Standard sampling device

A sampling device and standard technology, applied in the field of sample analysis, can solve the problems of low accuracy and precision of test results, low sampling uniformity, and easy blockage of sampling ports, etc., to achieve simple structure, ensure accuracy and precision , Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

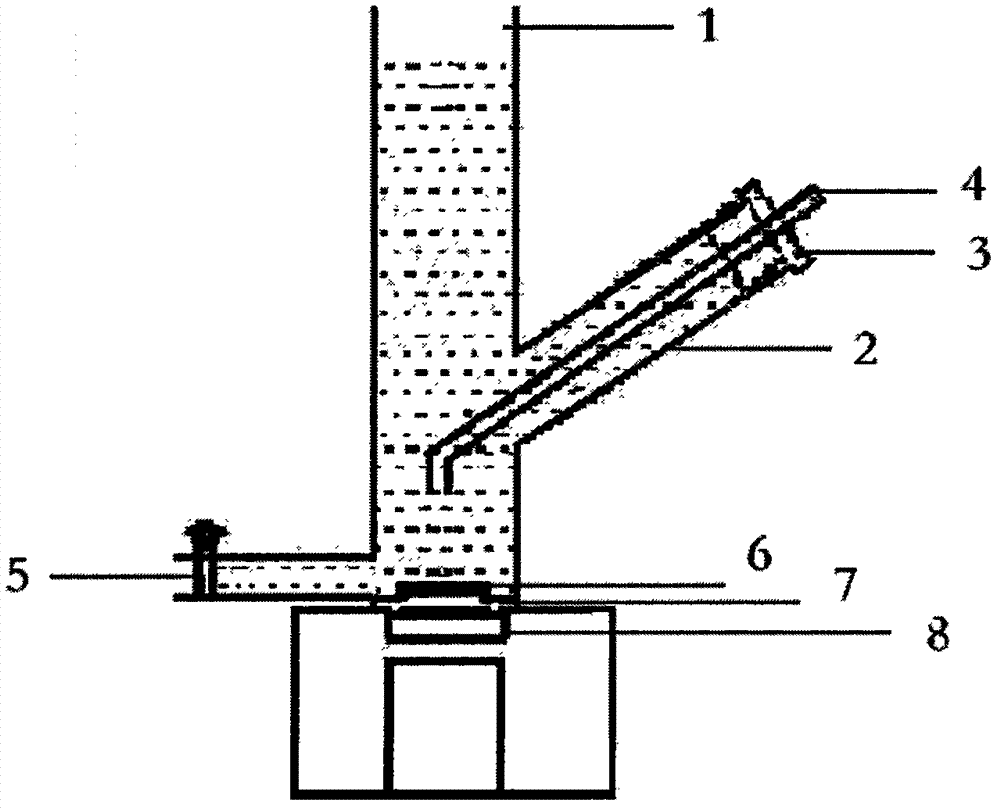

[0029] as attached figure 1 As shown, the standard sampling device described in this embodiment includes a liquid feeding pipe with an upper opening, a liquid taking pipe that communicates with the side of the liquid feeding pipe and is inclined upwards, a bottle stopper at the end of the liquid taking pipe, and a bottle from the liquid taking tube. The mouth plug extends to the liquid-taking pipe and the sampling suction pipe in the liquid-feeding pipe. The bottom side of the standard sampling device is provided with a waste liquid sample emptying port. The bottom of the standard sampling device is provided with a temperature control device. The temperature control device It includes a heating tube, a temperature detector and an ultrasonic atomization device arranged at the bottom of the liquid supply pipe. The ultrasonic atomization device includes an electric drive device, an ultrasonic atomization vibration plate and is connected to the ultrasonic atomization vibration plat...

Embodiment 2

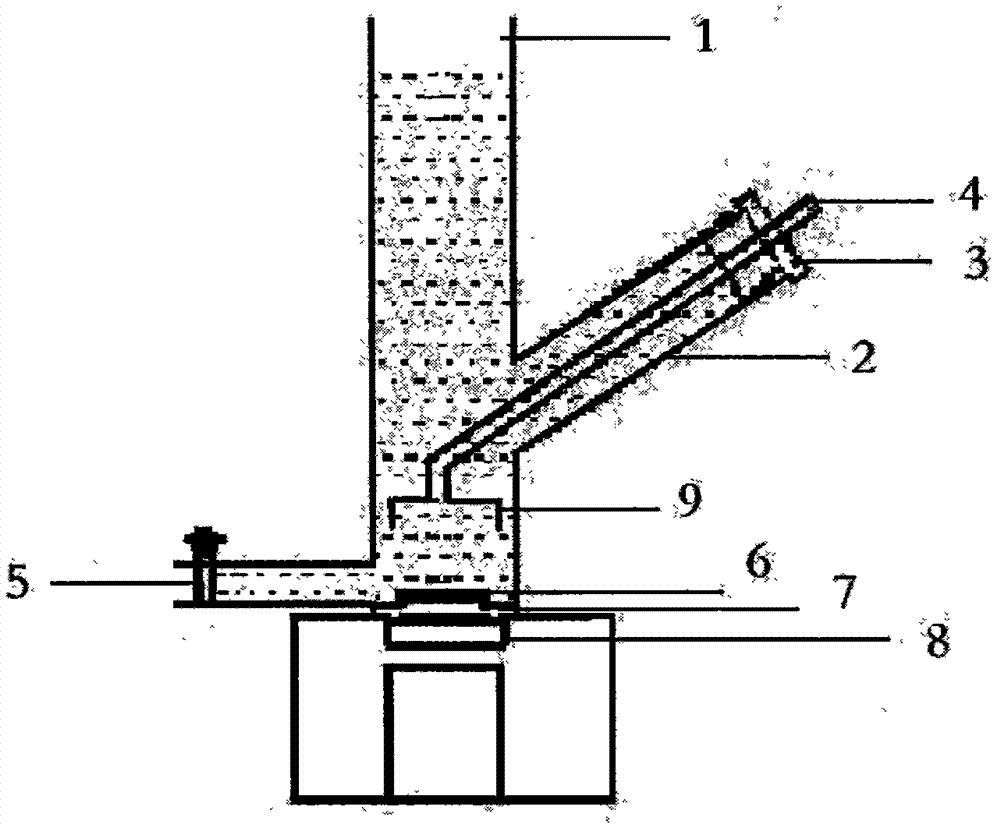

[0031] as attached figure 2 As shown, the standard sampling device described in this embodiment includes a liquid feeding pipe with an upper opening, a liquid taking pipe that communicates with the side of the liquid feeding pipe and is inclined upwards, a bottle stopper at the end of the liquid taking pipe, and a bottle from the liquid taking tube. The mouth plug extends to the liquid-taking pipe and the sampling suction pipe in the liquid-feeding pipe. The bottom side of the standard sampling device is provided with a waste liquid sample emptying port. The bottom of the standard sampling device is provided with a temperature control device. The temperature control device It includes a heating tube, a temperature detector and an ultrasonic atomization device arranged at the bottom of the liquid supply pipe. The ultrasonic atomization device includes an electric drive device, an ultrasonic atomization vibration plate and is connected to the ultrasonic atomization vibration pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com