High-power EMI (Electromagnetic Interference) filter

A filter and high-power technology, which is applied in the field of high-power EMI filters, can solve the problem that the filter cannot meet the needs of photovoltaics, and achieve the effects of avoiding heat saturation, ensuring performance and safety, and reducing electromagnetic interference noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

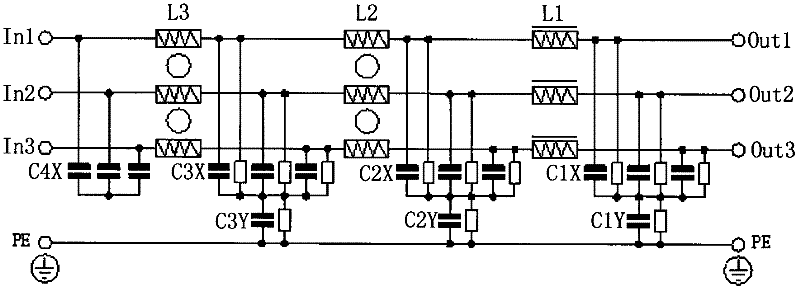

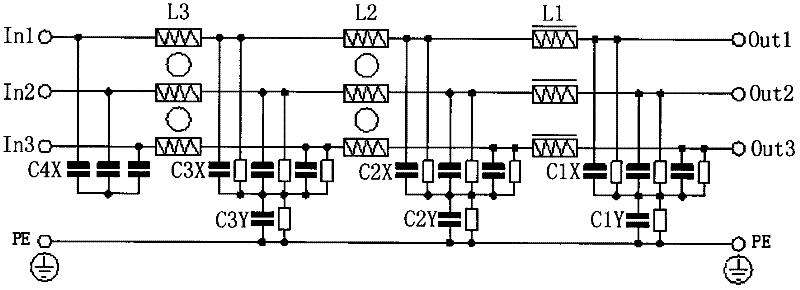

[0011] figure 1 It is the circuit diagram of the high-power EMI filter of the present invention.

[0012] See figure 1 , the high-power EMI filter provided by the present invention includes a three-phase current output load end and a three-phase current input end, wherein, between each phase current output load end and the input end, there are differential mode inductor L1, common mode inductor L2 and Common-mode inductor L3; the differential-mode inductor L1 is connected to the differential-mode capacitor C1X and common-mode capacitor C1Y to form a first-order filter; the common-mode inductor L2 is connected to the differential-mode capacitor C2X and common-mode capacitor C2Y to form a second-order filter filter; the common-mode inductance L3 is connected to the differential-mode capacitor C3X and the common-mode capacitor C3Y to form a third-order f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com