Rotating shaft having reverse oblique interleaving mutual cleaning-type rotating discs for sludge drying machine

A sludge drying and mutual cleaning technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, can solve the problems of affecting the drying rate and difficult leaf stripping, so as to improve the processing capacity, speed up the evaporation speed, and improve the heat conduction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Referring to the accompanying drawings, the present invention will be described in detail in conjunction with the embodiments.

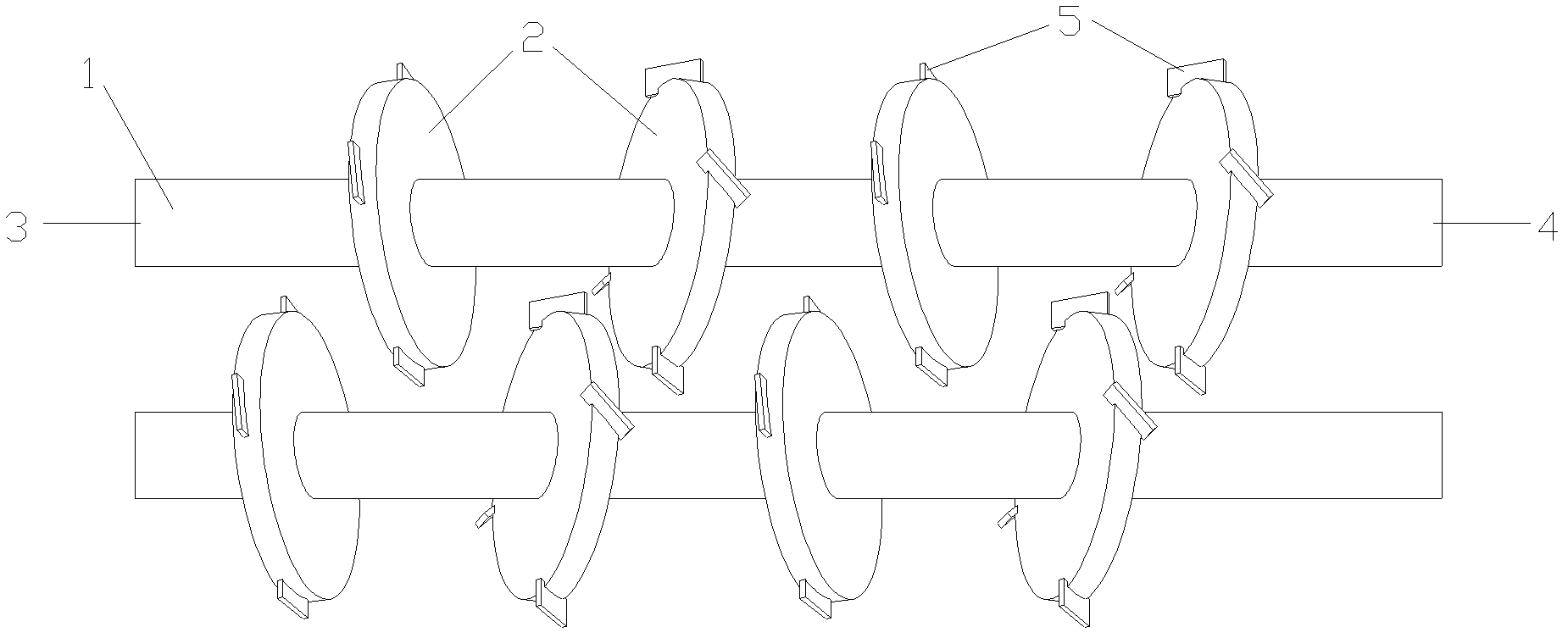

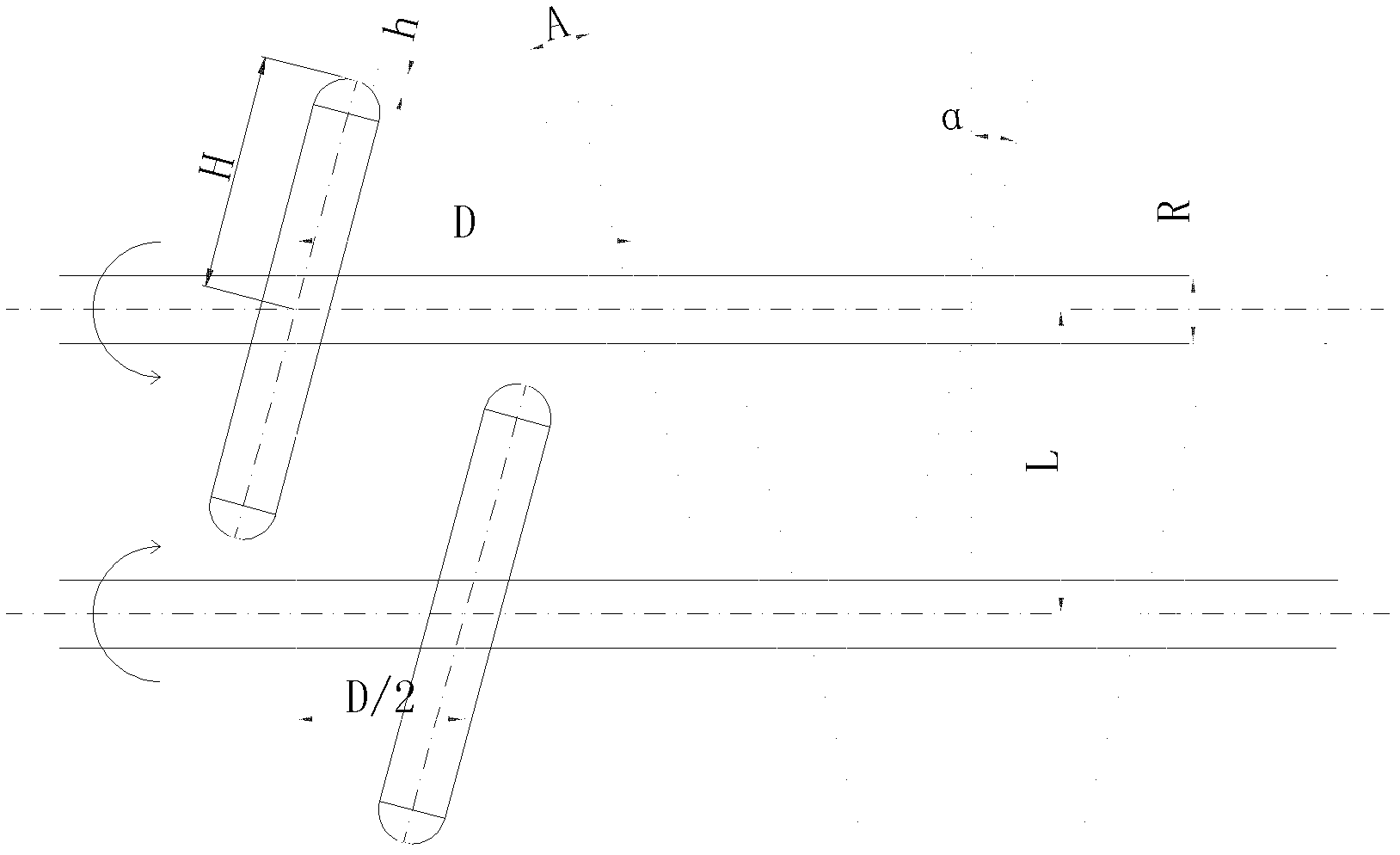

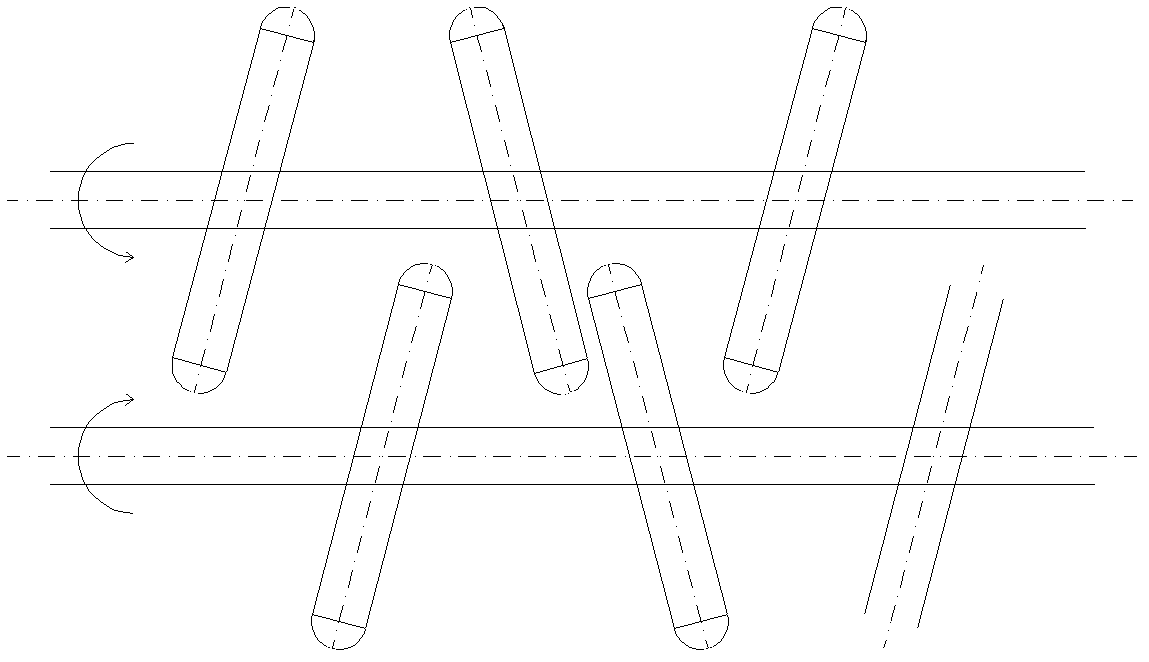

[0030] This embodiment provides a rotating shaft with reverse inclined staggered mutual cleaning turntables for sludge dryer, its structure is as follows figure 1 shown. It includes: a cylindrical rotating shaft 1 and several equidistantly distributed reversely inclined turntables 2 installed on the rotating shaft 1; The thermal medium inlet 3 and the thermal medium outlet 4 can be installed at both ends respectively, or the pipe-in-pipe form can be adopted, and the thermal medium inlet and outlet can be set at the same end; the reverse inclined turntable 2 adopts a disc-shaped hollow design, The connection with the hollow shaft 1 is internally communicated, and the thermal medium can flow freely inside the hollow shaft 1 and the turntable 2; the turntable 2 is inclined to the vertical section of the hollow shaft 1, and the inclination direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com