Online film coating device for float glass

A technology of coating device and float glass, which is applied in the field of online coating device for float glass, can solve the problems of increased installation cost of the coating device, achieve the effects of saving coating raw materials, facilitating smooth inflow, and improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

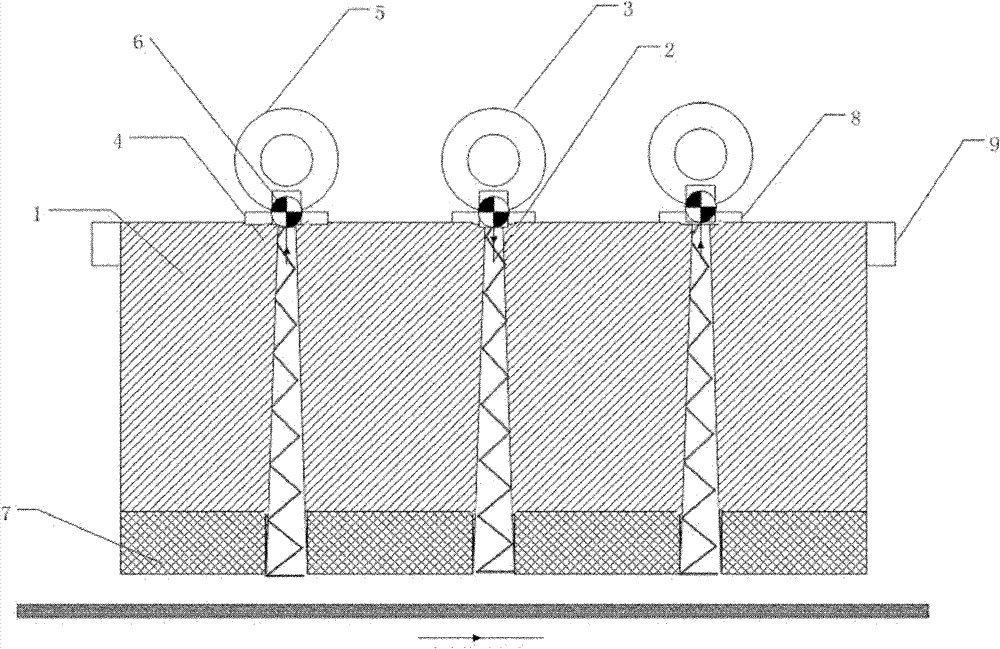

[0020] Such as figure 1 Shown, a kind of float glass online coating device comprises suspension beam 9, a coater body 1 installed on the suspension beam 9, graphite plate 7 arranged on the bottom surface of the body 1, and an air intake unit and two rows Air unit, the two exhaust units are arranged on both sides of the air intake unit, and the whole coating device is assembled in the tin bath on the float glass production line through the suspension beam 9.

[0021] Each air intake unit comprises a conical air intake pipe 2 with a small upper part and a larger lower part that runs through the graphite plate 7 and the body 1 simultaneously and an air intake device 3 positioned at the top of the air intake pipe 2, the air intake device 3 is connected with the air intake pipe 2 is provided with a flow regulating valve 6, and the intake pipe 2 is provided with a spiral groove. And a sealing plate 8 is installed at the joint between the air intake pipe 2 and the upper surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com