Fully sealed mold ultra-high vacuum die-casting and injection molding device and operation method

An ultra-high vacuum, fully-sealed technology, applied in the field of vacuum die-casting and injection molding devices, can solve the problems of clogging the vacuum pipeline, reducing the vacuum degree, and failing to reach ultra-high vacuum, and achieve the goal of improving quality, improving vacuum degree, and accelerating fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

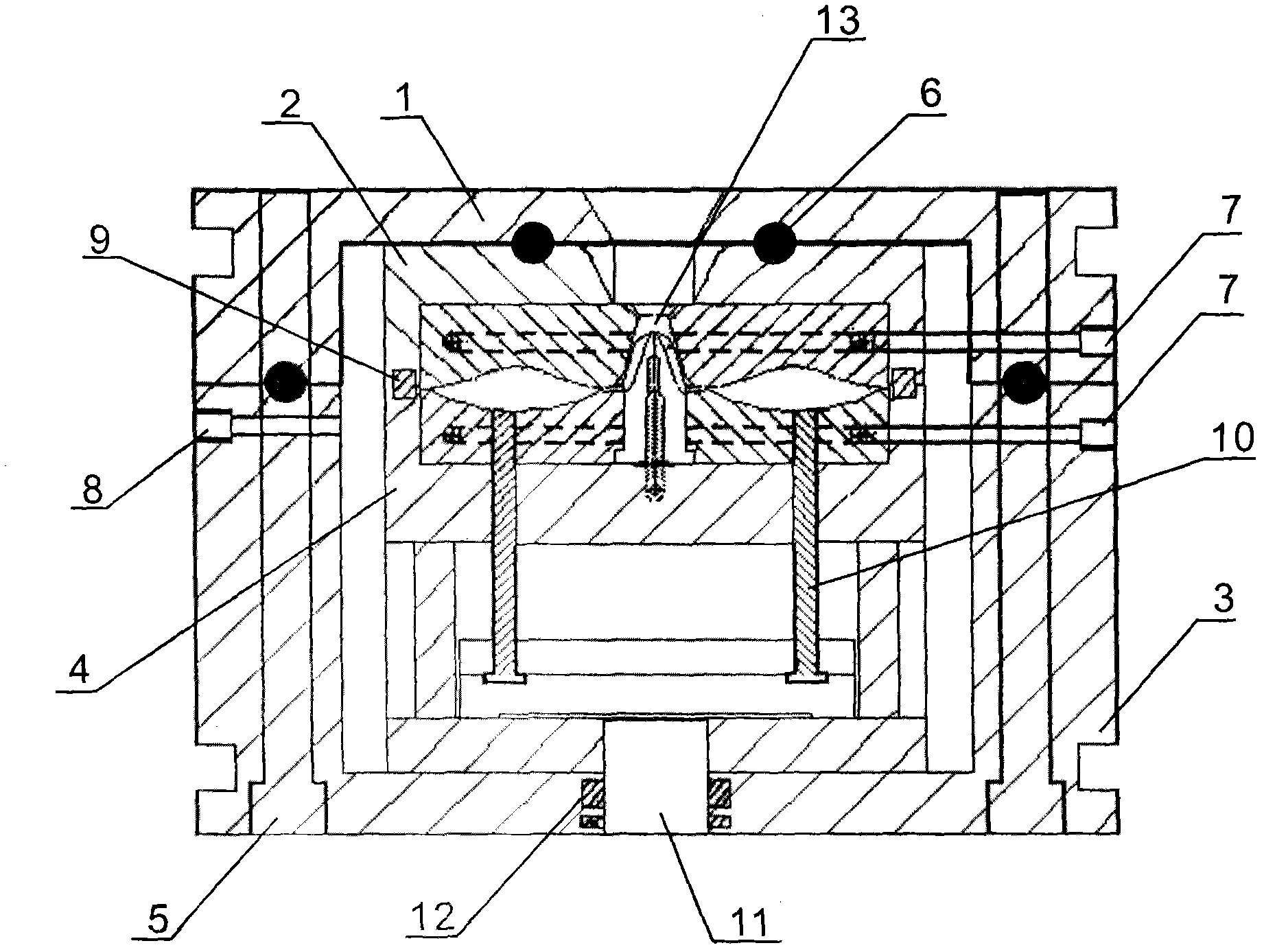

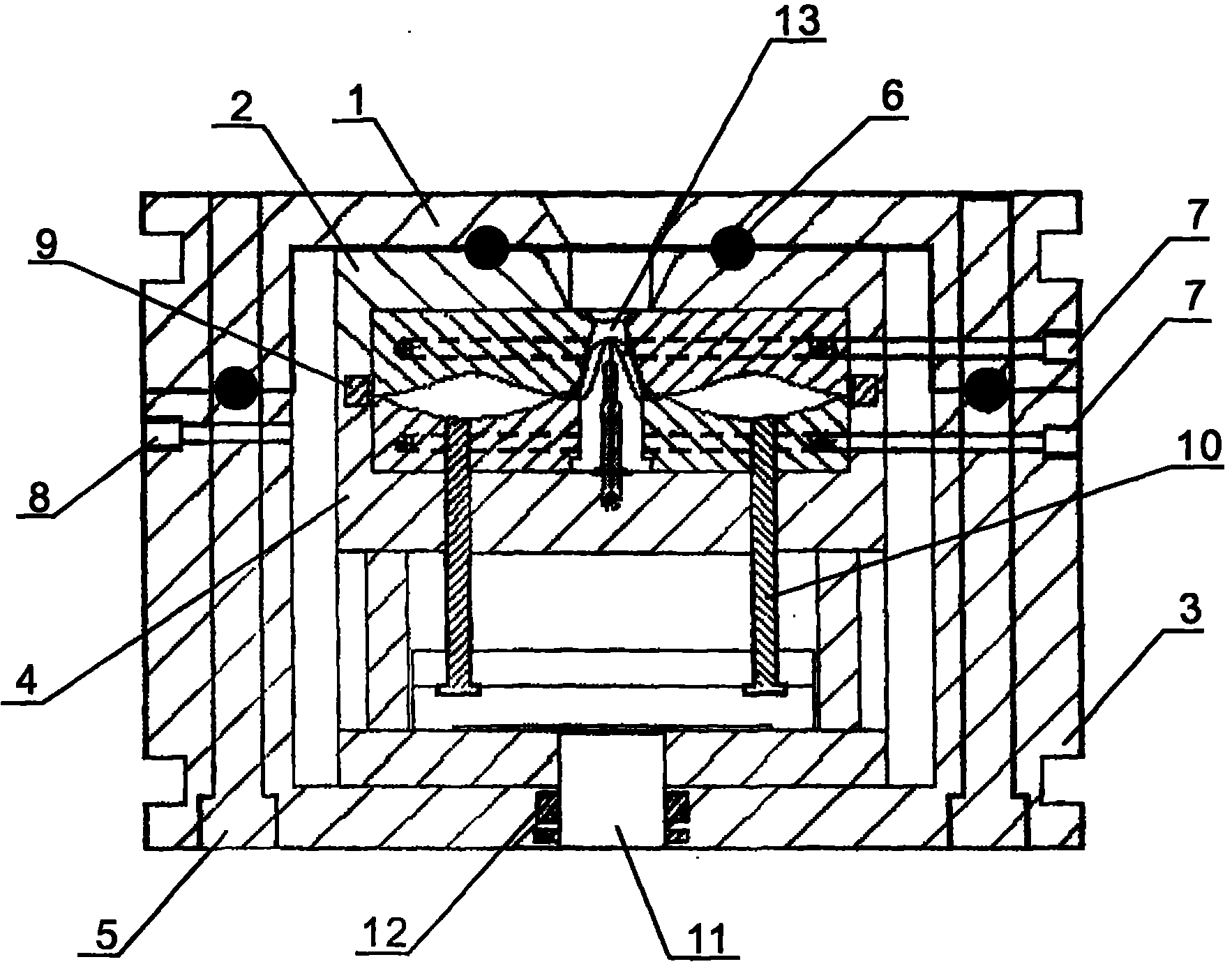

[0026] Device and operation method for car mold shell of ultra-high vacuum die-casting zinc alloy material using fully sealed mold

[0027] 1. A device that adopts a full-sealed mold ultra-high vacuum die-casting zinc alloy car mold shell, such as figure 1 Shown:

[0028] 1. Set up the mold sealing box:

[0029] A mold sealing box is arranged outside the mold in a common die-casting machine, and the mold sealing box includes a front fixed mold sealing box 1 and a rear movable mold sealing box 3 . The front fixed mold sealing box 1 is arranged on the outside of the front fixed mold 2, and the rear moving mold sealing box 3 is arranged on the outside of the rear moving mold 4. A casting thimble 10 is provided in the middle of the rear movable mold 4 and the rear movable mold sealing box 3 , the bottom edge of the rear movable mold sealing box 3 is provided with an ejector rod 11 , and the periphery of the ejector rod 11 is provided with two sealing rings 12 . A vacuum tube 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com