Fireworks and crackers material curing barn

A technology for fireworks and firecrackers and a barn, which is applied to dryers for static materials, local stirring dryers, drying rooms/containers, etc., can solve the problems of increasing production costs, danger, and high energy consumption of enterprises, and achieves simplified structure and production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

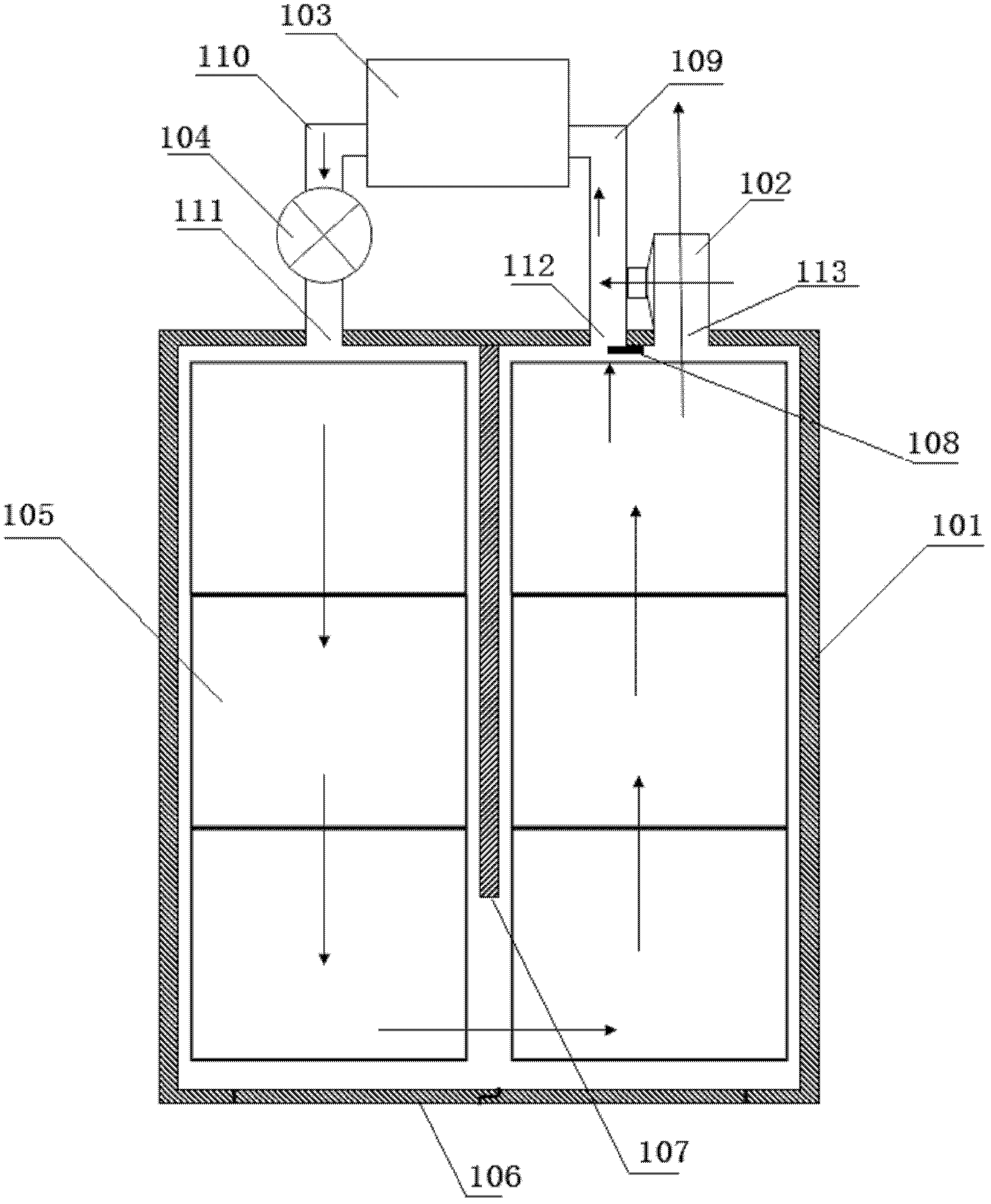

[0016] Referring to the accompanying drawings, reflecting a specific preferred structure of the present invention, the air inlet 111 and the return air outlet 112 of the inner cavity of the firework and firecracker material barn 101 are formed by connecting the air source heat pump 103 through the air inlet pipe 110 and the return air pipe 109 Heat source and fan 104, the inner cavity of the barn 101 is divided into two parts, the left cavity and the right cavity by the partition 107, the air inlet 111 is located in the left cavity, and the return air 112 is located in the right cavity, and the left cavity and the right cavity communicate with each other Form the left and right circulation air ducts. The barn 101 is provided with a barn door 106

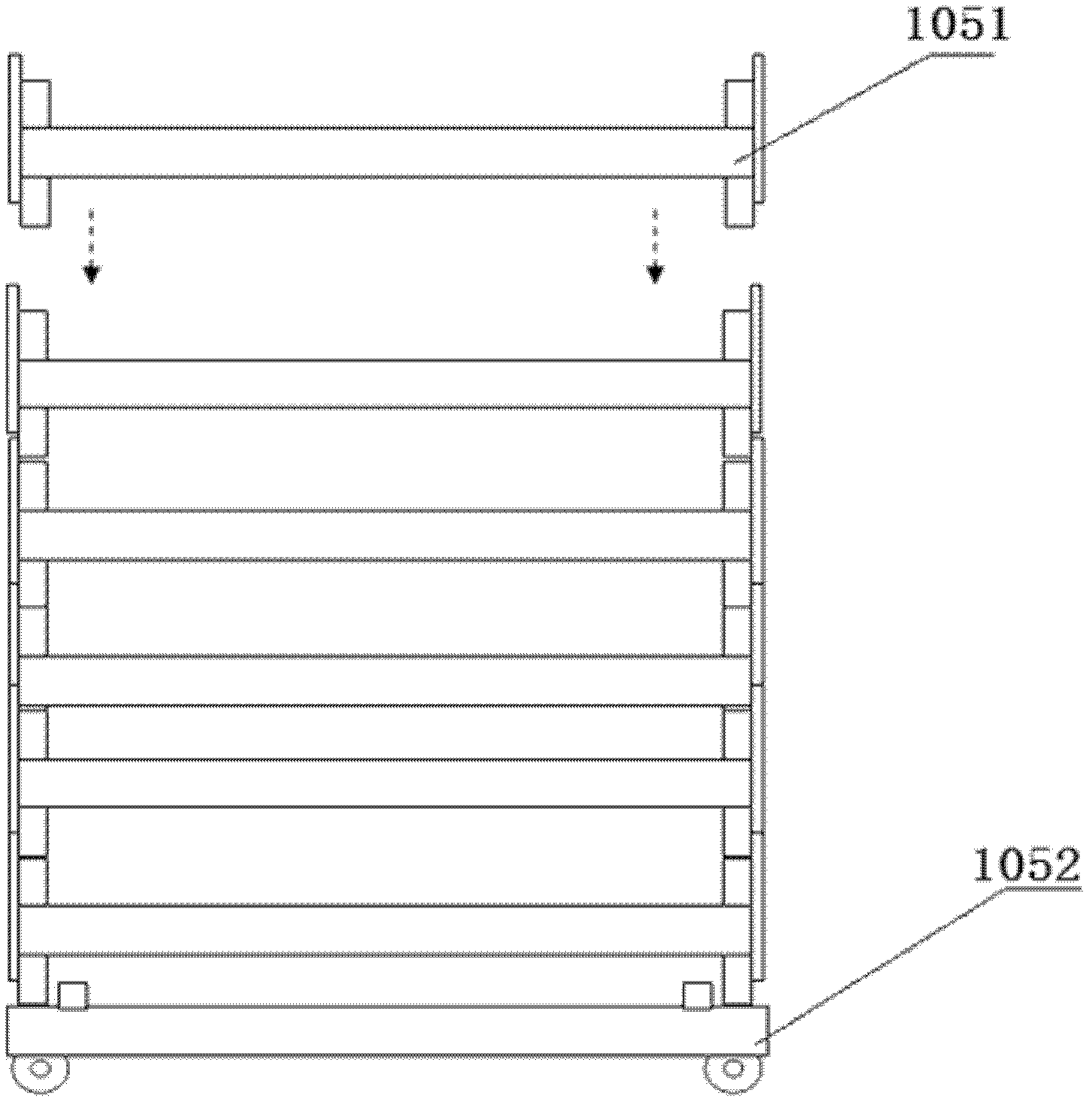

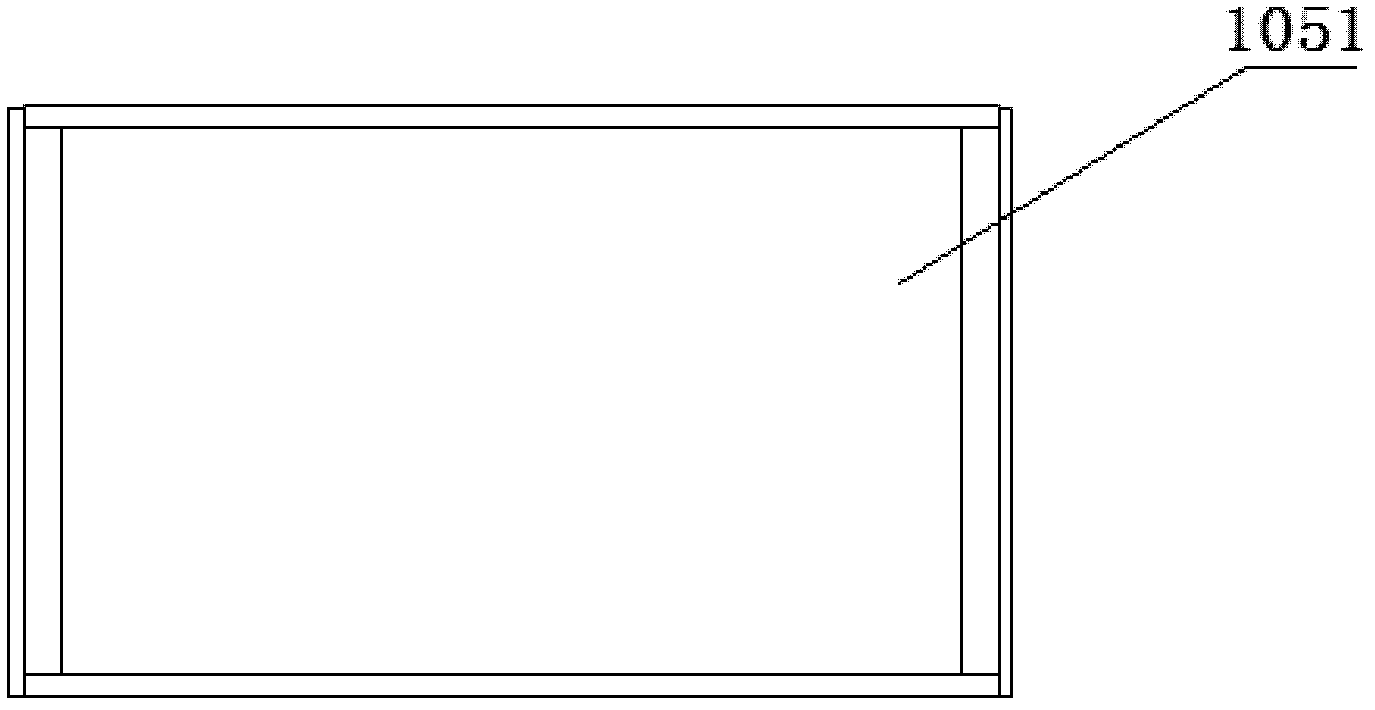

[0017] The barn 101 adopts a cart-type stacked material rack 105, and the cart-type stacked material rack 105 is composed of several independent wooden material tray units 1051 stacked on a trolley-type chassis 1052, and each layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com