Vacuum variable-temperature tube furnace

A tube furnace and vacuum technology, used in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of limited temperature range, experimental failure, and complicated operation, and achieve uniform and stable temperature field, good stability, and temperature range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

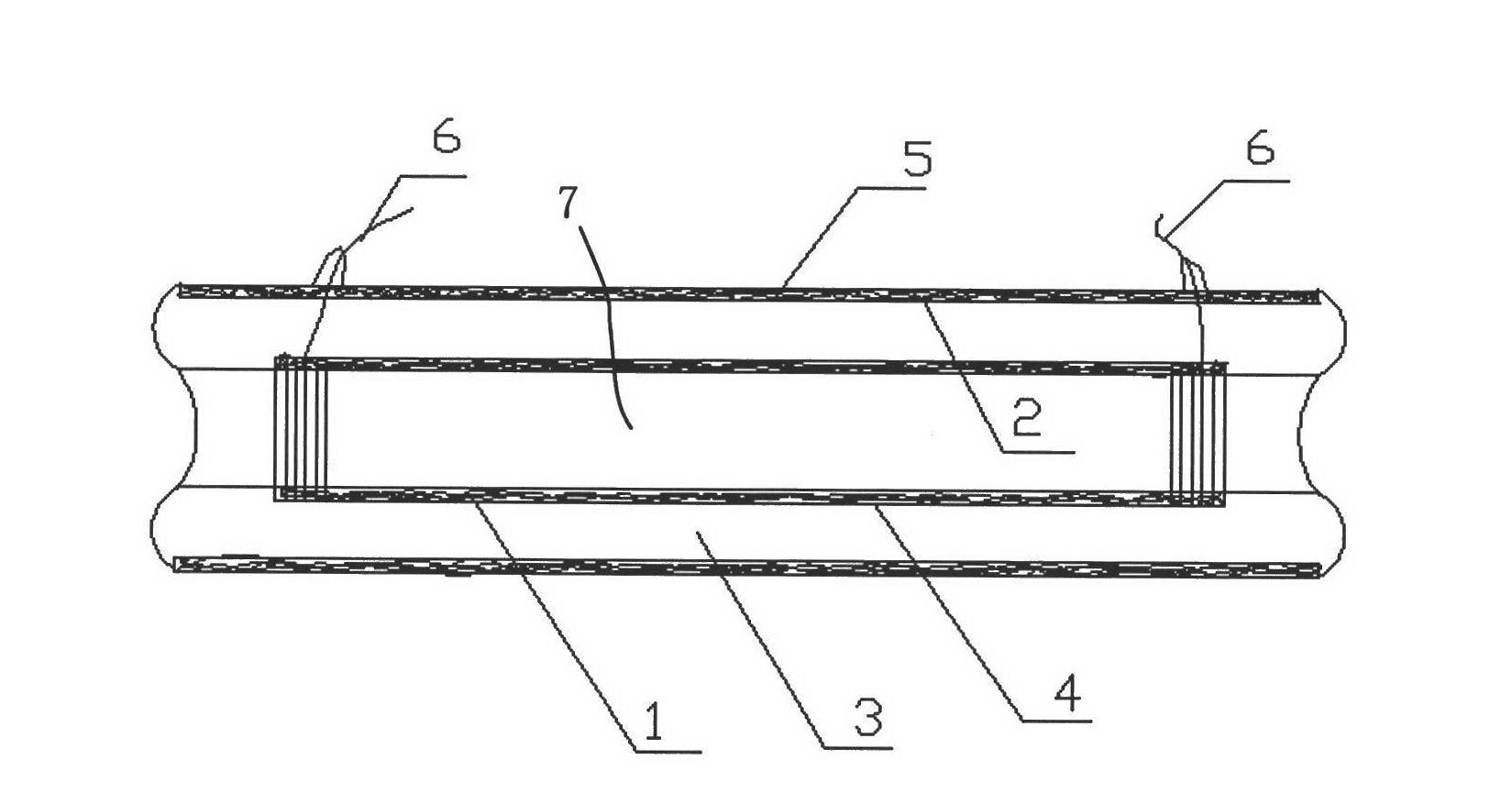

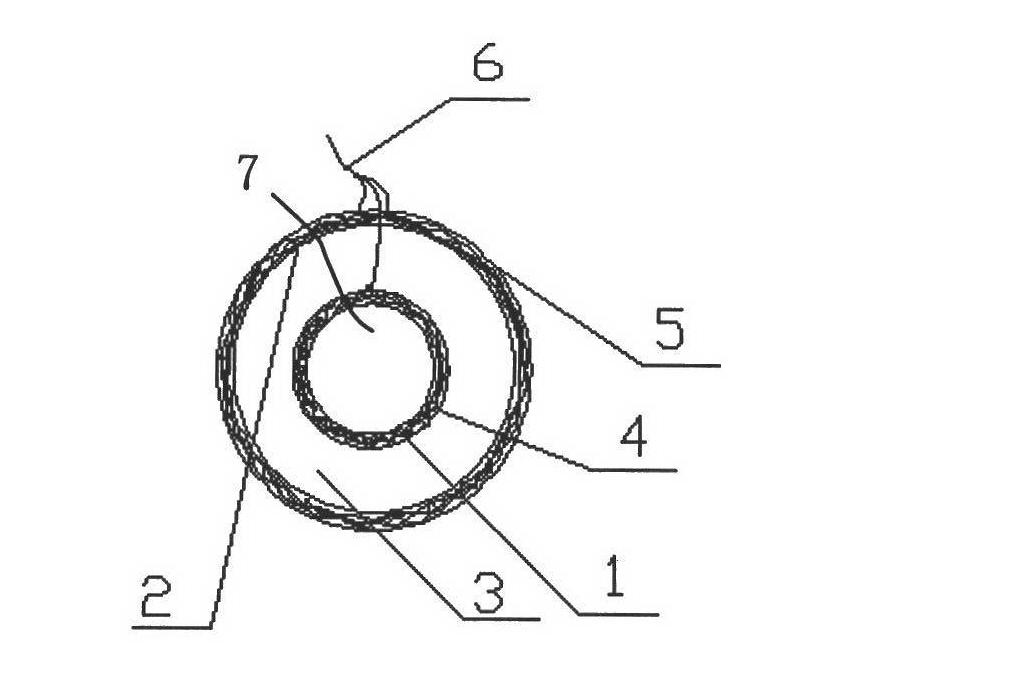

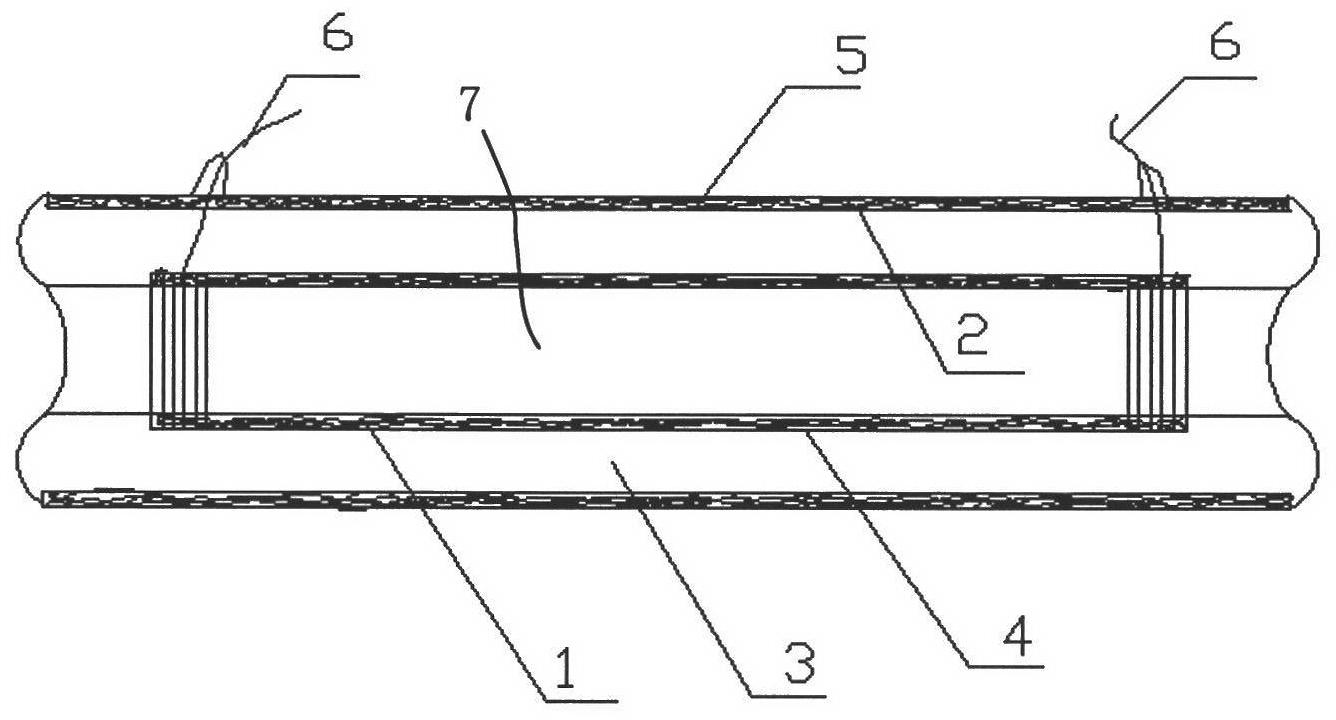

[0016] figure 1 It is a schematic diagram of the cross-sectional structure of the vacuum variable temperature tube furnace of the present invention, figure 2 It is a schematic diagram of the section structure of the vacuum variable temperature tube furnace of the present invention.

[0017] See figure 1 with figure 2 , the vacuum temperature-variable tube furnace inner glass tube 1 and the outer glass tube 2 provided by the present invention, the inner glass tube 1 and the outer glass tube 2 are sealed to form a hollow cylindrical tube, the inner glass tube 1 and the outer glass tube There is a vacuum layer 3 between the tubes 2, and the inner glass tube 1 is coated with an electric heating layer, and the two ends of the electric heating layer are led out from the electrode connecting wires 6 that run through the outer glass tube 2, and the inner g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com