Self-pressurization energy recovery high-pressure pump for reverse osmosis sea water desalinization

An energy recovery and self-pressurization technology, applied in the field of high-pressure pumps, can solve the problems of high efficiency, uneconomical investment, and difficulty in selection, and achieve the effect of simple design process, reduced energy consumption and equipment investment, and reduced volume and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

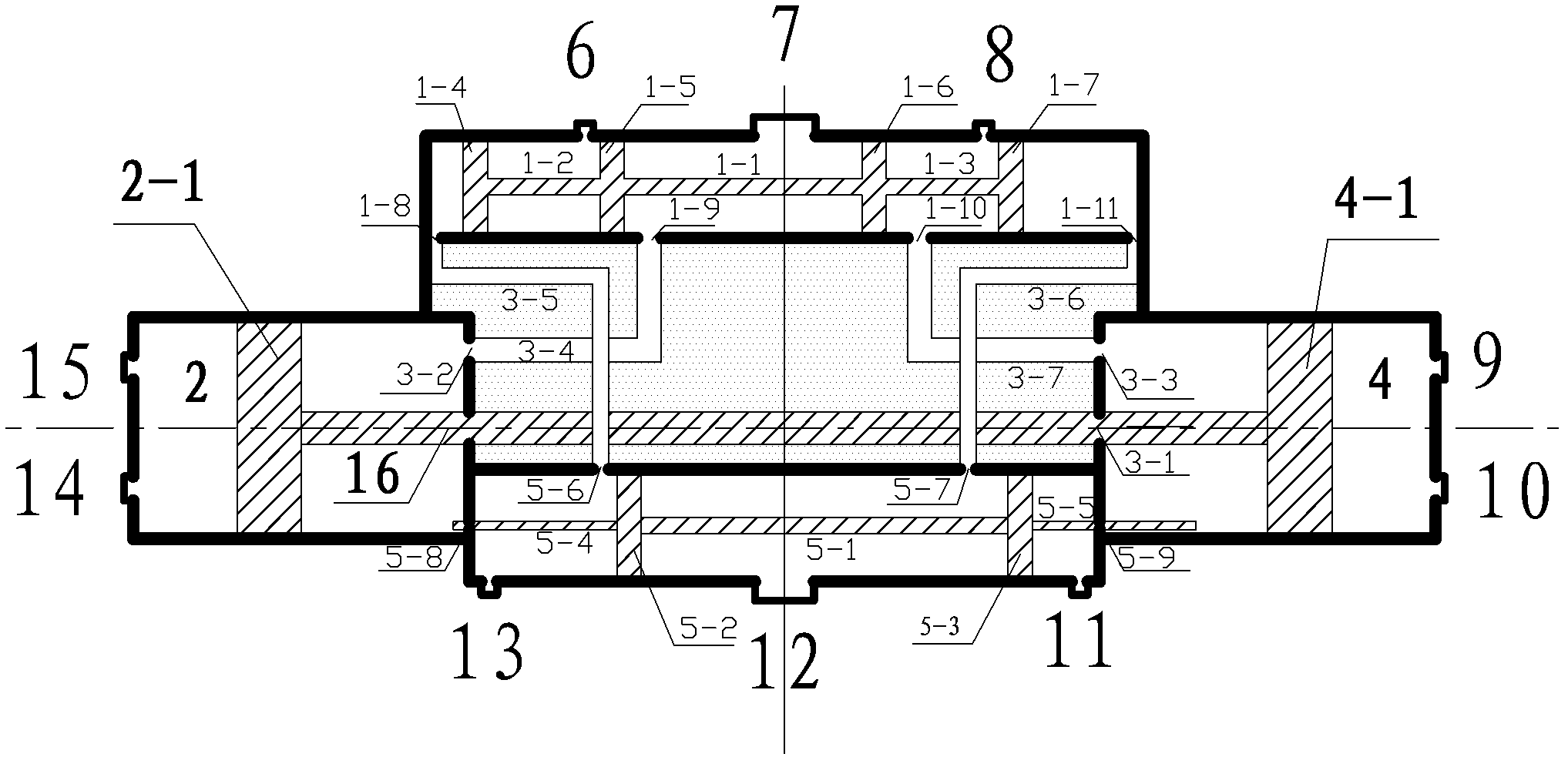

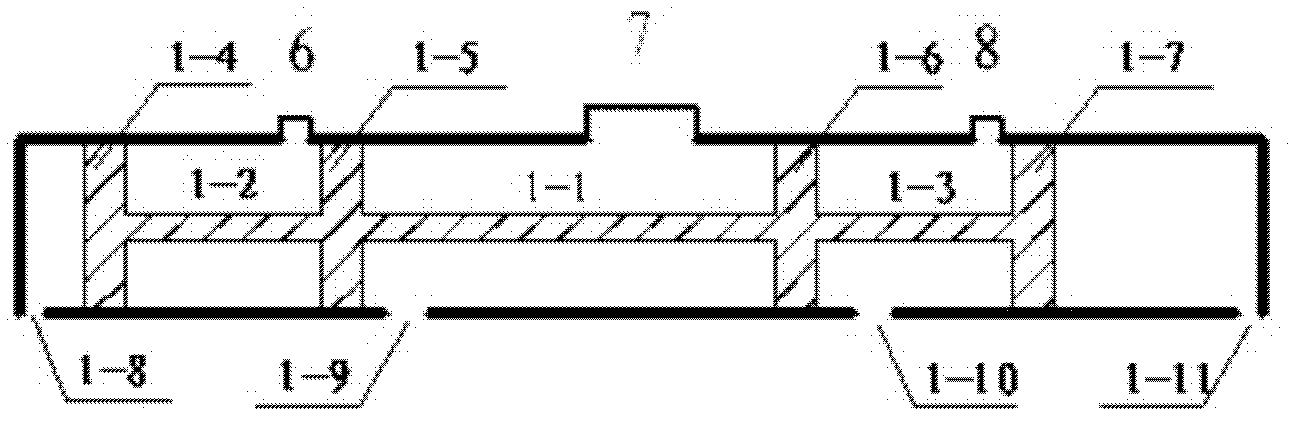

[0057] The self-pressurized energy recovery high-pressure pump for reverse osmosis seawater desalination of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0058] Such as figure 1 , figure 2 As shown, the reverse osmosis seawater desalination self-boosting energy recovery high-pressure pump of the present invention includes: a central block 3, located at the center of the reverse osmosis seawater desalination self-boosting energy recovery high-pressure pump, forming a plurality of internal flow channels inside; The direction control valve 1 is located above the central block 3, communicates with the internal flow passage of the central block 3, and is provided with a high-pressure brine hole 7 and a first discharge hole 6 and a first discharge hole 6 symmetrically located on both sides of the high-pressure brine hole 7 The second discharge hole 8; the pilot control valve 5, located below the center bloc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap