Method for controlling high-speed motion of electronic pattern sewing machine

A technology of high-speed motion and control method, applied in sewing machine control devices, sewing machine components, textiles and papermaking, etc., can solve problems such as reducing machine performance, slowing down system speed, and unsolved problems, achieving beautiful stitches, smooth operation, and noise. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] With reference to the accompanying drawings, we will describe the high-speed motion control method of the electronic pattern machine involved in the present invention in detail.

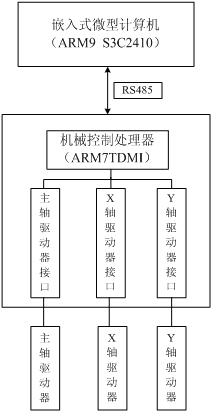

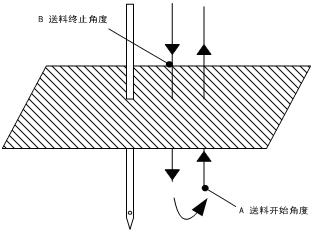

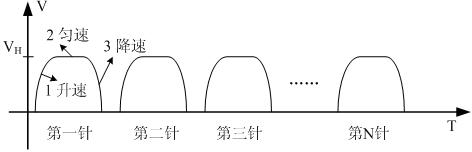

[0028] D It can be seen that the motion control method involved in the present invention is designed and implemented on the basis of developing the embedded control platform of the electronic pattern machine. The control system consists of two parts: ARM9 pattern processor with S3C2410 as the core and mechanical control processor with ARM7TDMI as the core, which are connected by serial port RS485. ARM9 has a very high degree of integration, is the core of the present invention, and is also the support for the implementation of the method provided by the present invention, including a human-machine interface unit, a pattern editing and modifying unit, etc.; ARM7 is mainly used to control the mechanical part of the pattern machine, including Embr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com