Temperature switch based on phase change and volume change effect of low-melting point metal

A low-melting-point metal and temperature switch technology, which is applied to thermal switch components and other directions, can solve the problems of no substantive innovation, etc., and achieve the effects of large pressure resistance, long-term stable operation, and rapid temperature rise and fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

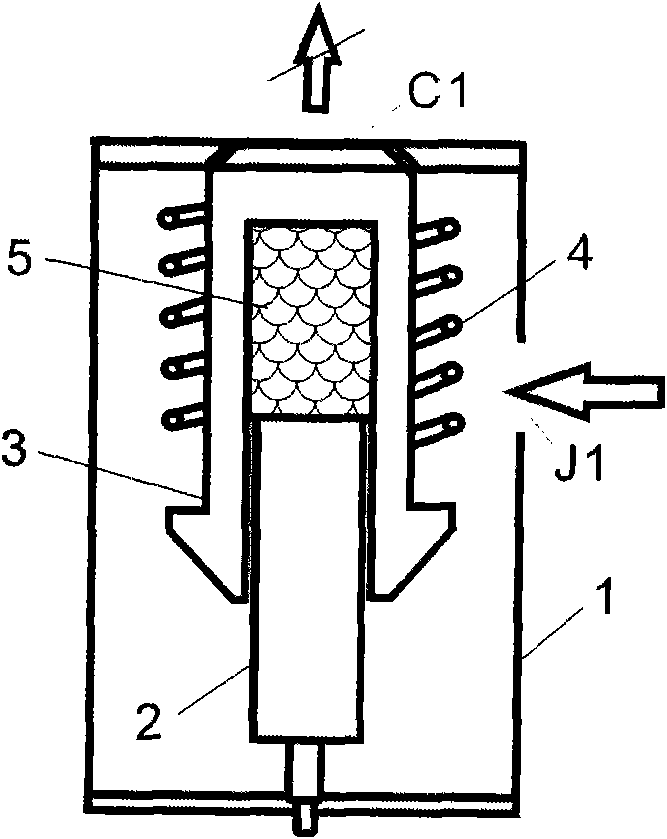

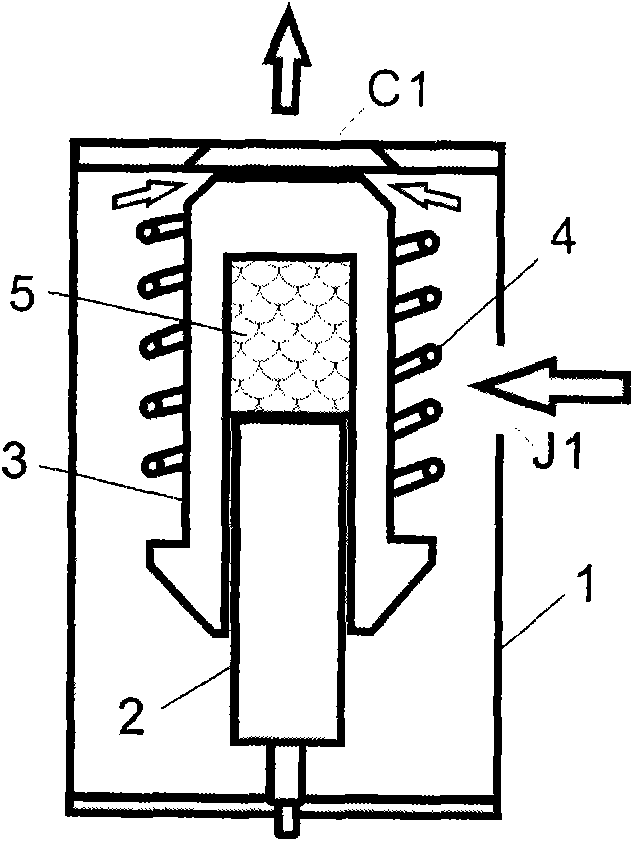

[0034] Embodiment 1 shows a typical application of the temperature switch based on the volume change effect of the phase transition of the low melting point metal of the present invention. figure 1 It is a structural schematic diagram when the temperature switch is in a closed state; figure 2 It is a structural schematic diagram when the temperature switch is in an open state.

[0035] Such as figure 1 with figure 2 As shown, the low melting point metal phase transition temperature switch of the present embodiment consists of a hollow housing 1, a fixed rod 2, a hollow piston 3, a spring 4, and a space 5 filled between the top of the fixed rod 2 and the inner top of the hollow piston 3 The liquid metal composition in

[0036] In this embodiment, a fluid inlet J1 is provided on the side wall of the hollow housing 1 and a fluid outlet C1 is opened on the top wall of the hollow housing 1;

[0037] The fixed rod 2 is vertically fixed on the inner bottom end wall of the hollo...

Embodiment 2

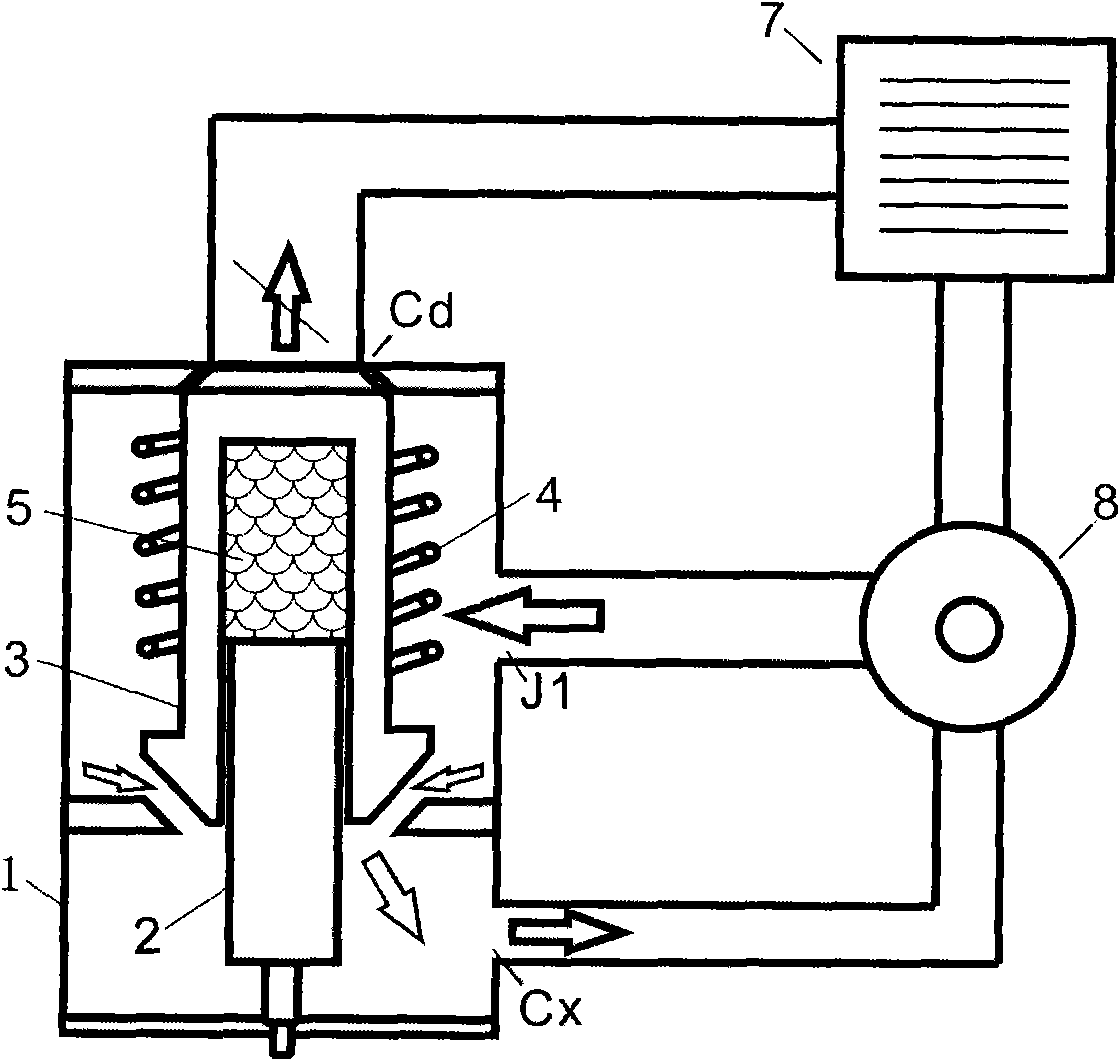

[0046] Embodiment 2 shows a typical application of the temperature switch based on the phase transition volume change effect of the low melting point metal of the present invention as an automobile thermostat; image 3 , Figure 4 A schematic diagram of its structure.

[0047] Such as image 3 with Figure 4 As shown, the structure of the temperature switch based on the low-melting point metal phase transition volume change effect of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0048] A fluid inlet J1 and two fluid outlets (a small circulation outlet Cx located at the bottom of the side wall of the hollow housing 1 and a large circulation outlet Cd located on the top wall of the hollow housing 1) are provided on the hollow housing 1; The heated cooling water of the automobile engine 8 flows in from the fluid inlet J1 located in the middle of the side wall of the hollow casing 1, and the hot water flowing out through the small circulati...

Embodiment 3

[0053] Example 3 shows a typical application of the temperature switch based on the phase transition volume change effect of the low-melting point metal of the present invention as a thermostatic water mixing valve. Figure 5 A schematic diagram of adjusting the mixing ratio of cold and hot water for the thermostatic mixing valve to ensure a constant outlet water temperature.

[0054] Such as Figure 5 As shown, the structure of the temperature switch based on the volume change effect of the low-melting point metal phase transition in this embodiment is basically the same as that in Embodiment 1, the difference is:

[0055] This embodiment has two fluid inlets (hot water inlet J1 and cold water inlet J2) and one fluid outlet (mixed water outlet C1). Cold and hot water enter from their respective inlets, mix in the water mixing valve, and then flow out through the mixing water outlet C1.

[0056] The materials of the hollow casing 1, the fixed rod 2 and the hollow piston 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com