Local heat treatment method of thick-wall P92 pipeline in field condition

Through a combination of experiments and finite element analysis, the local heat treatment formula and process of P92 steel pipes were formulated, which solved the problem of uncertain heating width and insulation width under on-site working conditions, achieved stress relief and temperature difference control at the welded joints, and ensured Safe operation of pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, the P92 main steam pipe with ID538 (inner diameter) × 94.5 (wall thickness) mm is used for welding according to the P92 steel welding process, and a monitoring thermocouple is installed on the inner wall of the pipe before welding.

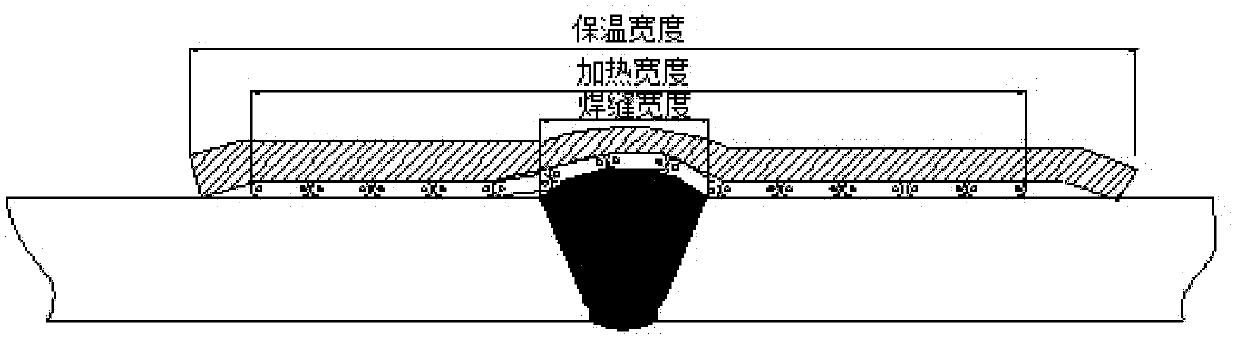

[0026] Calculate the width of the heating zone HB=1230mm, the width of the heat preservation zone GCB=1950mm, customize the heater and insulation cotton specifications (ie length) according to the calculation data, and choose the WDK-6360 flexible ceramic resistance heater.

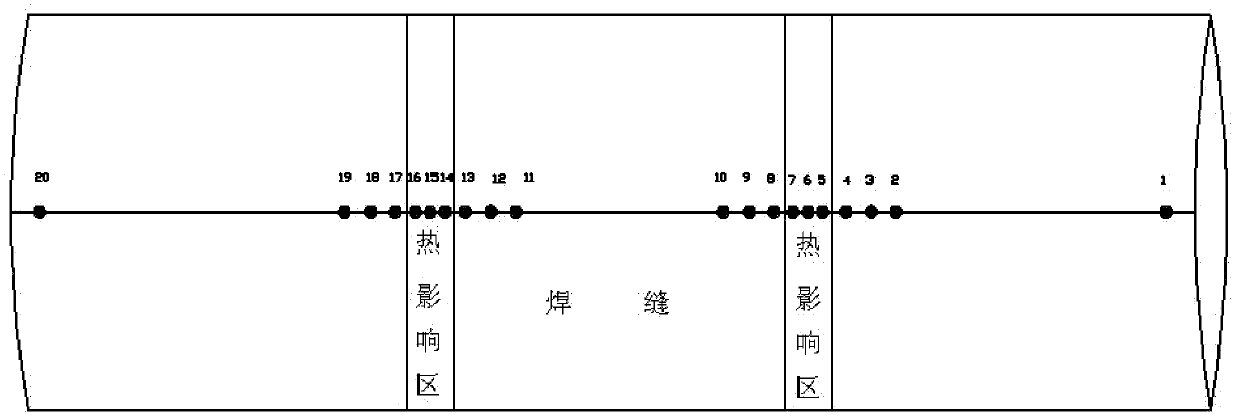

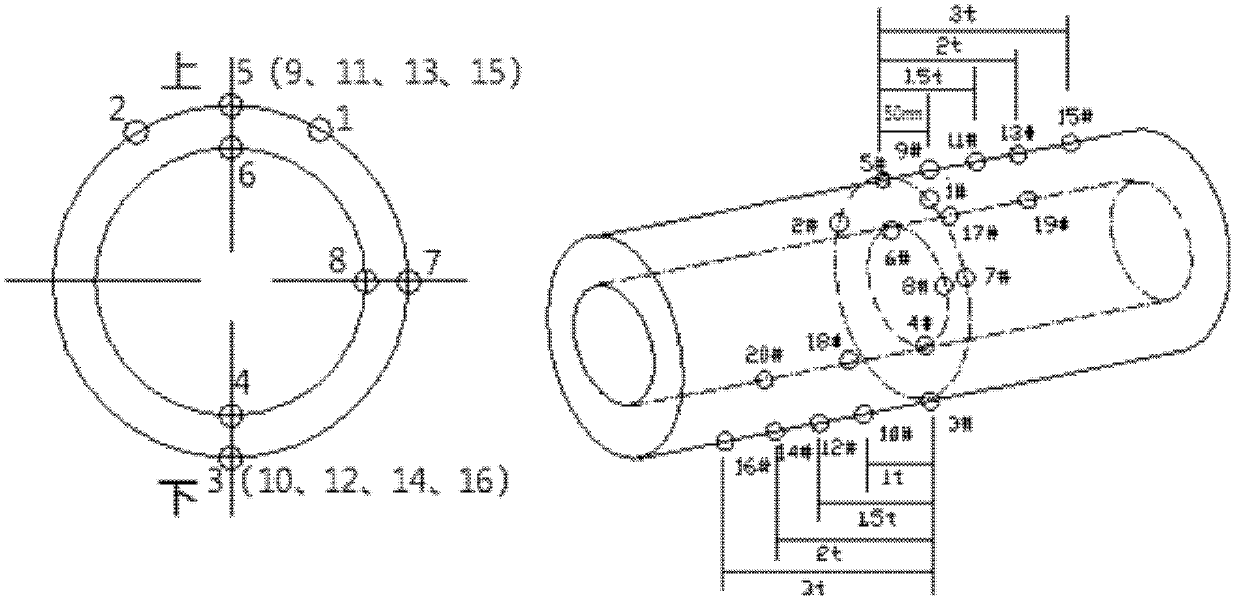

[0027] The X-ray method is used to test the residual stress at different distances from the center of the weld. Considering the distribution characteristics of the welding residual stress of the pipe joint, the interval between the test points in the weld area is 3mm (3 points close to the heat-affected zone), and the heat-affected The distance between the three test points in the area is 1.5mm, the distance between the first three points of the base metal is 3mm...

Embodiment 2

[0037] The P92 main steam pipe with ID538×91mm is used for welding according to the P92 steel welding process, and a monitoring thermocouple is installed on the inner wall of the pipe before welding.

[0038] Calculate the width of the heating zone HB=1167mm, the width of the heat preservation zone GCB=1859mm, customize the specifications of the heater and insulation cotton according to the calculation data.

[0039] Local heat treatment of the steel pipe: when the P92 pipe is naturally and slowly cooled (that is, cooled at room temperature in the air) to 150°C, install a corresponding heating device, heat preservation device, and arrange a thermocouple outside the P92 pipe according to the calculation results. When the temperature drops to 100 ℃, turn on the electricity to heat, keep the temperature at 100℃ for 2 hours; heat at 150℃ / h to 300℃, after the temperature reaches 300℃, raise the temperature to 765℃ at 80℃ / h, and keep the temperature for 8 hours. Control the cooling ...

Embodiment 3

[0047] The P92 main steam pipe with ID550×80mm is used for welding according to the P92 steel welding process, and a monitoring thermocouple is installed on the inner wall of the pipe before welding.

[0048] Calculate the width of the heating zone HB=944mm, the width of the heat preservation zone GCB=1548mm, and customize the specifications of the heater and heat preservation cotton according to the calculated data.

[0049] Local heat treatment of the steel pipe: when the P92 pipe is naturally and slowly cooled to 130°C, install the corresponding heating device, heat preservation device and thermocouple outside the P92 pipe according to the calculation results. It is kept at a constant temperature of 90°C for 2 hours; heated at 150°C / h to 300°C, and when the temperature reaches 300°C, it is heated at 80°C / h to 765°C, and the holding time is 8 hours. Control the cooling rate from 100°C / h to 300°C, turn off the power, cool slowly to room temperature, and remove the heater.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com