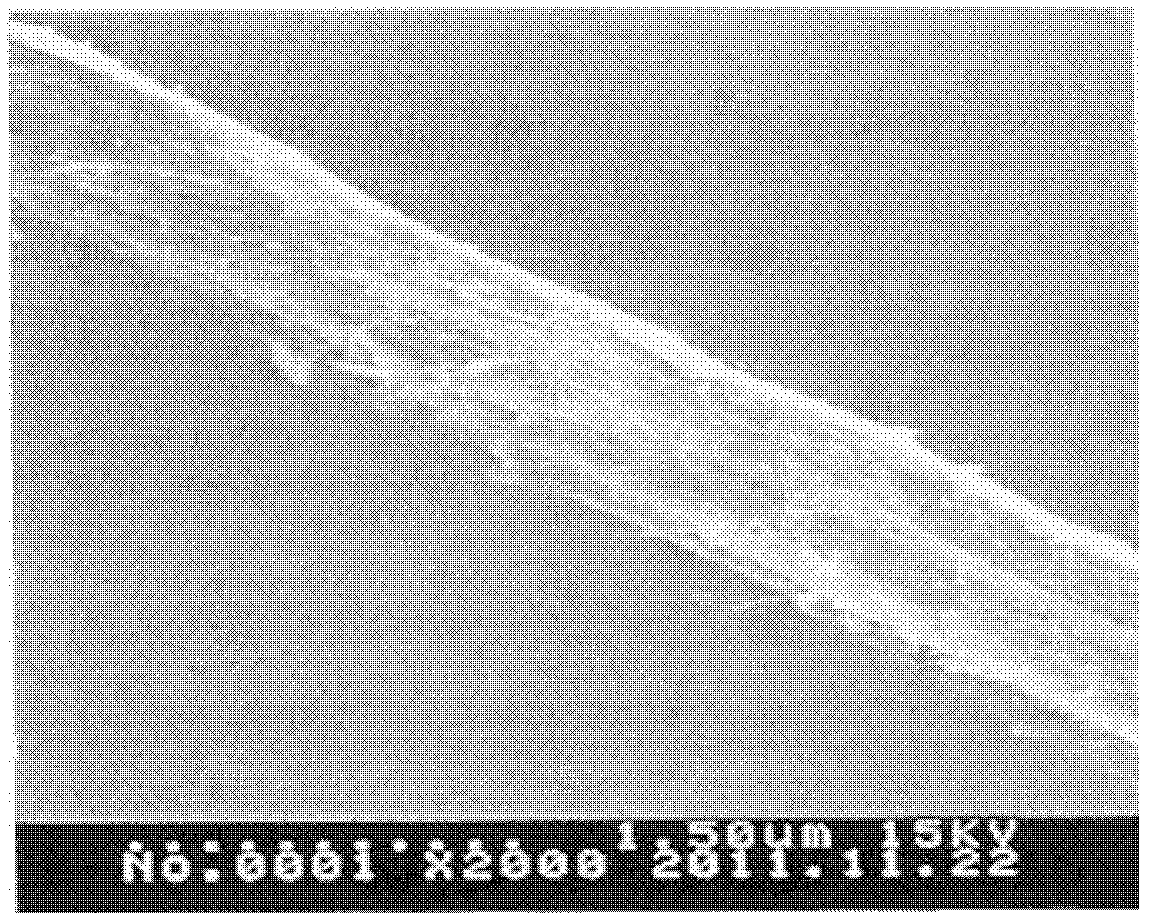

Image

Examples

Embodiment 1

[0026] Prepare collagen fibers according to the following steps:

[0027] (1) Water soaking of raw materials: Soak leather corner waste or waste leather at room temperature for 2 days;

[0028] (2) Broken material: break the soaked large raw material into small pieces with a specification of 10×20cm;

[0029] (3) Wet fiber extraction: put the scrap and water into the beater according to the mass ratio of 3:10, and operate for 60 minutes to obtain pasty collagen fibers with a water filling degree of 258%;

[0030] (4) Squeezing and stretching: spread the pasty collagen fibers on a pass-through water squeezing machine and squeeze water, and the water content after water squeezing is 64%.

[0031] (5) Fiber spreading: Put the collagen fibers obtained after water squeezing into a y-shaped stainless steel drum and rotate for 50 minutes to evacuate and loosen the agglomerated or agglomerated fibers. At the same time, the heating and ventilation device in the y-shaped stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com