Multi-gear hydrodynamic transmission applicable to various working conditions

A technology of hydraulic transmission and hydraulic torque converter, which is applied in the field of multi-speed hydraulic transmission, can solve the problems of high labor intensity, inflexible operation, easy damage to structure, etc., and achieves high working reliability, convenient and flexible operation. , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

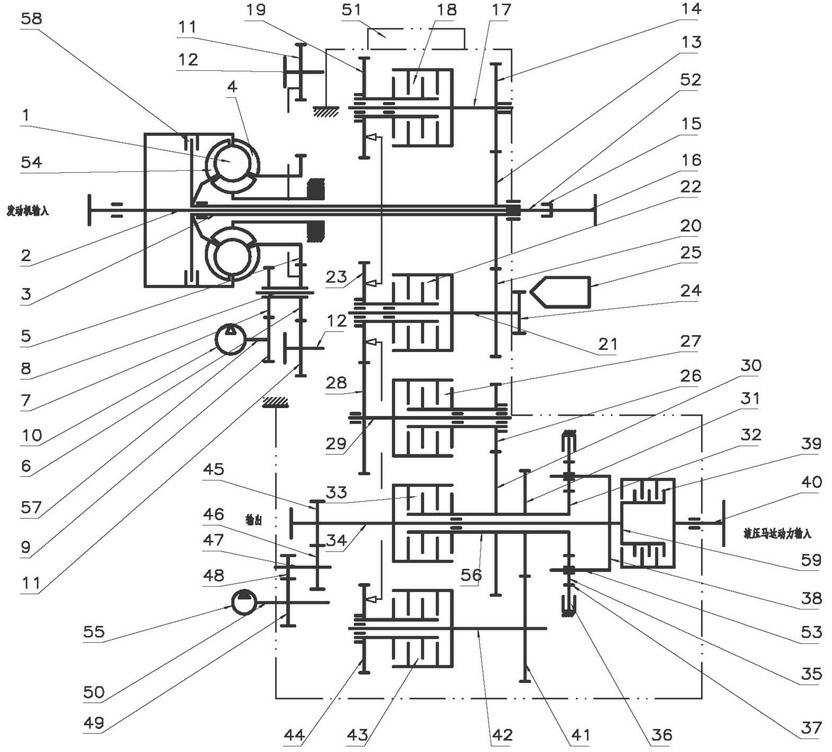

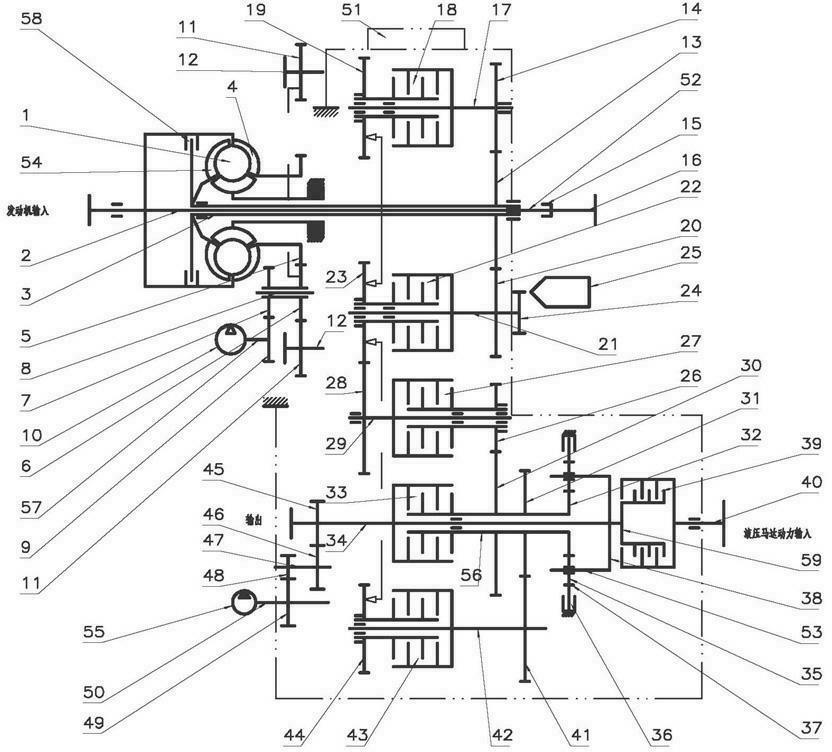

[0014] The transmission gear of the present invention has 4 forward gears, 4 reverse gears, 1 neutral gear, 1 power take-off port directly connected with the engine, and 2 power take-off ports indirectly connected with the engine;

[0015] 1. Traveling conditions

[0016] When the multi-plate wet friction clutches 22, 27 and the multi-plate wet friction brake 36 are combined, the input power→hydraulic torque converter 1→input shaft 3→input gear 13→transmission gear 20→KV shaft 21→transmission gear 23→transmission Gear 28→K1 / 3 shaft 29→transmission gear 26→transmission gear 30→transmission gear 32→planetary transmission→planet carrier 38→output shaft 34, to realize the power output of the first gear forward of the gearbox; when the multi-plate wet friction clutch 22, 43. When multi-plate wet friction brakes 36 are combined, input power→hydraulic torque converter 1→input shaft 3→input gear 13→transmission gear 20→KV shaft 21→transmission gear 23→transmission gear 44→K2 / 4 shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com