Venturi effect and a kind of LED heat dissipation device modified by synthetic jet

A technology of Venturi effect and heat dissipation device, which is applied to the cooling/heating device, lighting device, fixed lighting device and other directions of lighting devices, can solve the problems of limited heat dissipation capacity of profiles, can not meet the heat dissipation requirements, and is difficult to be popularized and used. Increase the processing difficulty, improve the jet intensity and energy utilization efficiency, and improve the effect of volume utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

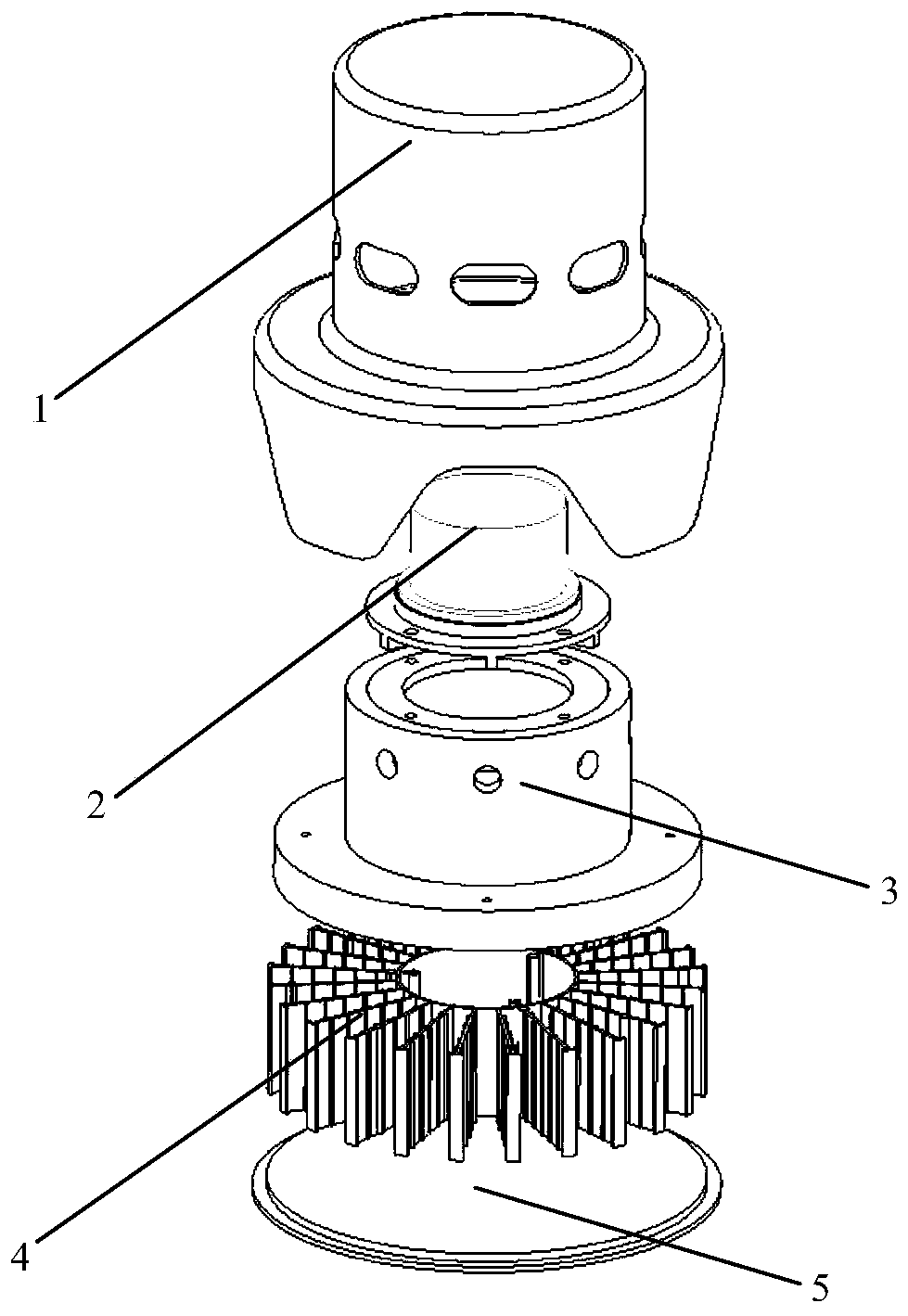

[0028] Such as figure 1 As shown, the present invention provides a Venturi effect and a modified synthetic jet device for an LED cooling device, including a housing 1, a synthetic jet actuator 2, fins 4, an LED substrate 5, and a Venturi tube 3. The fins 4. The Venturi tube 3 and the synthetic jet actuator 2 are fixed inside the cavity formed by the LED substrate 5 and the housing 1, so that the positions of the Venturi tube 3 and the fins 4 are relatively fixed, and the lower housing 207 and the Venturi tube 3 connection, the venturi tube 3 outlet is connected to the fin 4, and the housing 1 is fixed to the LED substrate 5 through the chute.

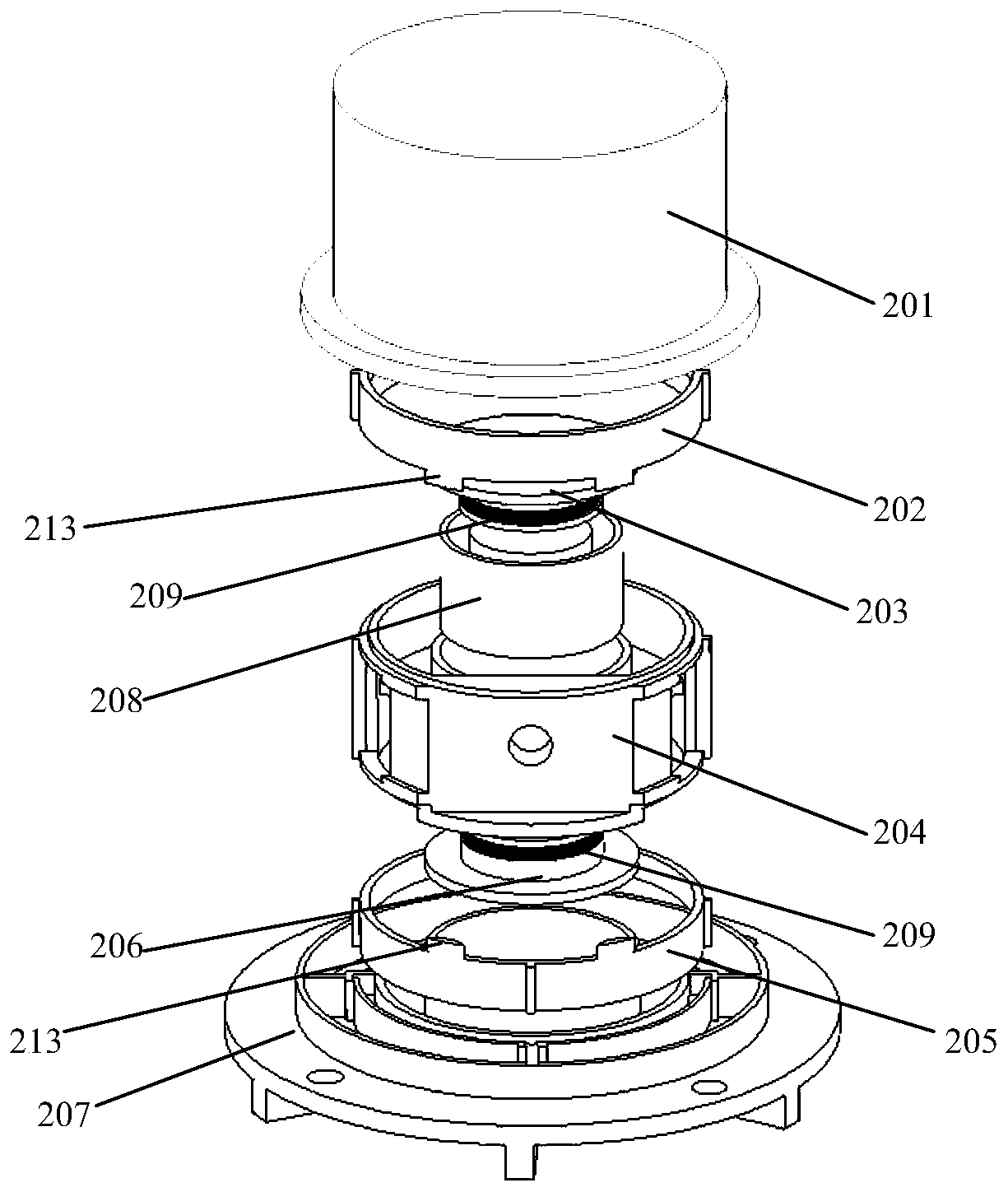

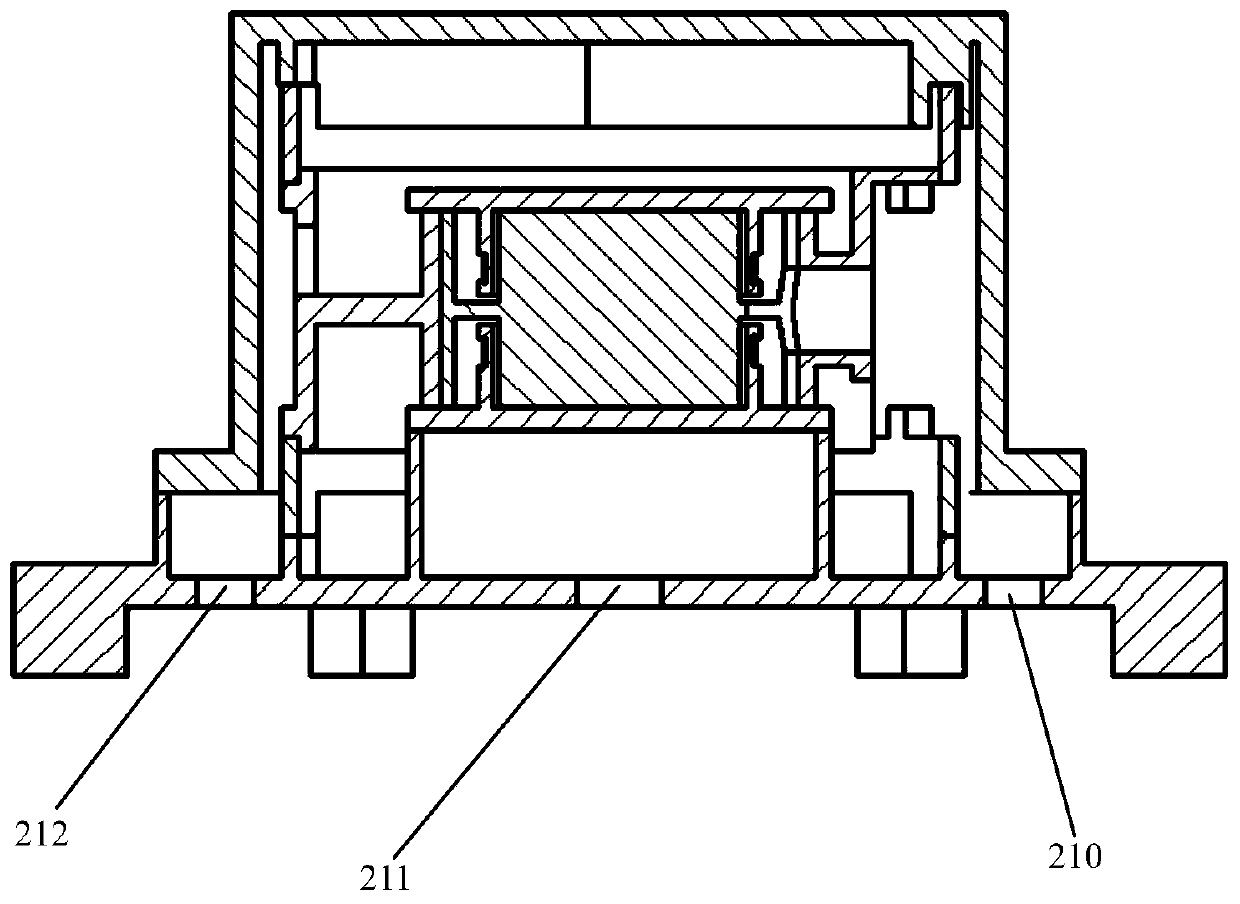

[0029] Such as Figure 2-3 As shown, the synthetic jet actuator 2 includes an upper casing 201, an upper diaphragm fixed support 202, an upper diaphragm 203, a permanent magnet fixed support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com