Optimization cooperative control method for discharge of nitrogen oxides and particles of high-pressure common-rail diesel

A high-pressure common rail, collaborative control technology, applied in engine control, program control, electrical control, etc., can solve problems such as increased emissions, high manufacturing and use costs, dimensional disaster, etc., and achieve the effect of reducing burden and requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

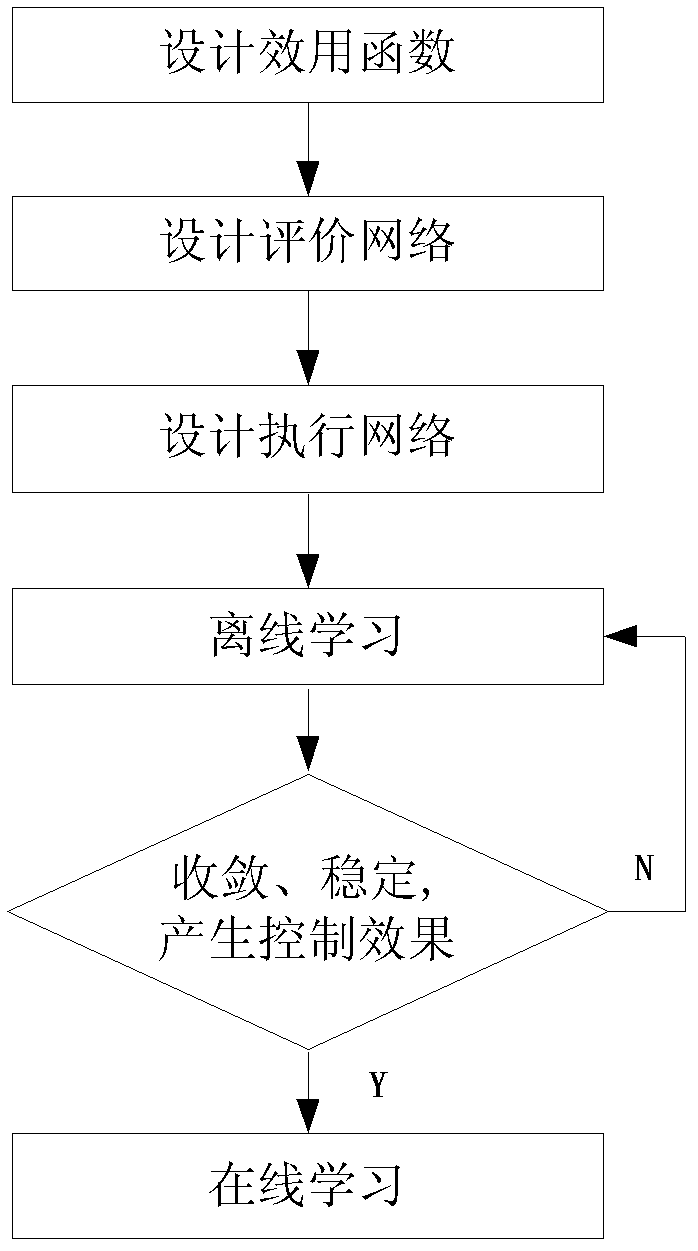

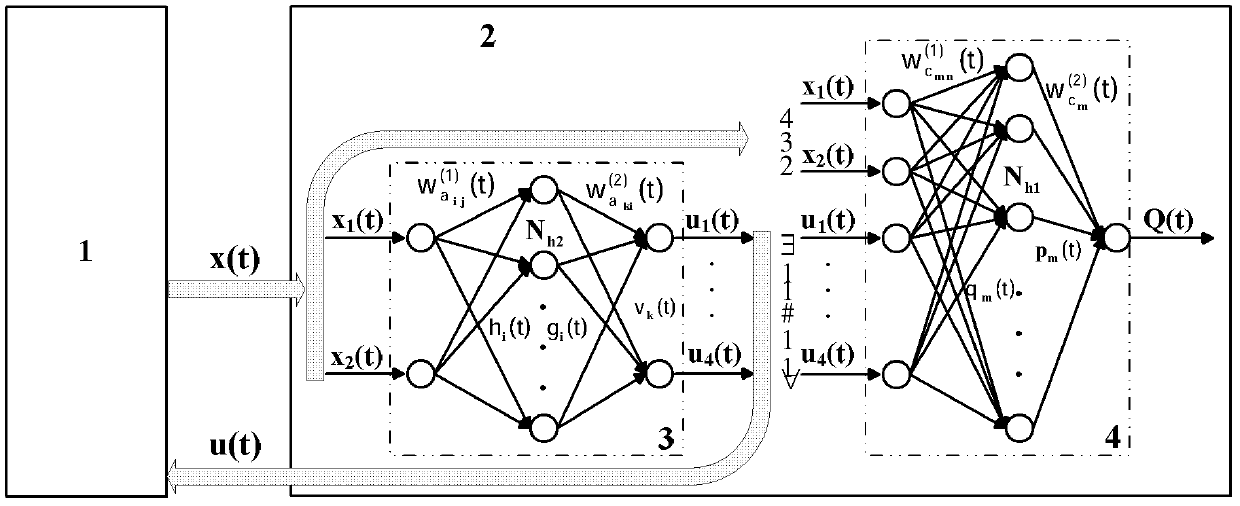

[0021] The concrete implementation of the present invention will be further described below in conjunction with accompanying drawing: figure 1 , figure 2 Shown, the implementation steps of the inventive method are:

[0022] 1. Design utility function

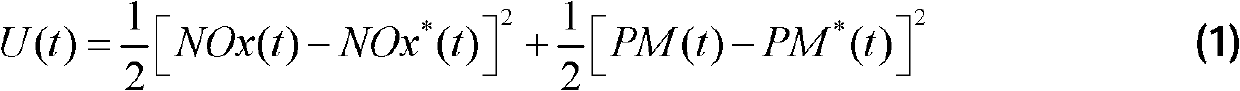

[0023] The utility function U(t) is defined as:

[0024]

[0025] Here NOx(t) and PM(t) are diesel engine NOx at sampling time t X and PM emissions real-time measurements; NOx * (t) and PM * (t) means diesel engine NO at sampling time t X and the optimal target value of PM emissions.

[0026] The emission parameters of NOx and PM are measured by the orthogonal experiment method at startup and under various working conditions, and then the reasonable NOx and PM emission optimization targets of diesel engines under various working conditions can be formulated according to the actual measurement results and the National IV emission standards Value NOx * (t) and PM * (t).

[0027] 2. Evaluate network design

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com