Non-quenched and tempered low-crack sensitivity steel plate with excellent low-temperature toughness, and production method thereof

A low-temperature toughness, non-quenched and tempered technology, applied in the field of low-alloy high-strength steel manufacturing, can solve problems such as unstable performance, affecting yield, and high load on the rolling mill, and achieve low welding crack sensitivity, excellent comprehensive performance, and excellent low-temperature toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

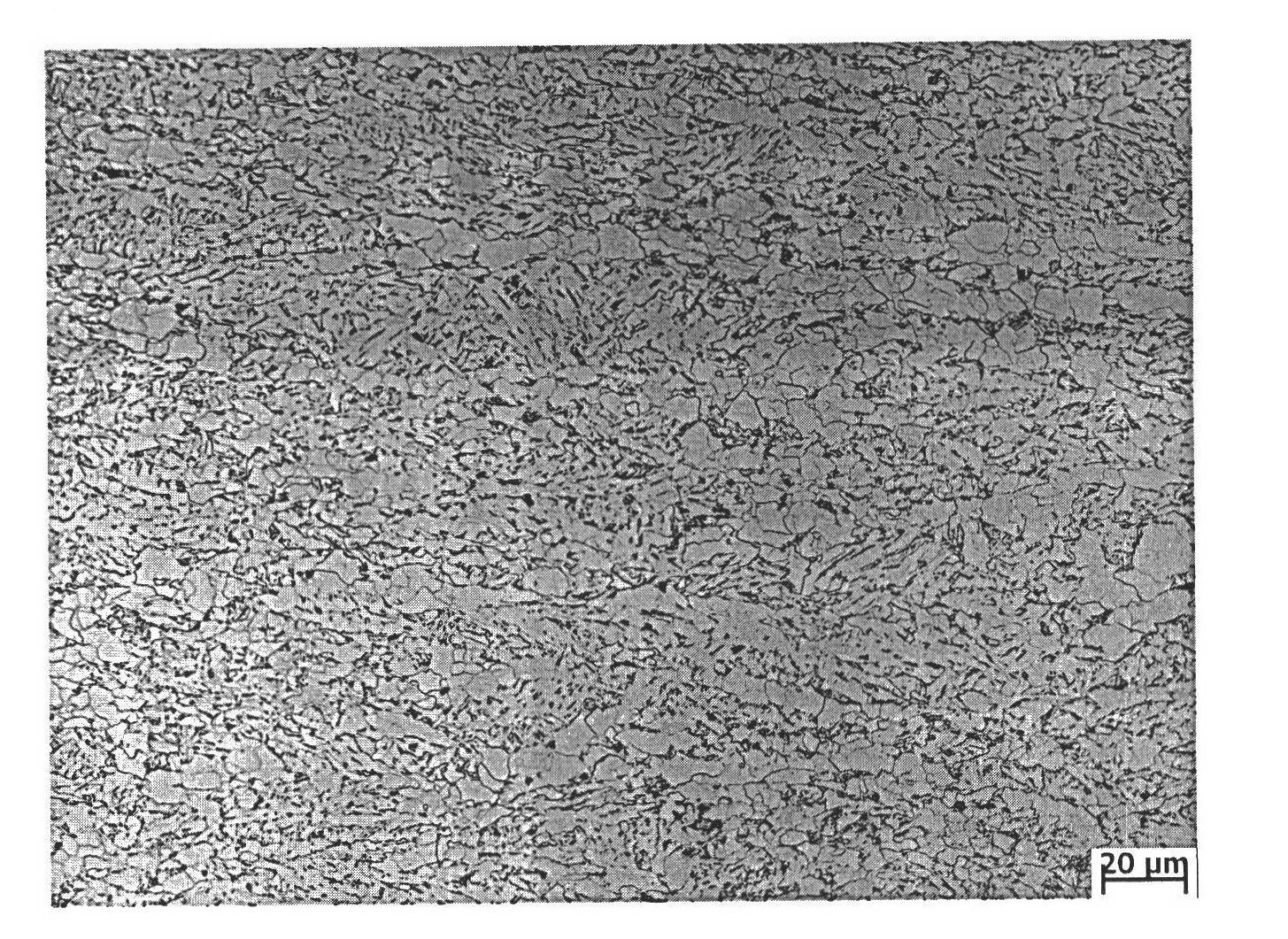

Embodiment 1

[0033] The chemical composition of smelted billets is C 0.06%, Si 0.26%, Mn 1.48%, P 0.0076%, S 0.0045%, Ni 0.14%, Cr 0.18%, Mo 0.12%, Nb 0.03%, V 0.04%, Ti 0.016%, Al ≤0.03%, N 0.006, the balance is Fe and unavoidable impurities, welding crack sensitivity index Pcm=0.166%.

[0034] The heating temperature of the billet before rolling is 1180°C and holding for 2 hours; the rough rolling temperature is 1080°C, the thickness reduction is 220→110mm; the finishing rolling temperature is 860°C, the final rolling temperature is 820°C, and the thickness reduction 110→40mm (reduction rate 0.64); after rolling, the steel plate enters the accelerated cooling device, and is cooled to 475℃ at a cooling rate of 16℃ / s, and then the steel plate is cooled to room temperature with water and air.

[0035] The yield strength of the rolled plate is 544Mpa, the tensile strength is 647Mpa, and the elongation after fracture is 23.8%; the low temperature impact properties of the rolled plate are shown in ...

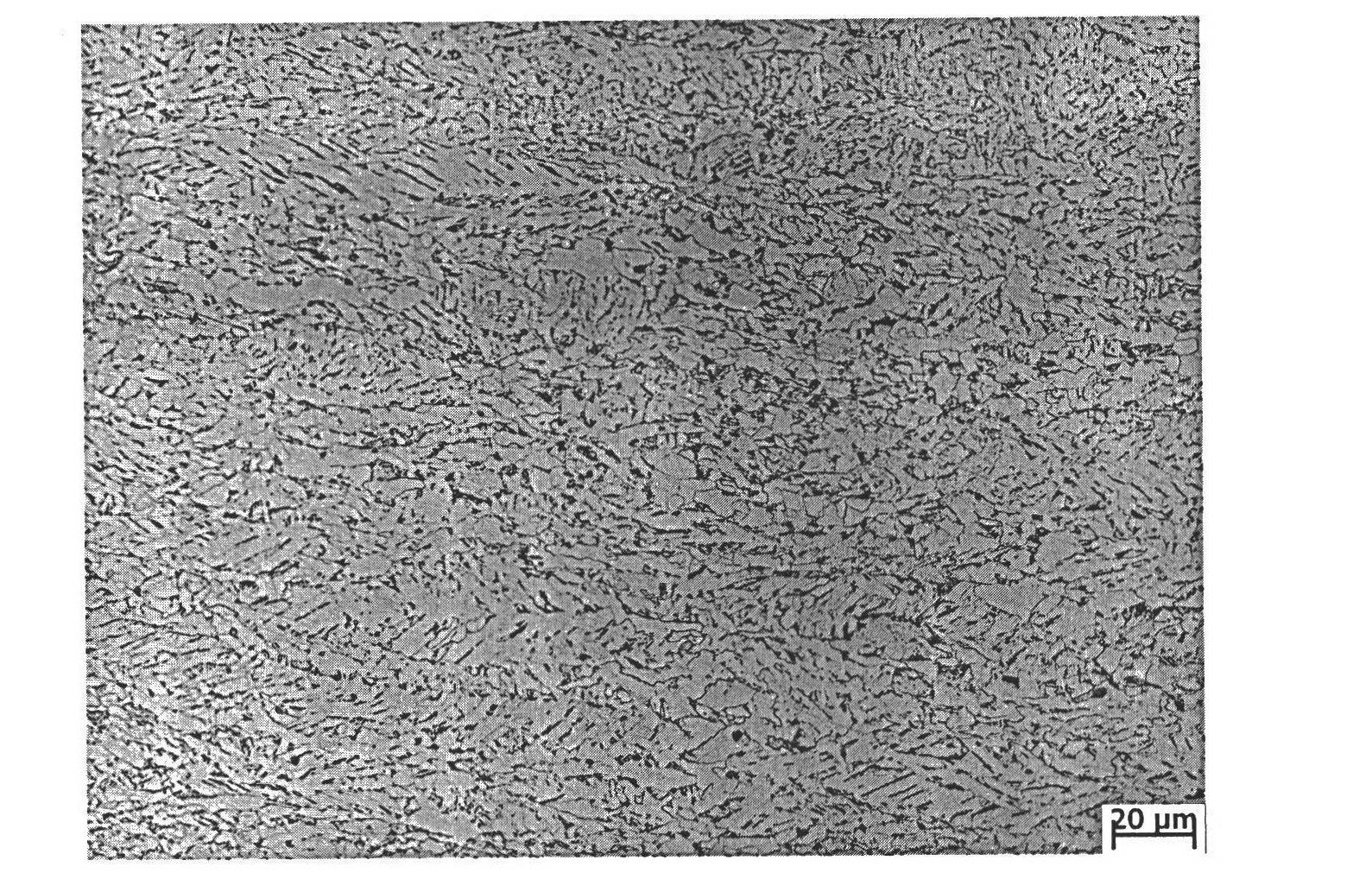

Embodiment 2

[0037] The chemical composition of the smelted billet is C 0.07%, Si 0.23%, Mn 1.52%, P 0.0082%, S 0.0042%, Ni 0.12%, Cr 0.18%, Mo 0.15%, Nb 0.02%, V 0.02%, Ti 0.012%, Al 0.03%, N 0.0055, the balance is Fe and unavoidable impurities, the welding crack sensitivity index Pcm=0.176%.

[0038] The heating temperature of the billet before rolling is 1180℃ and holding for 2 hours; the rough rolling temperature is 1080℃, the thickness reduction is 320→160mm; the finishing rolling temperature is 845℃, the final rolling temperature is 810℃, and the thickness reduction 160→60mm (reduction rate 0.62); after rolling, the steel plate enters the accelerated cooling device, and is cooled to 445℃ at a cooling rate of 22℃ / s, and then the steel plate is cooled to room temperature with water and air.

[0039] The yield strength of the rolled plate is 537Mpa, the tensile strength is 653Mpa, and the elongation after fracture is 25.8%; the low-temperature impact properties of the rolled plate are shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com