A prefabricated composite reinforced concrete arch culvert

A reinforced concrete and prefabricated assembly technology, applied in the field of culverts, can solve problems such as many construction joints, easy flow of cement slurry, and difficult to predict, and achieve the effects of reducing project cost, speeding up roadbed construction, and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

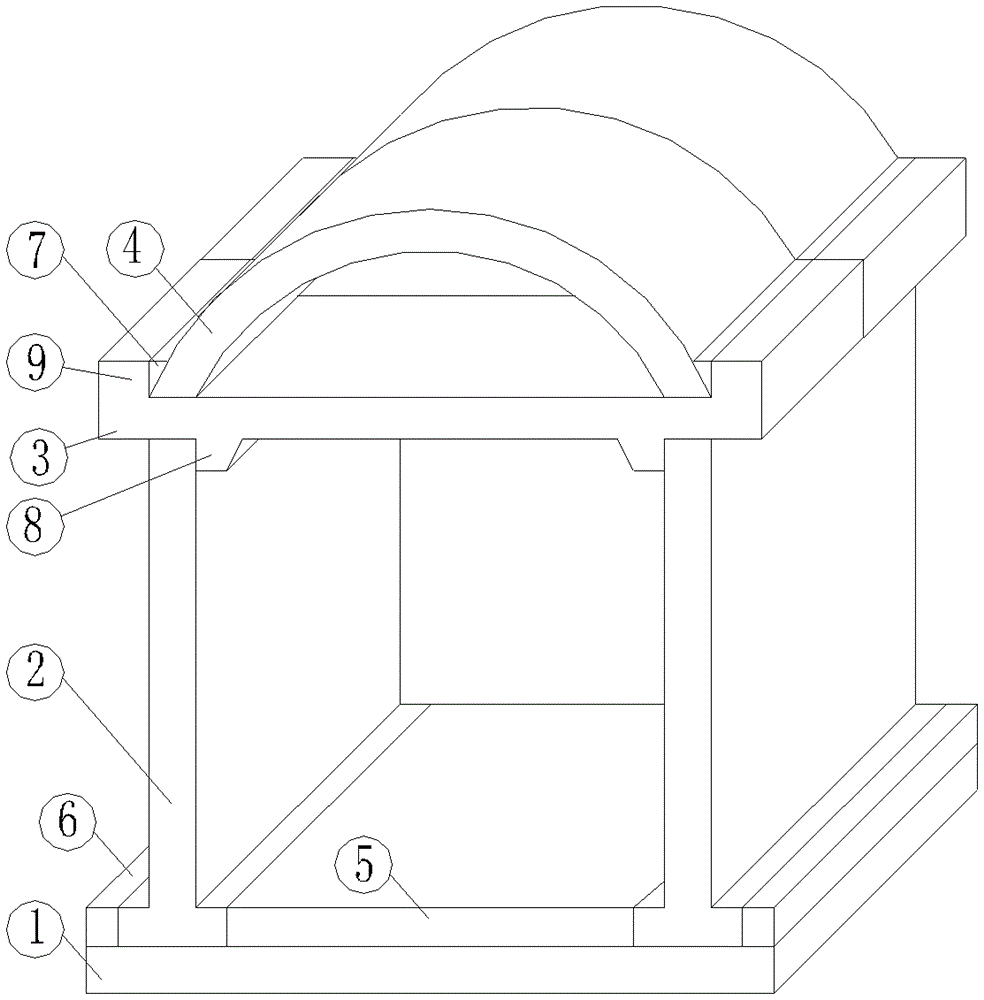

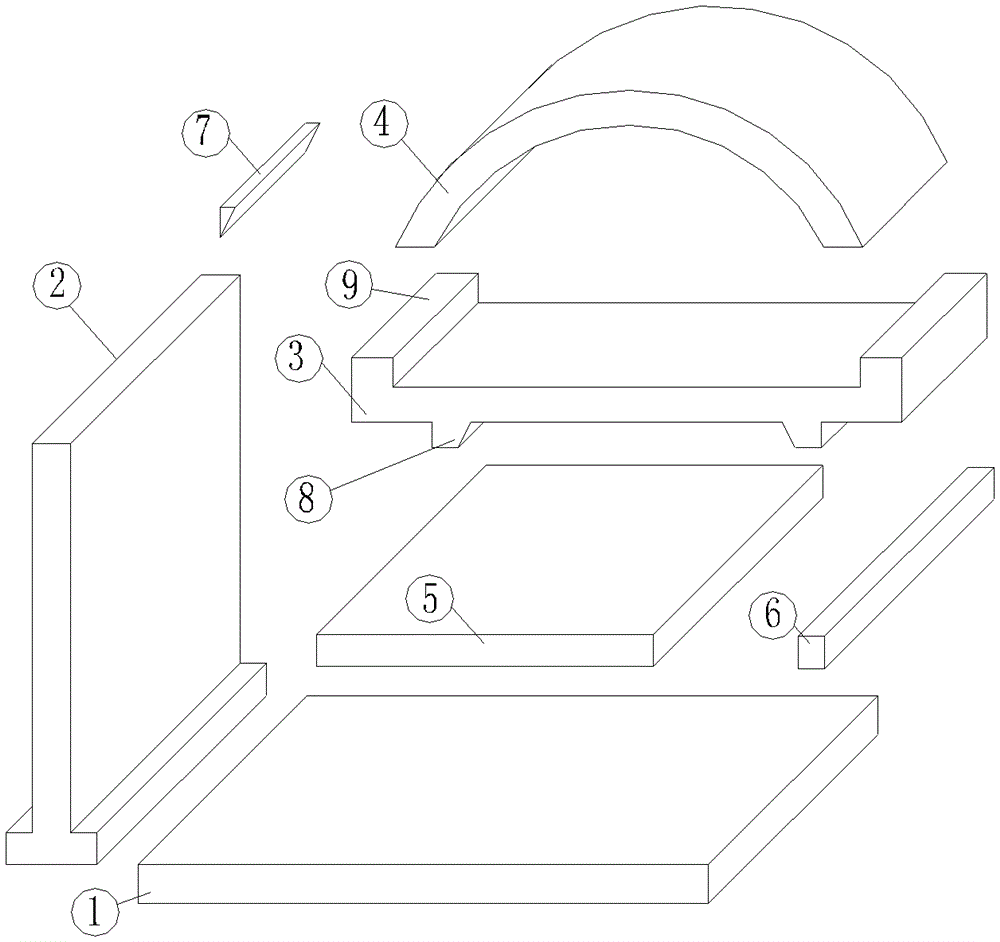

[0016] The present invention is shown in the accompanying drawings: cast-in-situ reinforced concrete foundation 1, prefabricated inverted T-shaped wall panels 2, prefabricated cover panels with corner legs 3, prefabricated arch panels 4, post-cast reinforced concrete inner bottom slabs 5 inside the cave, and post-cast concrete panels outside the cave. Pour reinforced concrete side strips 6, post-cast reinforced concrete triangular strips 7, lower corner legs 8, upper corner legs 9. First construct the cast-in-place reinforced concrete foundation 1, draw the hoisting positioning line on the cast-in-place reinforced concrete foundation 1, hoist the prefabricated inverted T-shaped wall panels 2 on both sides of the culvert, fine-tune, align, and pad the prefabricated inverted T-shaped wall panels 2, Hang the prefabricated cover plate 3 with corner legs on the prefabricated inverted T-shaped wall panels 2 on both sides, connect the reserved steel bars of the prefabricated inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com