Diode clamped three-level high-voltage matrix converter and modulation method thereof

A diode-clamped, matrix converter technology, used in AC motor control, conversion of AC power input to AC power output, wind power generation, etc., can solve problems such as large switching loss, motor rotor winding insulation breakdown, and efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

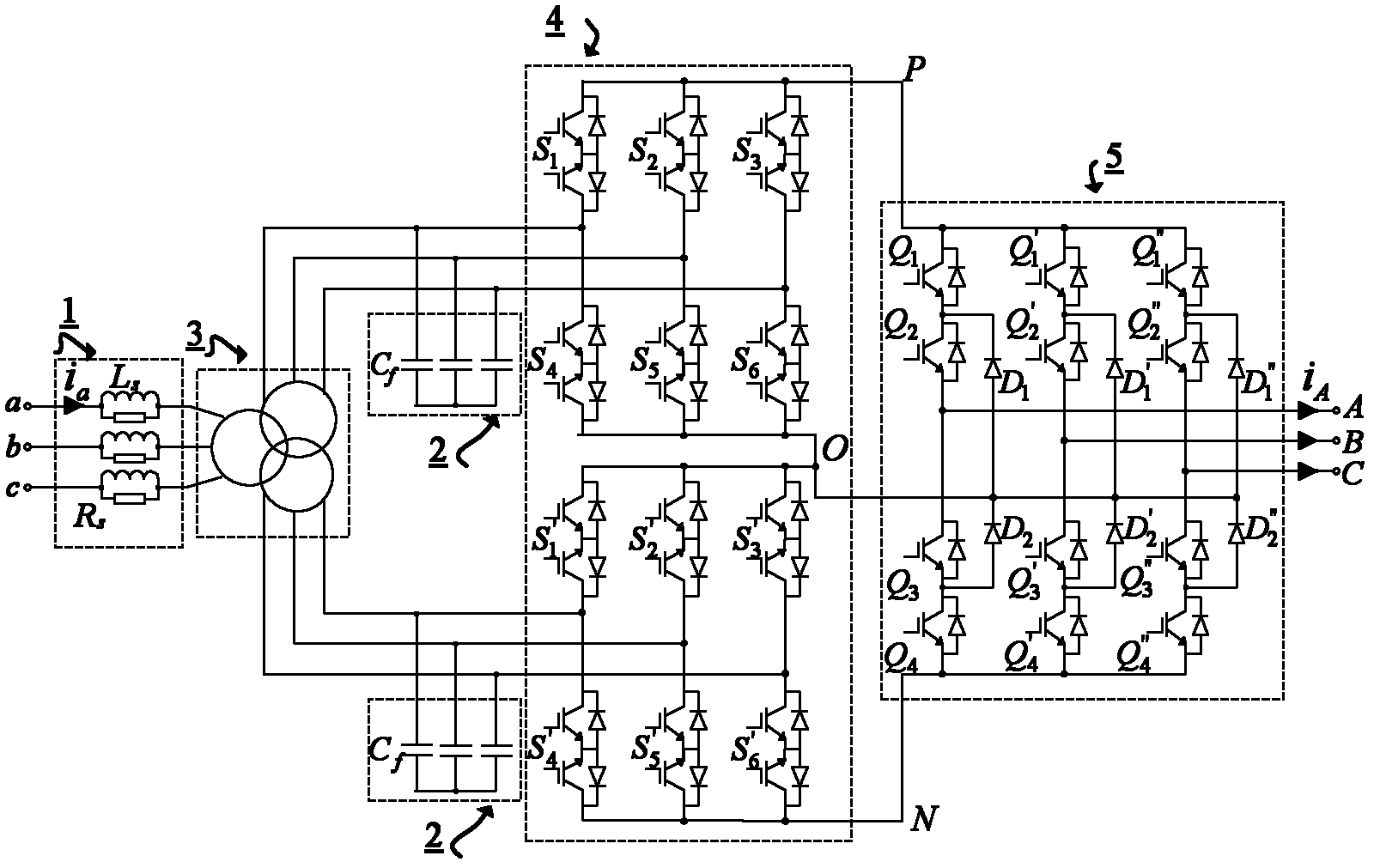

[0057] reference Image 6 The topology and control ideas of the present invention are described. Image 6 The main circuit includes filter reactance and damping resistance 1 , Filter capacitor 2 , Three-phase three-winding transformer 3 , High voltage rectifier 4 , Three-phase diode clamped three-level inverter 5 And drive circuit 8 A total of six parts, the control circuit consists of the sampling circuit 6 And controller 7 composition. Filter reactance and damping resistance 1 The left ends of a, b, and c are respectively connected to the three phases of the three-phase grid, and the right end is connected to the three-phase three-winding transformer 3 The original winding is connected. Three-phase three-winding transformer 3 Two sets of secondary windings and filter capacitors 2 Parallel connection, and then separately with the high voltage rectifier 4 The AC input sides of the two sets of three-phase matrix rectifiers are connected, and the configuration of the two secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com