Servo driving type die-cast machine

A servo-driven, die-casting machine technology, applied in the field of die-casting machines, can solve the problems of high energy consumption, poor sensitivity, large waste, etc., and achieve the effects of good energy saving, sensitive response, and simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041] Such as Figure 3-8 shown.

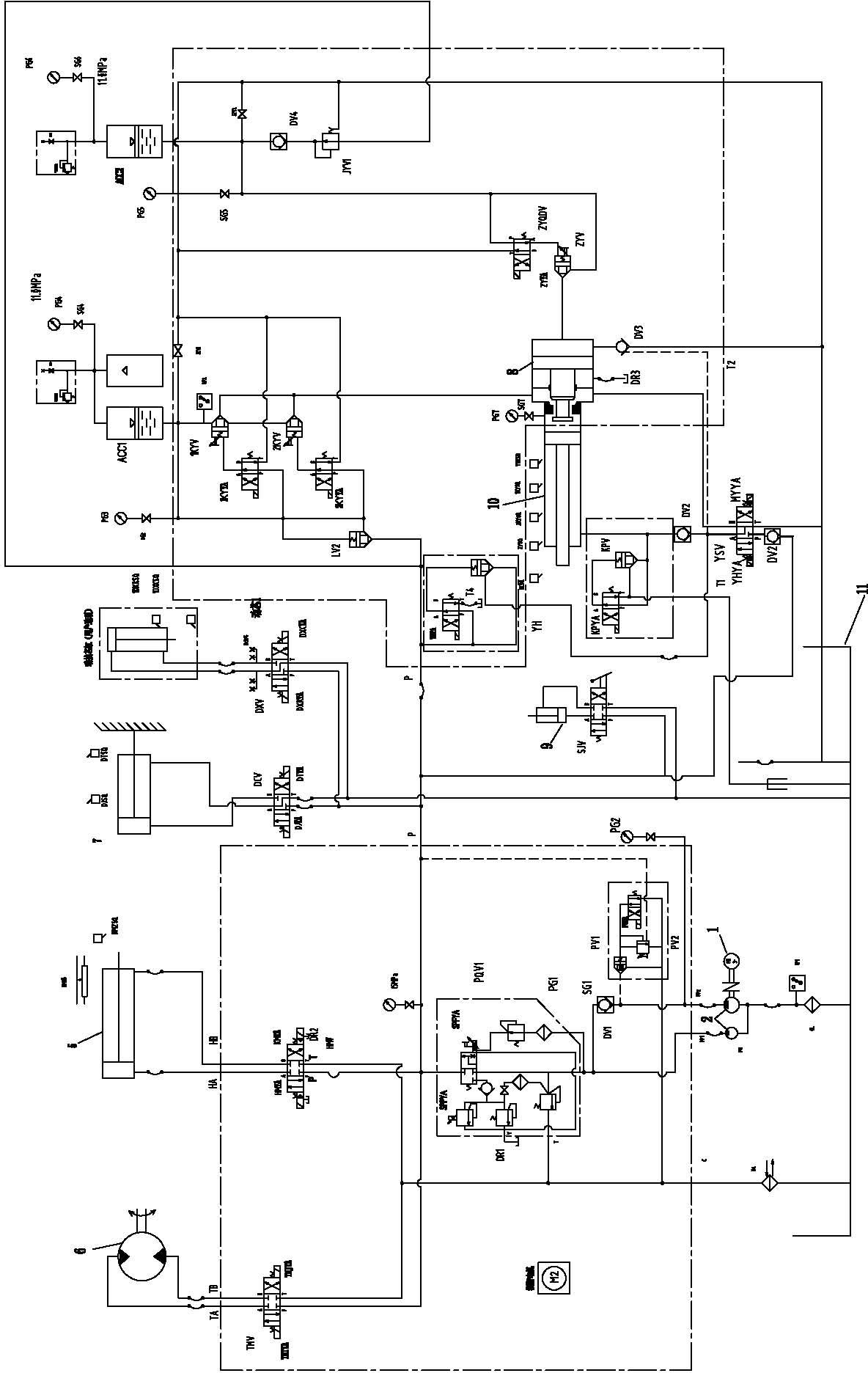

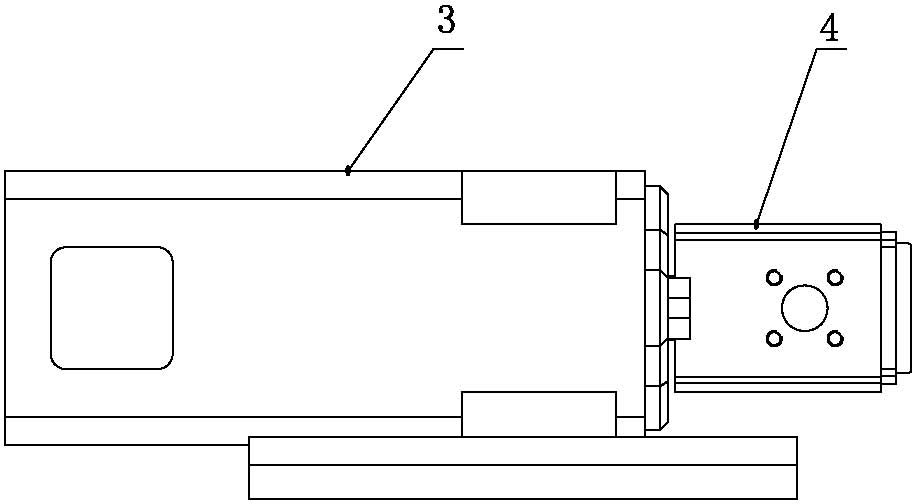

[0042] A servo-driven die-casting machine, its basic mechanical structure is basically the same as the existing die-casting machine, the key of the present invention is its power system, namely the servo drive system, and the parts that are prone to failure during actual production and use, such as the injection rod 203. The structure and driving mode of the ejector push plate 302 and the mold adjustment gear 403 have been improved. The details are as follows:

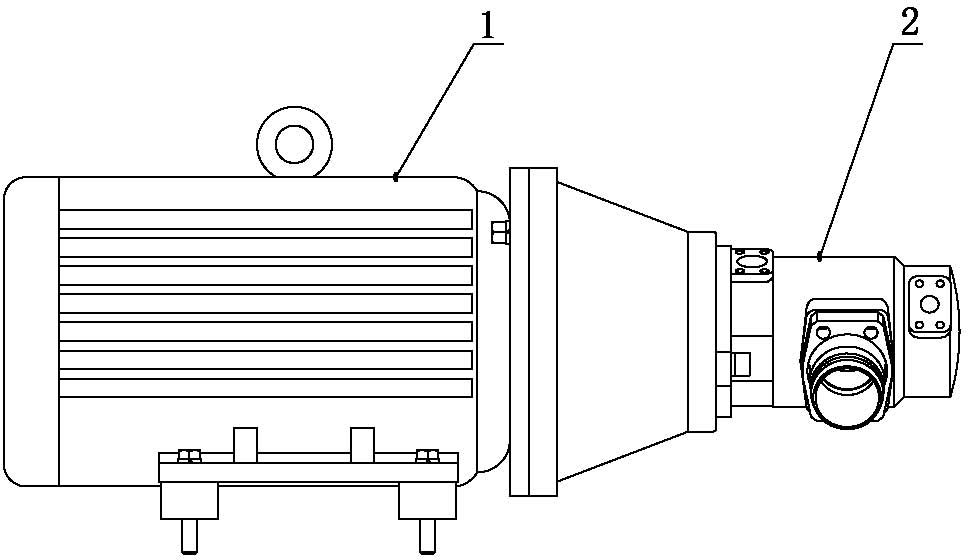

[0043] A servo-driven die-casting machine, its power part consists of a servo motor 3 and an oil pump 4, such as image 3 As shown, the oil pump 4 can be one of a gear pump, a plunger pump or a screw pump, the output of the oil pump 4 is connected to the input end of the hydraulic actuator, and pressure and flow sensors are installed in the hydraulic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com