Processing method of ready-made garment with washed effect and ready-made garment processed by same

A processing method and garment technology, applied in protective clothing, dyeing methods, special outerwear, etc., can solve the problems of not being bright enough, high cost, and inability to dye colors, and achieve the effect of short dyeing time, complete color spectrum, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

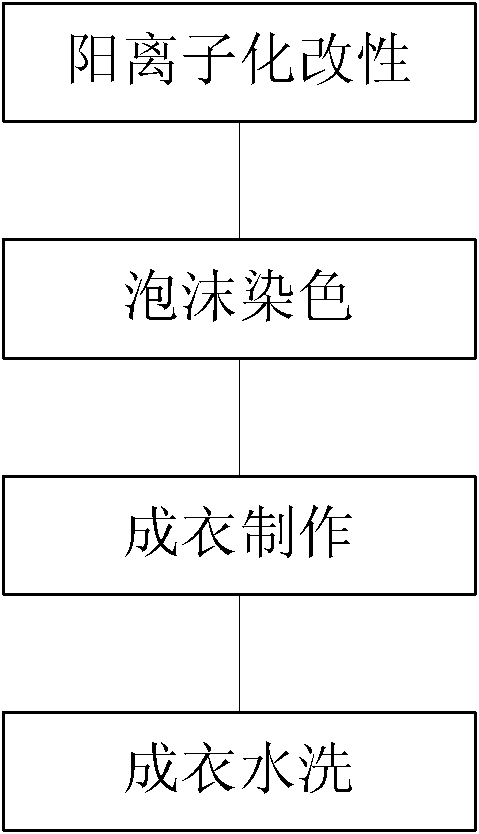

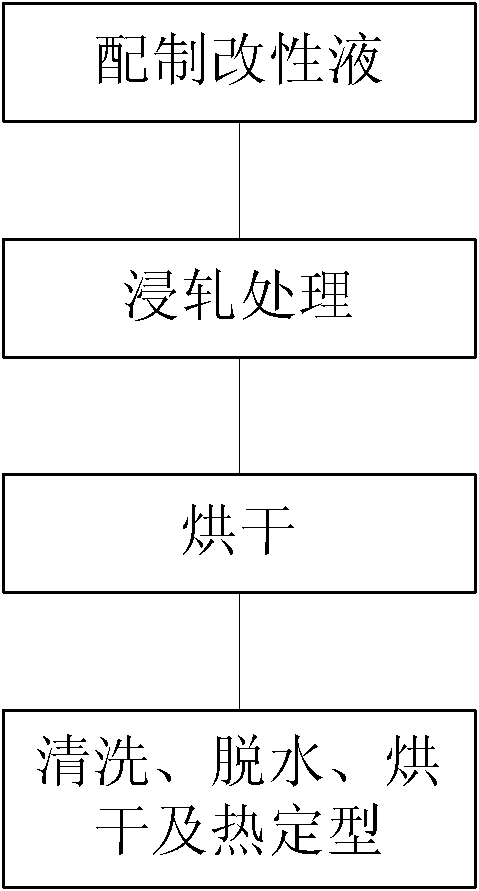

[0075] 1. Cationic modification

[0076] (1) Prepare a modified padding solution of 60g / L cationic modifier Indosol E50 and 60g / L sodium carbonate, and heat it properly when preparing the solution to help the dissolution of the polymer cationic modifier.

[0077] (2) At room temperature, the knitted cotton cloth (pure cotton interlock fabric, 250g / m 2 ) in the padding liquid for two dipping and two rolling treatments, and the control liquid volume is 70%.

[0078] (3) Dry the knitted cotton cloth coated with the modifying solution at 120° C. for 2 minutes.

[0079] (4) Wash the dried fabric twice in warm water at 60°C, and then once in cold water at room temperature, each time for 5 minutes. The fabric is then dehydrated, dried and heat-set for dyeing.

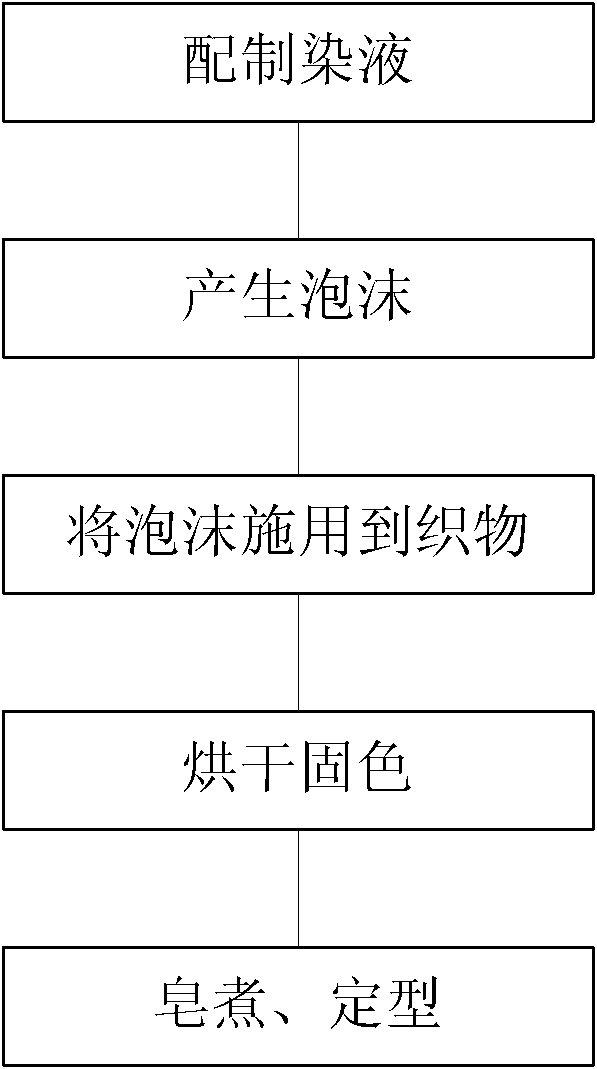

[0080] 2. Foam Dyeing

[0081] (1) prepare dye liquor, contain the C.I. reactive red 239 of 50g / L in the dye liquor, the soda ash of 15g / L, the sodium lauryl sulfate of 15g / L and the hydroxyethyl cellulose of 5g / L. Before...

Embodiment 2

[0091] 1. Cationic modification

[0092] (1) Prepare a padding solution of 60g / L cationic modifier Indosol E50 and 60g / L soda ash, and heat it properly during the liquid preparation to help the dissolution of the polymer cationic modifier.

[0093] (2) At room temperature, the woven cotton cloth (pure cotton twill, 250g / m 2 ) in the padding liquid for two-dipping and two-rolling treatment, and the control liquid volume is 70%.

[0094] (3) Dry the knitted cotton cloth coated with the modifying solution at 120° C. for 2.5 minutes.

[0095] (4) Wash the dried fabric twice in warm water at 60°C, and then once in cold water at room temperature, each time for 5 minutes. The fabric is then dehydrated, dried and heat-set for dyeing.

[0096] 2. Foam dyeing process

[0097] (1) Prepare the dyeing solution, containing 50g / L Noviclon navy blue S-G (Huntsman), 15g / L sodium carbonate, 15g / L sodium lauryl sulfate and 5g / L hydroxyethyl cellulose in the dyeing solution white. Before th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com