Intelligent X-ray digital flat imaging detection system device and detection method

A digital imaging system and digital flat panel technology, applied in the direction of material analysis using radiation, can solve the problems of inability to accurately locate workpieces, inability to perform global inspection, and low inspection efficiency, achieving high automation, high positioning accuracy, and reduced labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

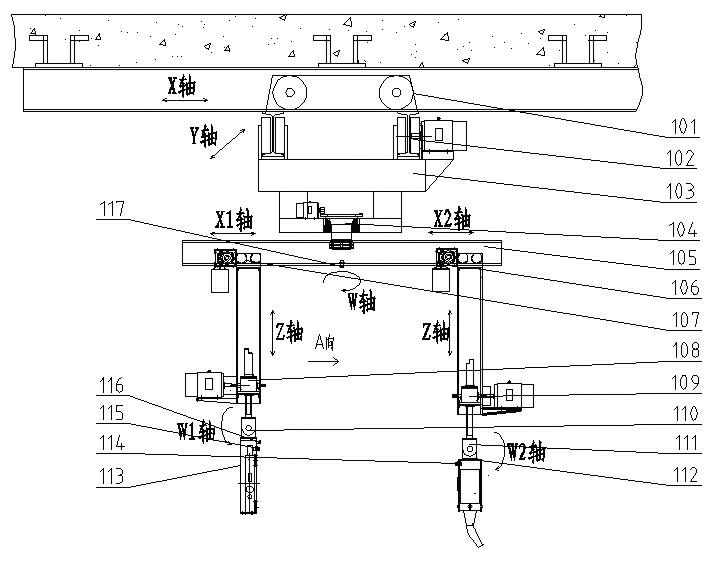

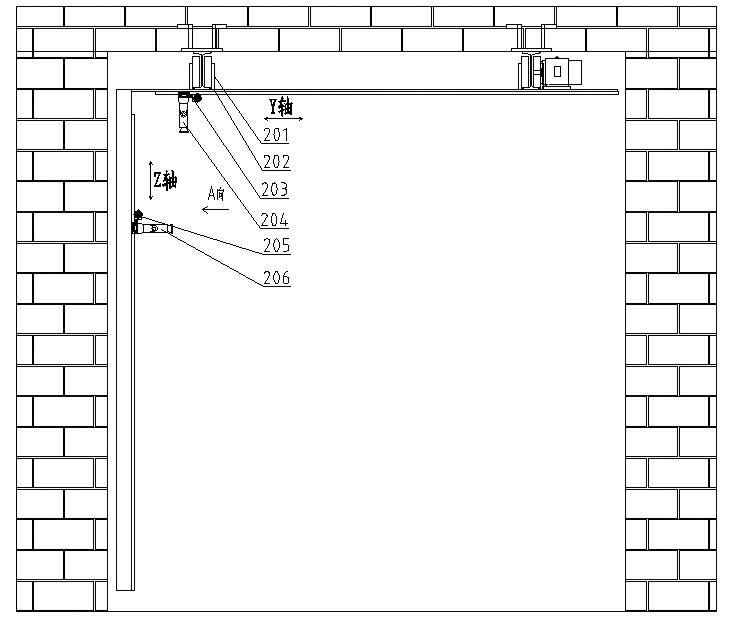

[0027] The structural composition and method principles of the present invention are illustrated in conjunction with the accompanying drawings.

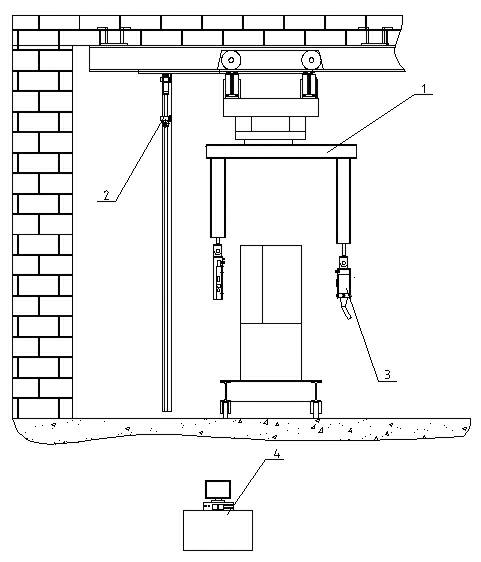

[0028] An X-ray digital flat panel imaging intelligent detection system device, such as figure 1 As shown, it is composed of four parts: a multi-axis mobile robot arm 1 , an imaging scanning positioning device 2 , a flat-panel X-ray digital imaging system device 3 , and a system console 4 . After the information is fed back and summarized through the system console 4, the drive control command is sent, and the camera scanning positioning device 2 is driven successively to perform system scanning and positioning, and then the workpiece contour positioning and welding seam position positioning of the system software are used to determine and compile the automatic detection program , drive the multi-axis mobile robot arm 1 to move the flat-plate X-ray digital imaging system device 3 to move along the predetermined track, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com