Natural environment-friendly plant gloss oil

A natural environmental protection, natural plant technology, applied in the direction of coating, etc., can solve environmental hazards and other problems, and achieve the effect of high environmental protection index, good scratch resistance and excellent hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

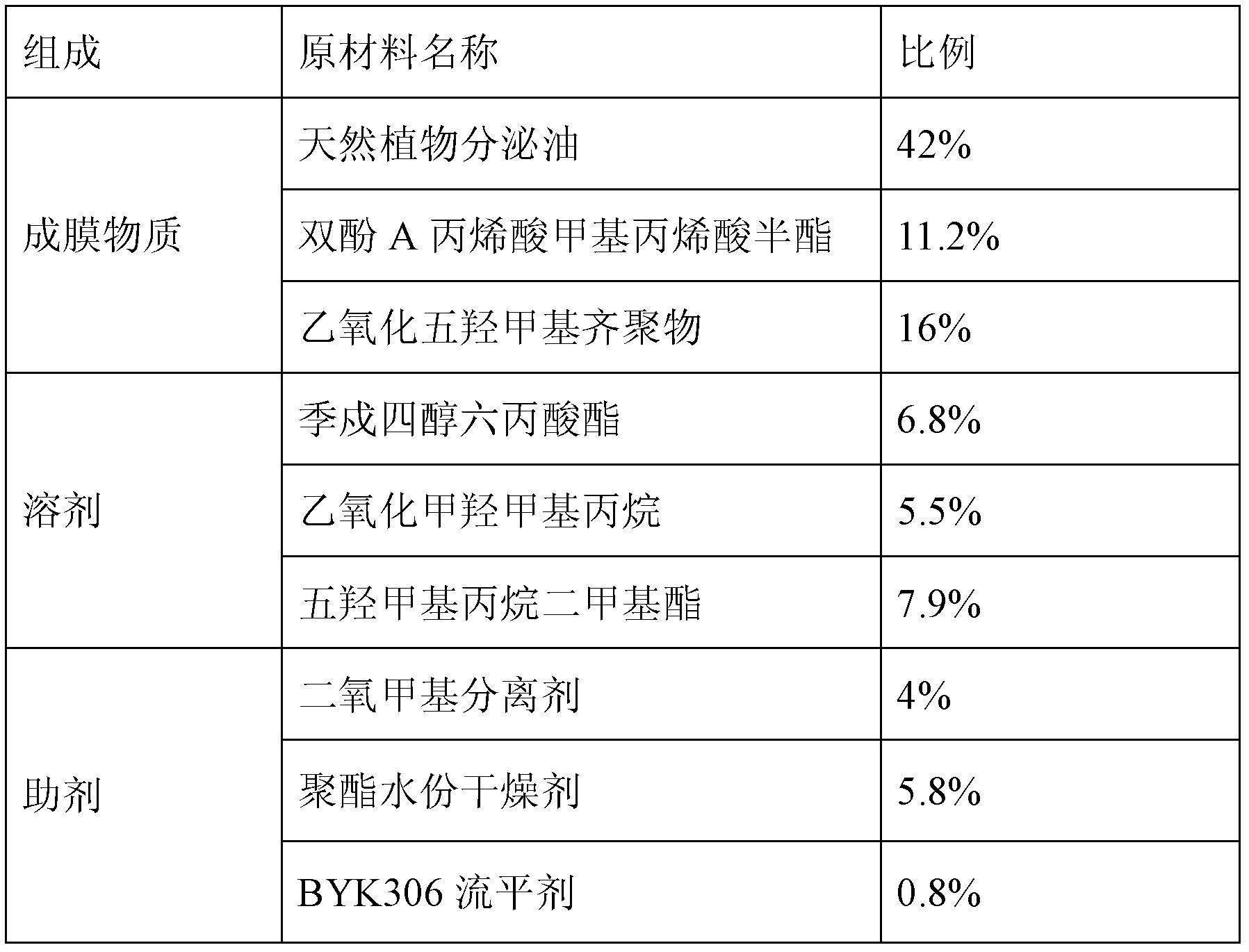

[0021] The component weight ratio of natural environment-friendly vegetable varnish is shown in Table 1. In the case of the weight component ratio in Table 1, the adhesion and hardness of natural environment-friendly vegetable varnish are tested.

[0022] Table 1

[0023]

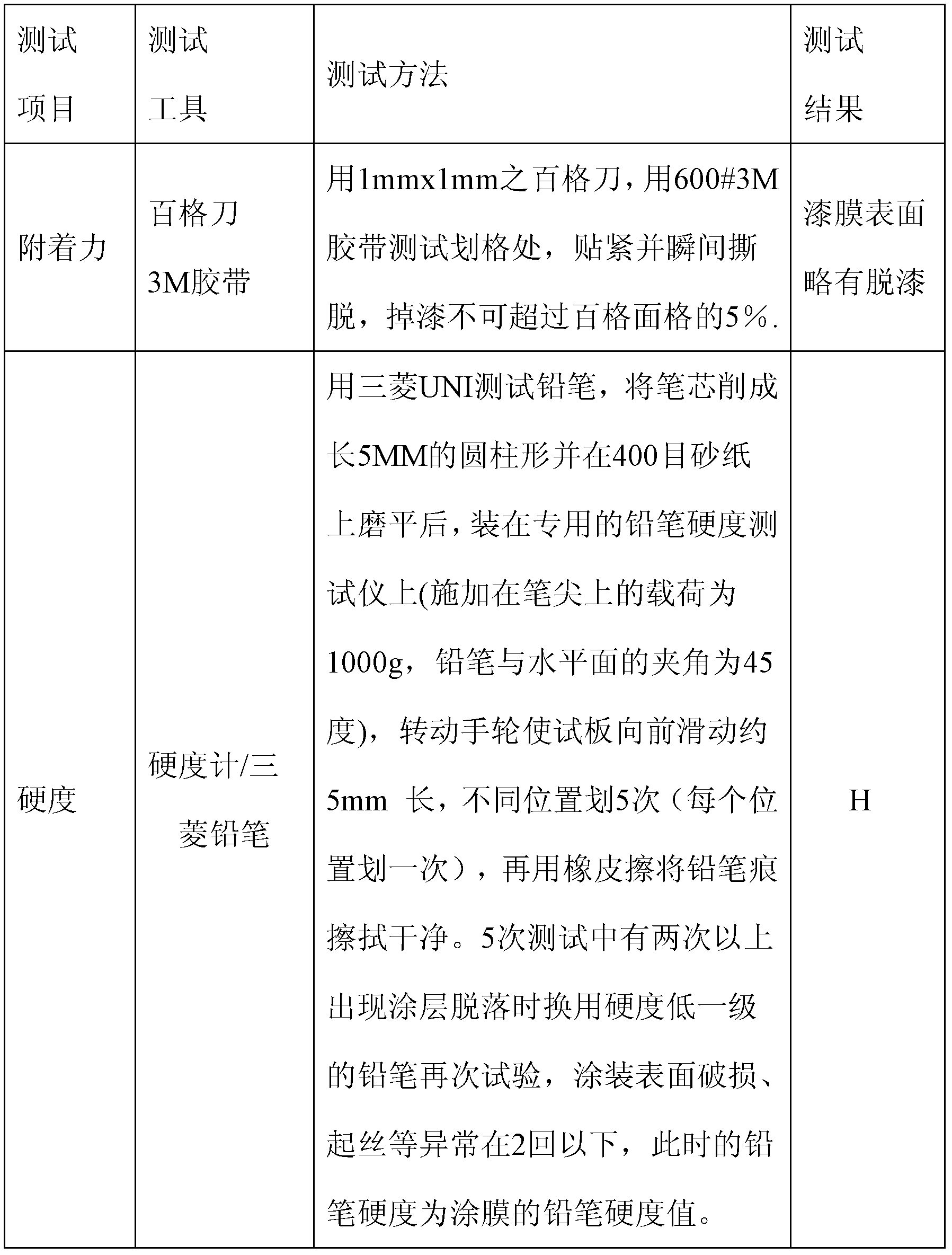

[0024] Under the weight ratio of the natural environment-friendly vegetable varnish components in Table 1, the results of testing adhesion and hardness are shown in Table 2.

[0025] Table 2

[0026]

[0027] As shown in table 1 and table 2, the weight ratio of natural plant secretion oil is 40.5%, the weight ratio of ethoxylated pentamylol oligomer is 17.5%, and the weight ratio of dioxymethyl separating agent is 4.0%, When the weight ratio of the polyester water desiccant is 5.8%, the experimental results show that the surface of the paint film has a slight paint peeling, and the hardness is H.

Embodiment 2

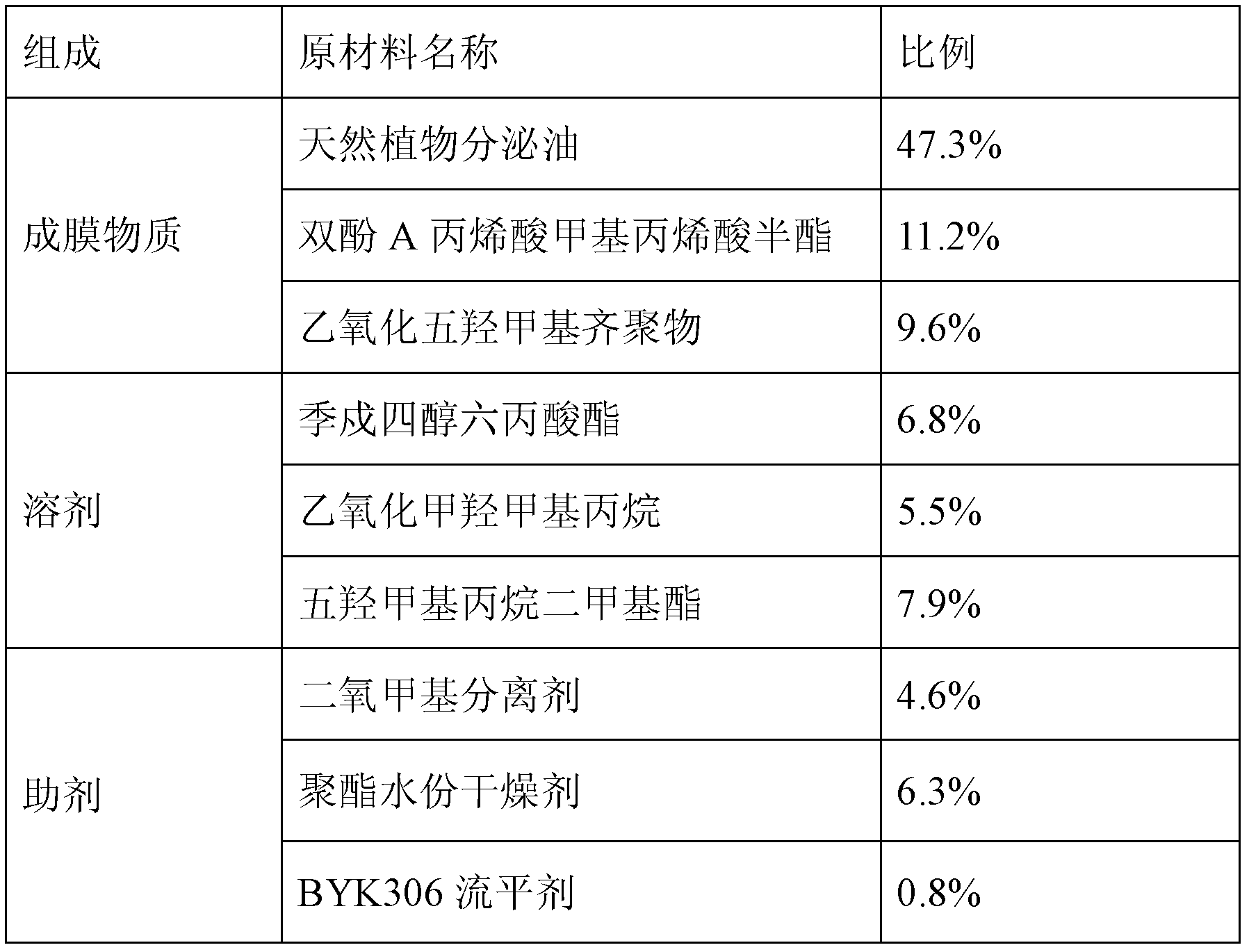

[0029] The component weight ratio of natural environment-friendly vegetable varnish is shown in Table 3. In the case of the weight component ratio of Table 3, the adhesion and hardness of natural environment-friendly vegetable varnish are tested.

[0030] table 3

[0031]

[0032] Under the weight ratio of the natural environment-friendly vegetable varnish in Table 3, the results of testing the adhesion and hardness of the natural environment-friendly vegetable varnish are shown in Table 4;

[0033] Table 4

[0034]

[0035]

[0036] As shown in table 3 and table 4, the weight ratio of natural plant secretion oil is 47.3%, the weight ratio of ethoxylated pentamylol oligomer is 9.6%, and the weight ratio of dioxymethyl separating agent is 4.6%, When the weight ratio of the polyester moisture desiccant is 6.3%, the experimental results show that there is no paint stripping on the surface of the paint film, and the hardness of the paint film is 2H.

Embodiment 3

[0038] The component weight ratio of natural environment-friendly vegetable varnish is shown in Table 5. In the case of the weight component ratio in Table 5, the adhesion and hardness of natural environment-friendly vegetable varnish are tested.

[0039] table 5

[0040]

[0041]

[0042] Under the weight ratio of the natural environment-friendly vegetable varnish in Table 5, the results of testing the adhesion and hardness of the natural environment-friendly vegetable varnish are shown in Table 6;

[0043] Table 6

[0044]

[0045]

[0046] As shown in table 5 and table 6, the weight ratio of natural plant secretion oil is 51.3%, the weight ratio of ethoxylated pentamylol oligomer is 5.6%, and the weight ratio of dioxymethyl separating agent is 5.2%, When the weight ratio of the polyester water desiccant is 6.8%, the experimental results show that the surface of the paint film has slight paint peeling and hardness H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com