Method for manufacturing flexible joint of large-length submarine cable

A production method and soft joint technology, applied in the direction of connecting/terminating cable equipment, etc., can solve problems such as unsatisfactory performance, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

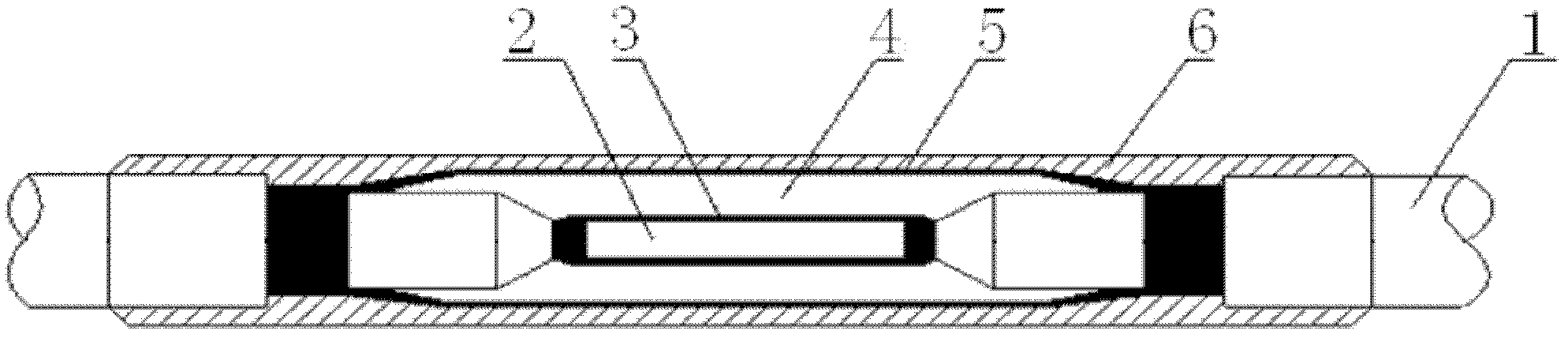

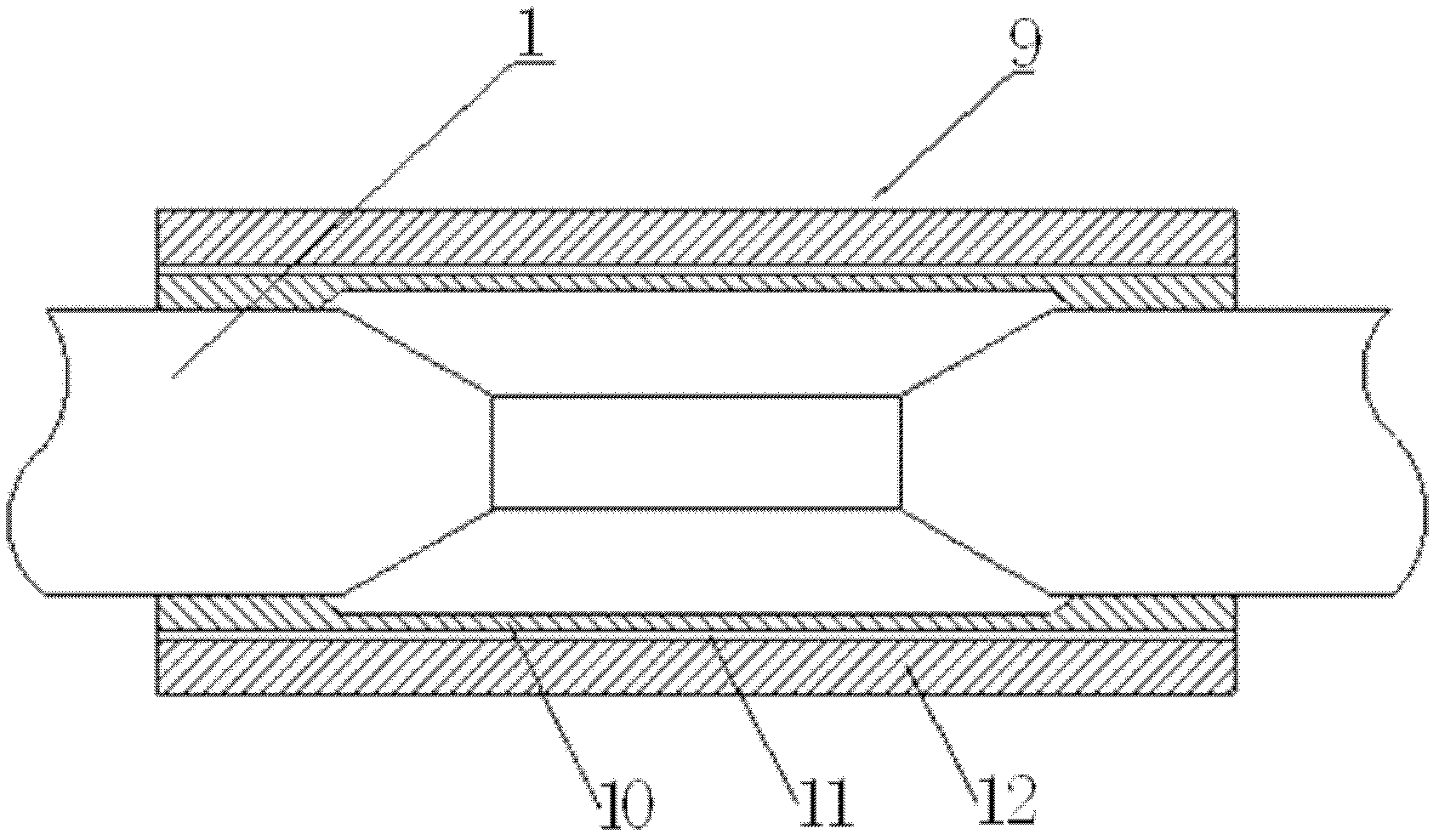

[0026] Combine below Figure 1-4 The present invention is described in further detail.

[0027] 1) Conductor connection

[0028] The welding method of argon arc welding is used to weld the conductor 2 in staggered layers, and the welded part is treated to be equal to the outer diameter of the cable conductor.

[0029] 2) Conductor shielding and vulcanization

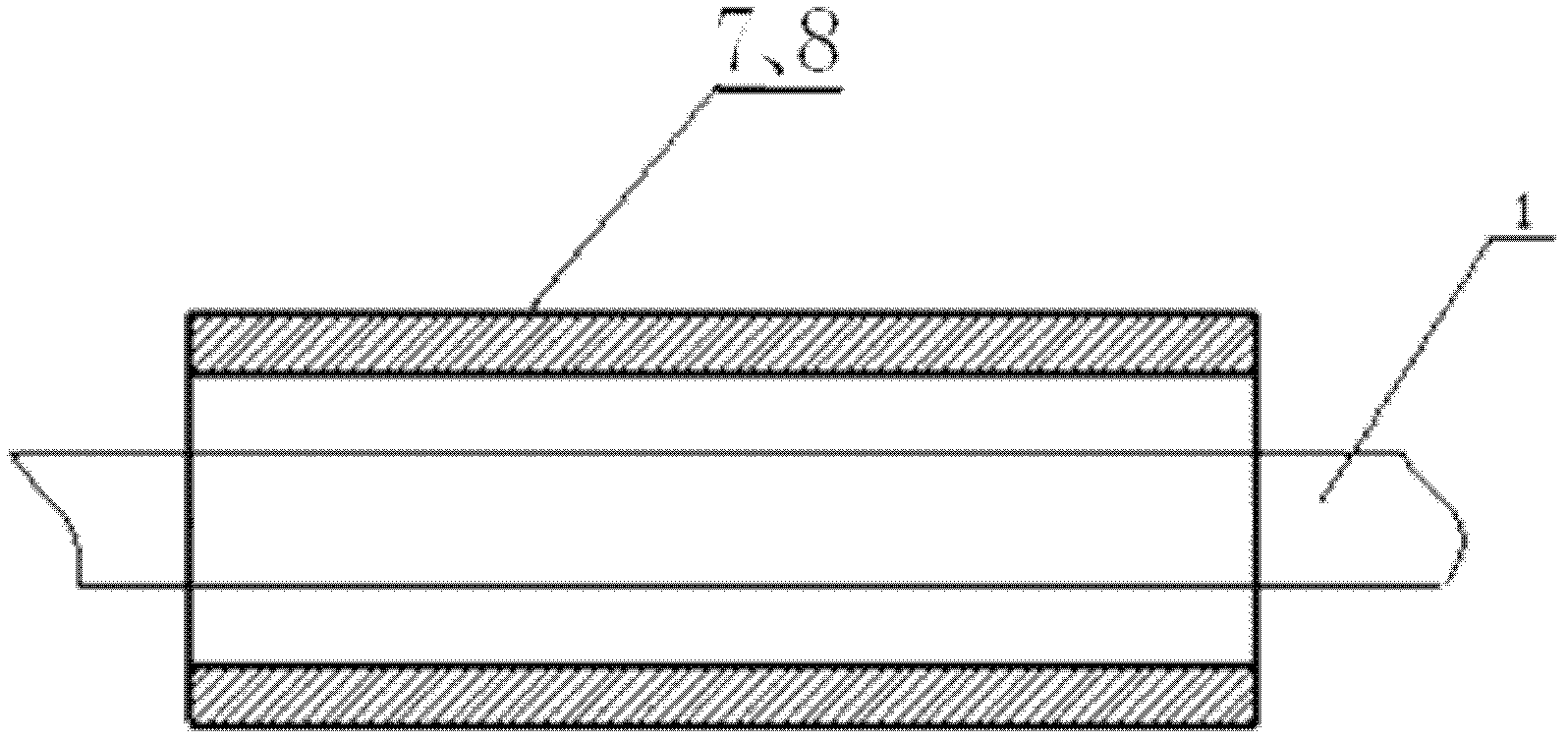

[0030] The conductor shielding layer 3 is prefabricated with special materials. The conductor shielding layer 3 adopts a half-sleeve structure, the inner diameter of the sleeve is close to the outer diameter of the conductor, and the length of the sleeve is guaranteed to overlap with the shielding of the cable conductor; The cover is wrapped with a layer of special material, which is easy to demould and fix the casing. Install the vulcanization mold 7 and heat it to the predetermined temperature (240±5°C), cut off the power supply to stop heating, and gradually tighten the vulcanization mold fastening device, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com