Rotary abrasive flow polishing device for integral impeller type parts

A technology of integral impeller and polishing device, applied in the direction of grinding workpiece supports, can solve the problems of local over-polishing, low processing efficiency, difficult-to-process materials, etc., achieve uniform pressure field distribution, solve cleaning problems, and environmental protection of the processing environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

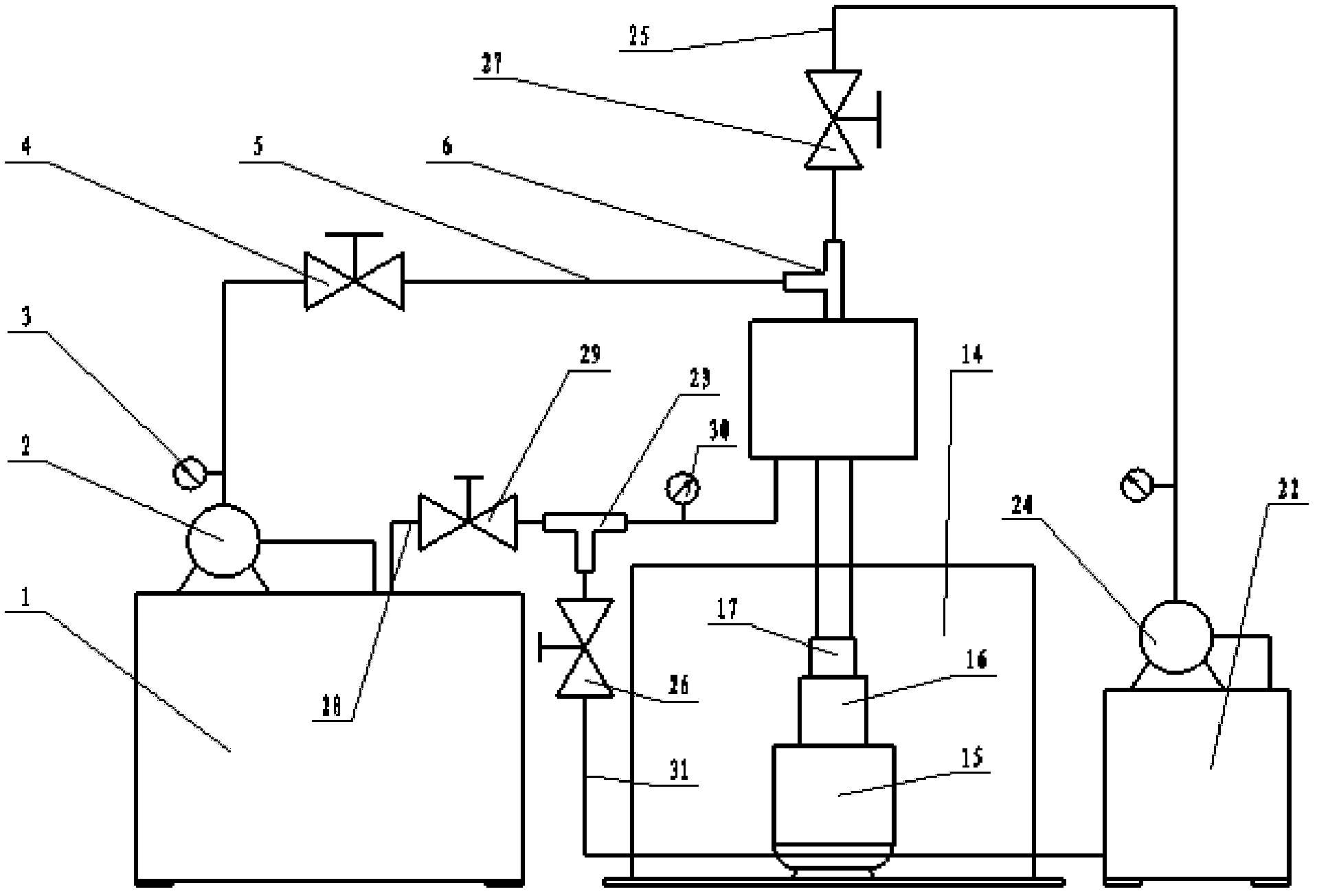

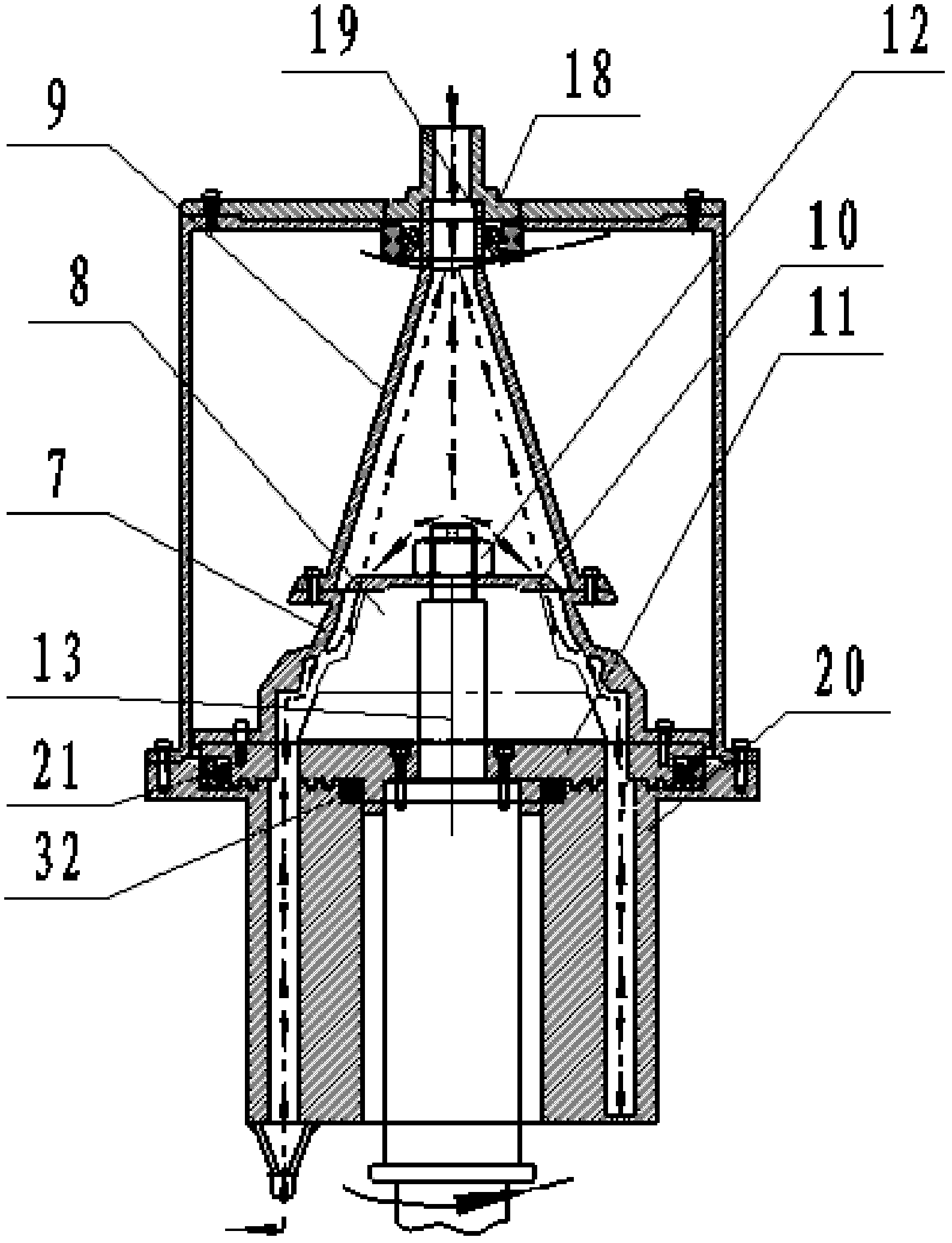

[0037] The following takes the integral radial flow titanium alloy impeller as an example, refer to the attached figure 1 , with figure 2 The implementation process of the rotary abrasive flow polishing device and method is described:

[0038] The integral radial flow titanium alloy impeller abrasive flow device includes the following structure:

[0039] Firstly, the main body 7 of the profiled jig cover 7 which is similar to the shape of the overall impeller curve is covered on the blades of the overall impeller, and is fixed integrally with the overall impeller 8 through the upper and lower jig covers 10 and 11 .

[0040] Secondly, the integral impeller 8, the fixture cover main body 7, and the upper and lower furniture covers 10, 11 are fixed on the machine tool spindle 13 by the round nut 12, and the machine tool spindle 13 is fixed on the workbench shaft seat 14, and the reducer is driven by the motor 15 16 is connected to the main shaft 8 through the reducer connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com