Method for monitoring potentials of anode and cathode of lithium-ion battery

A lithium-ion battery, positive and negative electrode technology, which is applied in the field of effectively monitoring the positive and negative voltages of lithium-ion batteries, can solve the problems of potential drift, the third electrode is easily affected by external factors, and the production process is cumbersome, and achieves simple production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of working cell 1:

[0044] Preparation of positive electrode sheet:

[0045] The positive electrode active material lithium cobalt oxide (LiCoO 2 ), the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) were added to the solvent N-methylpyrrolidone (NMP) in a mass ratio of 96:1.5:2.5 to disperse evenly to prepare the positive electrode slurry. Then, the positive electrode slurry was coated on the Al foil (12 μm in thickness), and operations such as rolling, slicing, drying and welding of the positive electrode tab 11 were performed to obtain the positive electrode sheet.

[0046] Preparation of negative electrode sheet:

[0047] Negative electrode active material graphite, conductive agent acetylene black, binder styrene-butadiene rubber emulsion and thickener sodium carboxymethyl cellulose are added to solvent water according to the mass ratio of 94:1.5:2.5:2 and mixed evenly, and the negative electrode is prepared after sti...

Embodiment 2

[0055] The preparation of the working cell 1 is the same as that in Example 1.

[0056] The preparation of reference battery cell 2, reference battery cell 2 is a negative electrode sheet, and its preparation method is as follows:

[0057] Add soft carbon as the negative electrode active material, acetylene black as the conductive agent, styrene-butadiene rubber emulsion as the binder, and sodium carboxymethylcellulose as the thickener according to the mass ratio of 94:1.5:2.5:2, and mix them evenly in solvent water. Negative slurry. Then the negative electrode slurry is coated on the Cu foil (thickness is 16 μm), and then roll pressing, slicing, drying and welding the first tab 21 and the second tab 22 and other operations to prepare the negative electrode sheet, that is, the reference Cell 2.

[0058] Preparation of four-electrode lithium-ion battery:

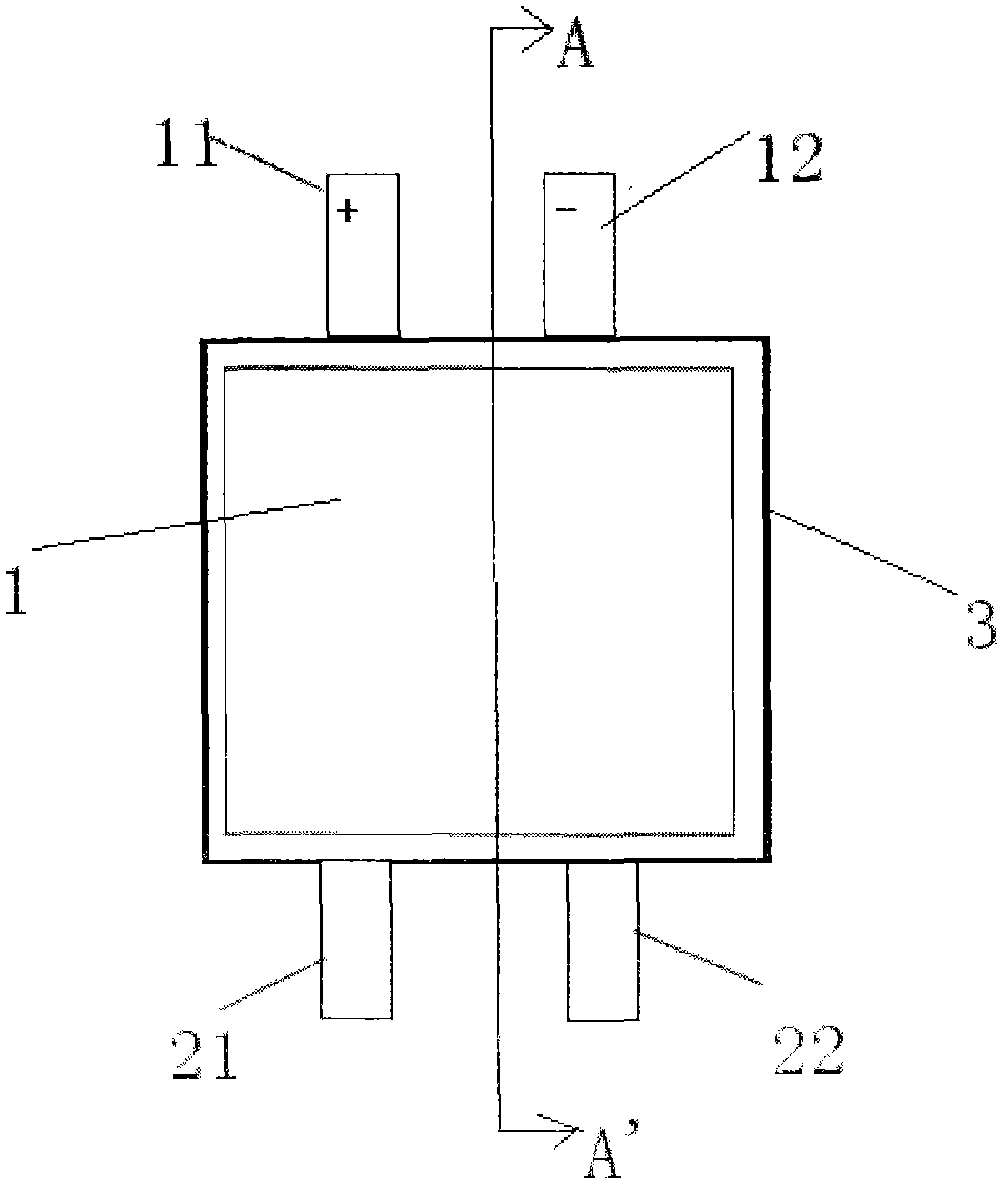

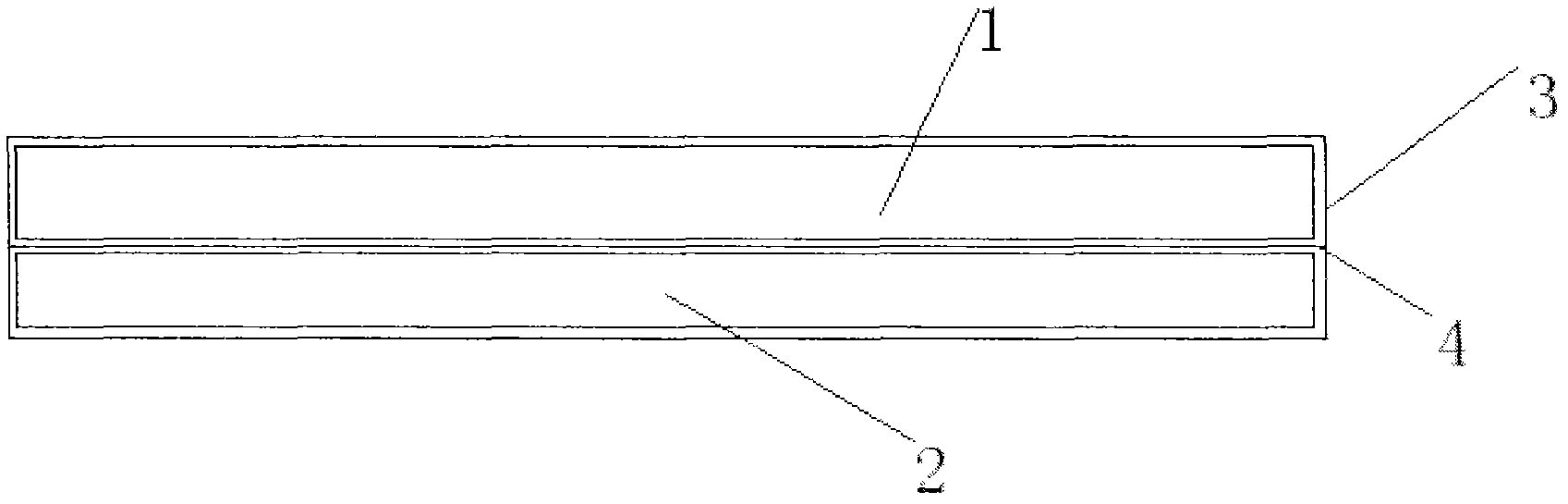

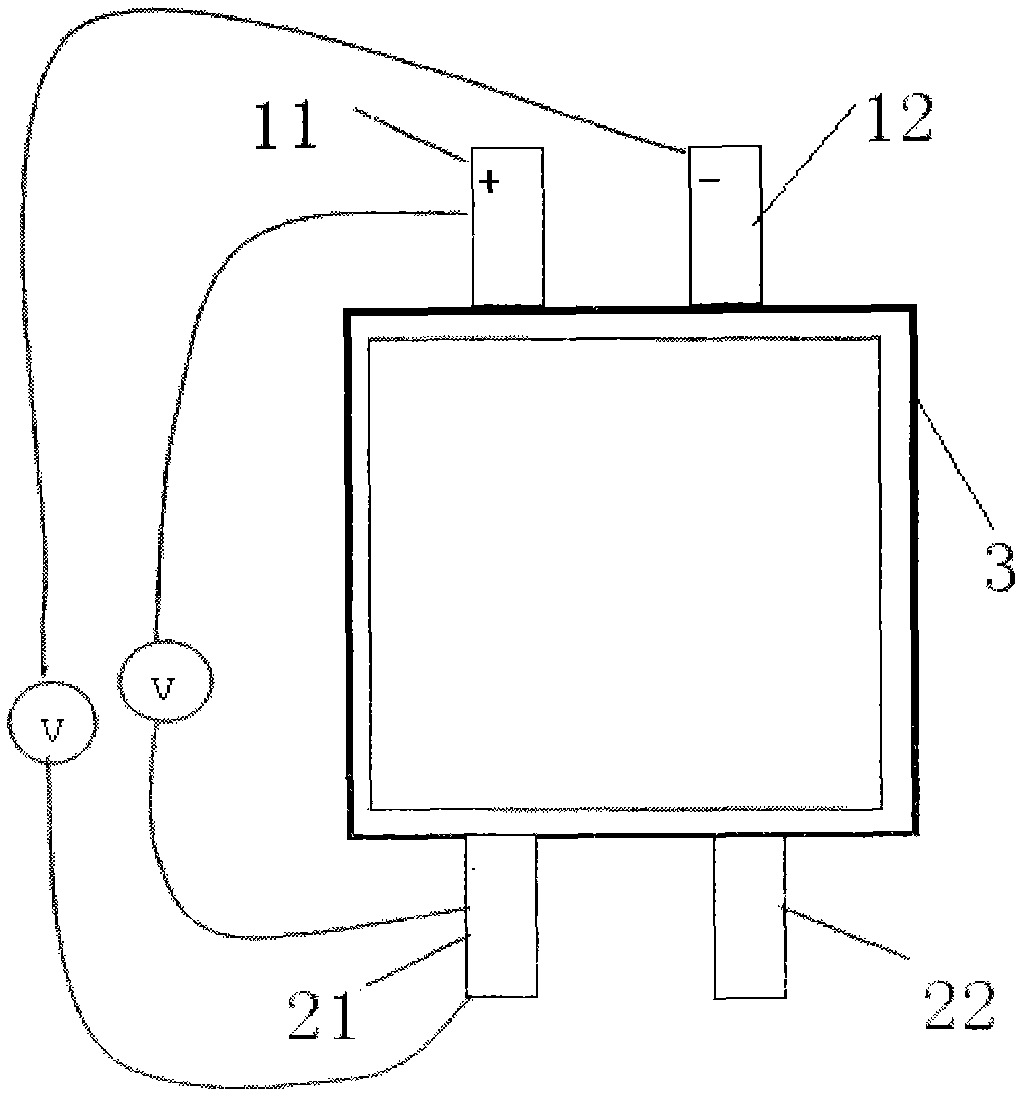

[0059] Such as figure 1 As shown, the working cell 1 and the reference cell 2 are packaged in the same packaging bag 3,...

Embodiment 3

[0062] The preparation of the working cell 1 is the same as that in Example 1.

[0063] Preparation of reference cell 2:

[0064] Preparation of positive electrode sheet:

[0065] The positive electrode active material lithium nickel cobalt manganese oxide (LiNi 0.4 co 0.4 al 0.2 o 2 ), the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) were added to the solvent N-methylpyrrolidone (NMP) in a mass ratio of 96:1.5:2.5 to disperse evenly to prepare the positive electrode slurry. Then the positive electrode slurry was coated on the Al foil (12 μm in thickness), and operations such as rolling, slicing, drying, and welding of the first tab 21 were performed to obtain the positive electrode sheet.

[0066] Preparation of negative electrode sheet:

[0067] The negative electrode active material hard carbon, the conductive agent acetylene black, the binder styrene-butadiene rubber emulsion and the thickener sodium carboxymethyl cellulose are adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com