Subcritical hydrothermal equipment for sludge treatment

A subcritical water and sludge treatment technology, applied in the field of hydrothermal equipment and subcritical hydrothermal equipment, to achieve the effect of solving blockage, convenient operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

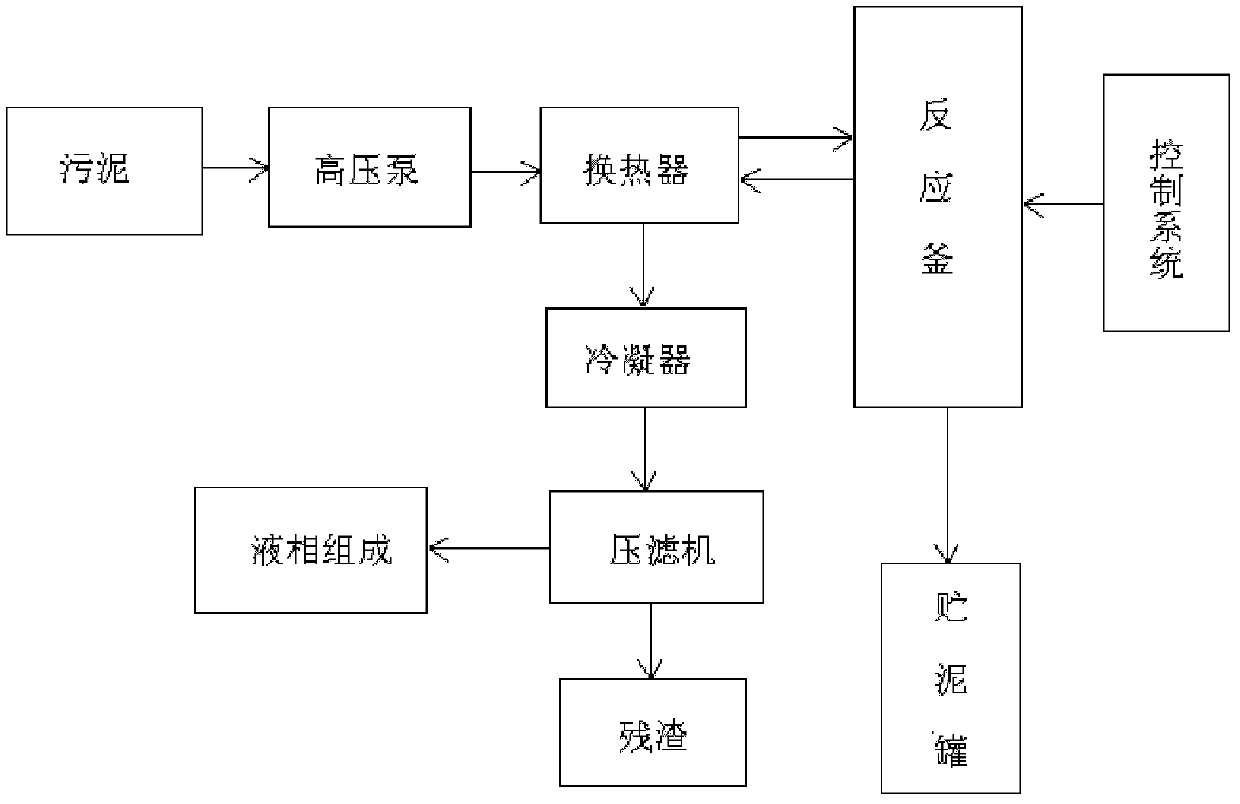

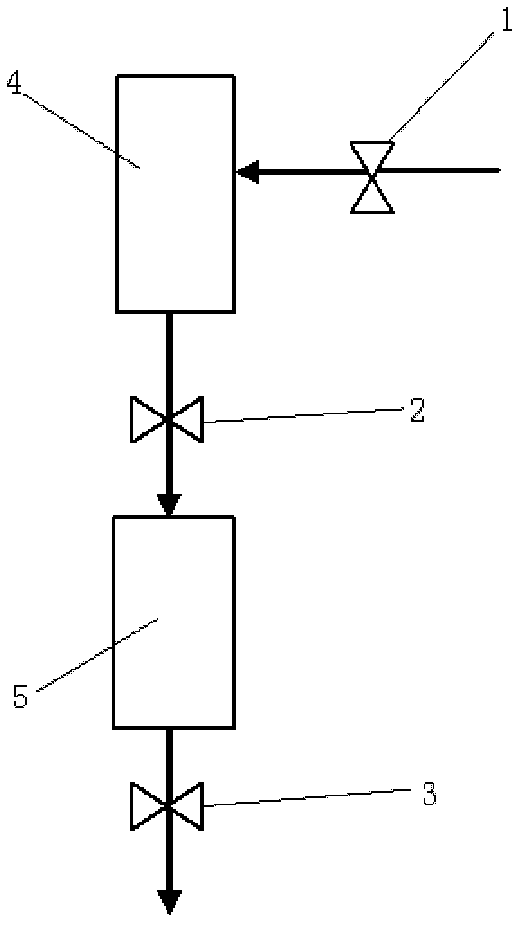

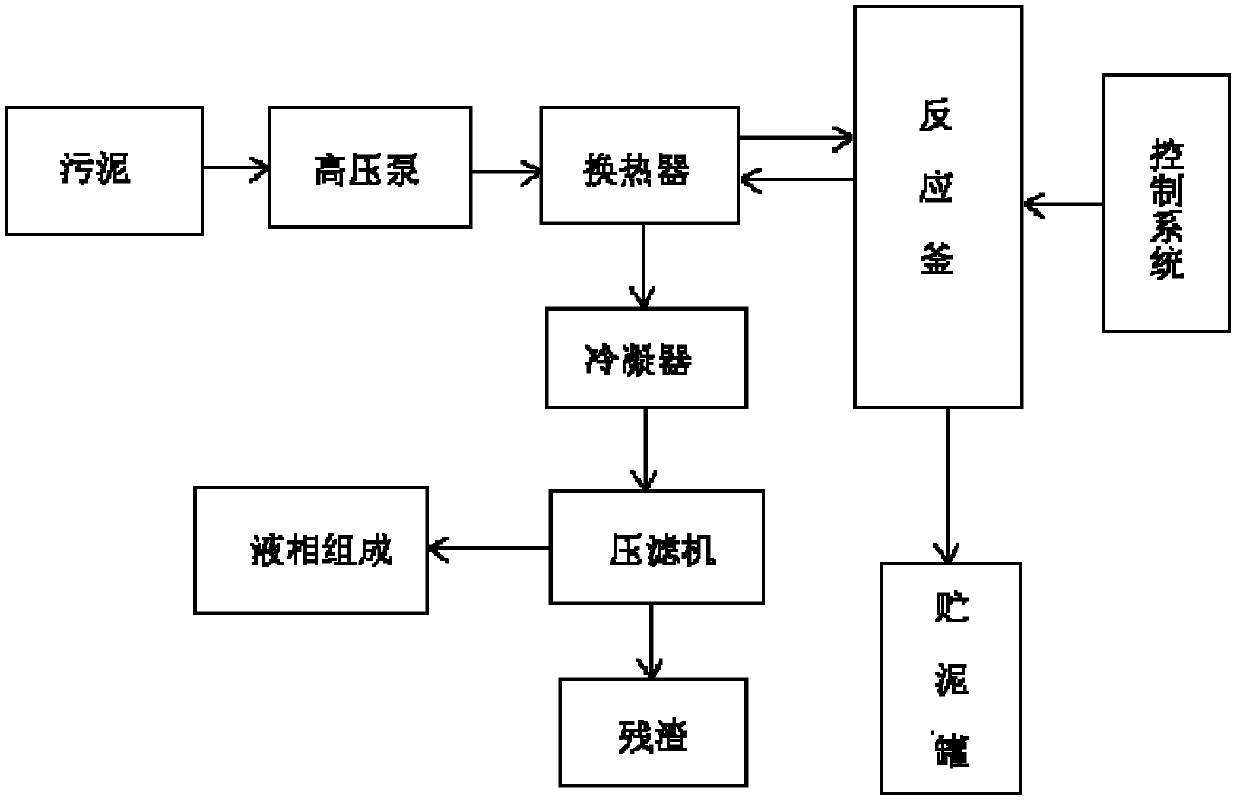

[0021] Such as figure 1 , figure 2 As shown, a control valve is provided at the inlet and outlet of the high-temperature and high-pressure reactor 4, and the lower outlet valve is connected to a mud storage tank 5. The sludge is discharged from the bottom of the mud storage tank 5 through sedimentation and separation, and water vapor is discharged from the top of the mud storage tank 5. flow out. The system feeds materials when the reaction kettle 4 is under low pressure. After a certain amount of feeding is completed, the feed valve 1 is closed, and the pressure of the reaction kettle 4 rises to a subcritical hydrothermal state, or even a supercritical state. The bottom of the reactor 4 is provided with a control valve, which is controlled by the control system. Then open the discharge valve 2 at the bottom of the reactor to allow the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com