Wind power generator having an internal coolant circuit

A wind turbine and internal cooling technology, applied in wind power generation, cooling/ventilation devices, electric components, etc., can solve problems such as failure, adverse effects of wind turbine operation, erosion of electrical breakdown strength of insulation layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention and further advantageous embodiments of the invention will be described in detail below with the aid of an exemplary embodiment shown in the drawings.

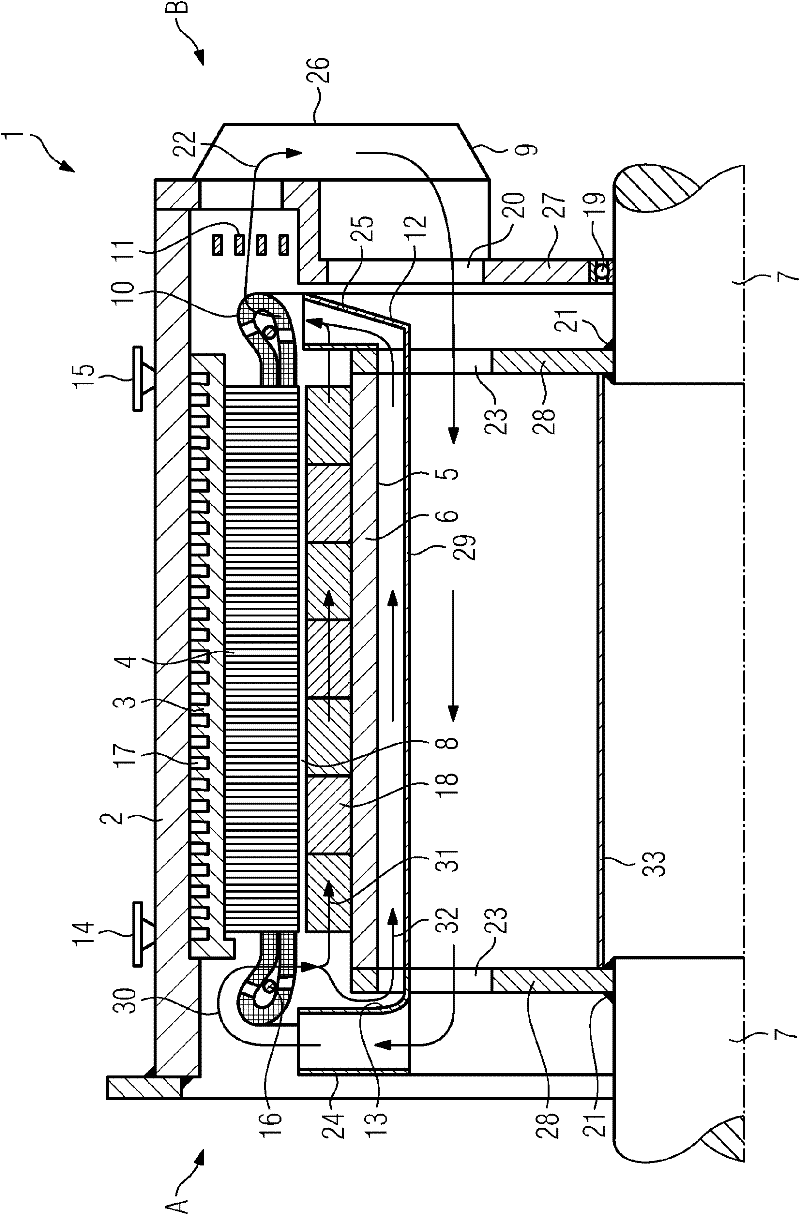

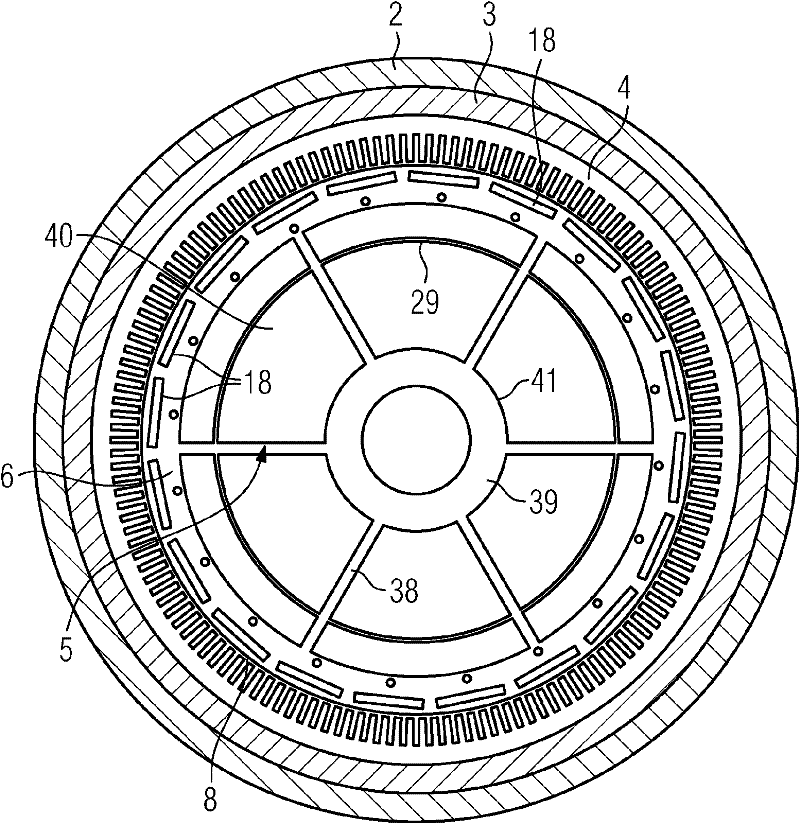

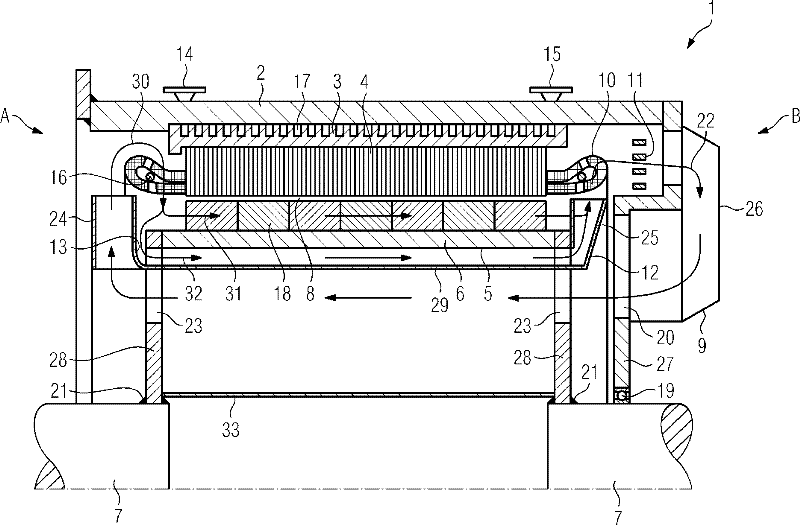

[0015] figure 1 It is a longitudinal sectional view of the wind power generator 1 including end A and end B, wherein end A faces the wind turbine of the wind power equipment which is not shown in detail in the figure. The mechanical coupling to the wind turbine is established directly via a shaft or at least one journal 7 or indirectly via a gear mechanism. The wind turbine 1 is accommodated in a housing 2 which has inlets and outlets 14 , 15 for supplying and discharging coolant to a cooling jacket 3 which is arranged between the housing 2 and the stator 4 . Losses are removed from the laminated core of the stator 4 via the cooling jacket 3 and the cooling medium flowing in the cooling channels 17 .

[0016] The end faces of the laminated cores of the stator 4 form the winding heads 10, which protrude a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com