Method for measuring porosity of porous ceramic material by using non-invasive liquid nitrogen

A technology of porous ceramics and porosity, applied in suspension and porous material analysis, measurement devices, permeability/surface area analysis, etc., can solve problems such as mass loss errors, inorganic damage, etc., to reduce the possibility of crack formation, reduce Injury, effect of reducing capital requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for measuring porosity with non-destructive liquid nitrogen, the method steps are as follows:

[0039] (1) Measurement of dry sample mass D;

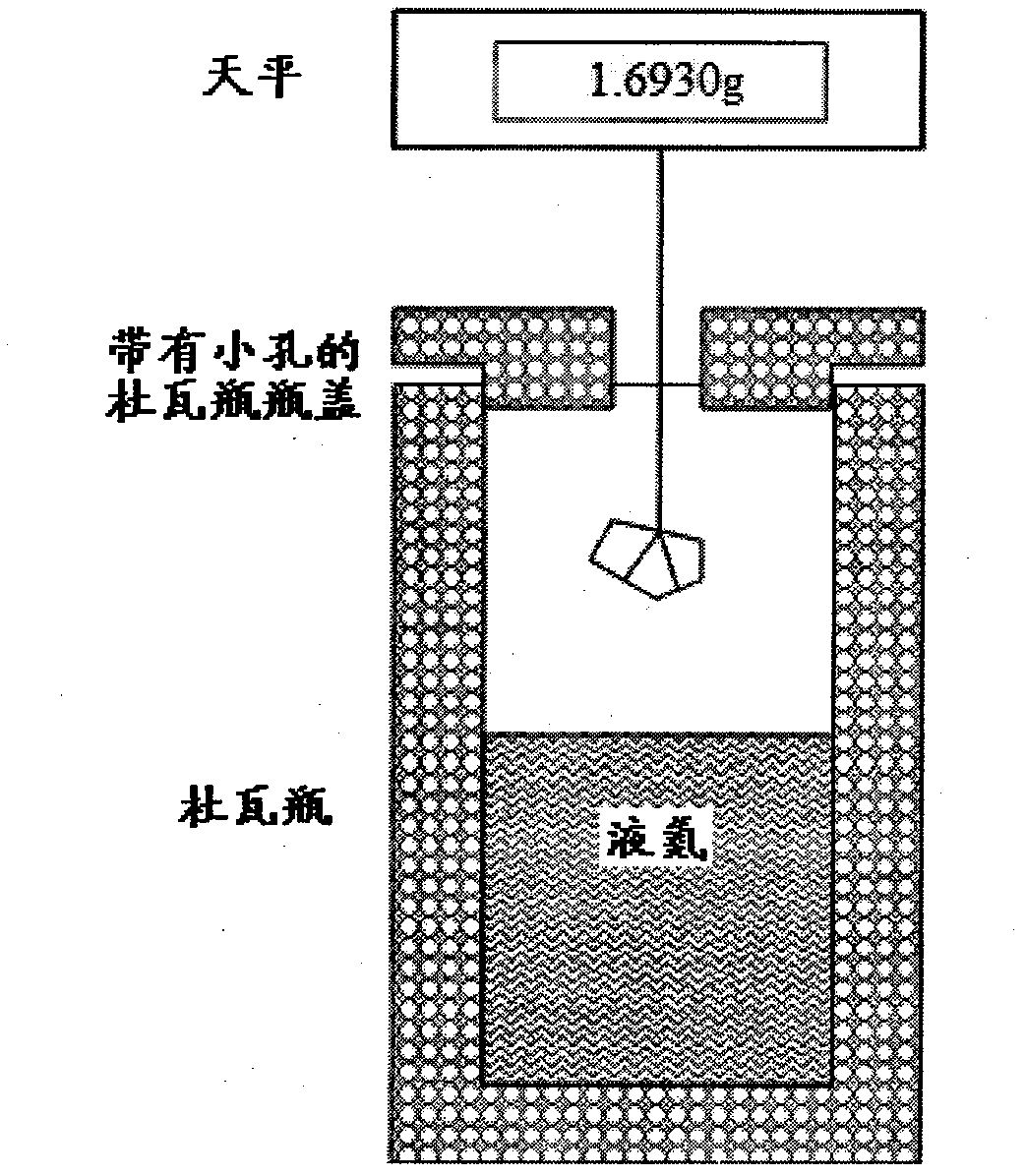

[0040] Hang the dry sample put into the copper wire mesh basket above the Dewar bottle filled with liquid nitrogen, after the sample is cooled, record the mass D at this time as 1.6930g;

[0041] (2) Measurement of the mass S of the saturated sample in liquid nitrogen;

[0042] Submerge the sample put into the copper mesh basket after cooling into liquid nitrogen completely, and when the reading of the mass of the sample in liquid nitrogen remains unchanged, record the mass S at this time as 1.4765g. ;

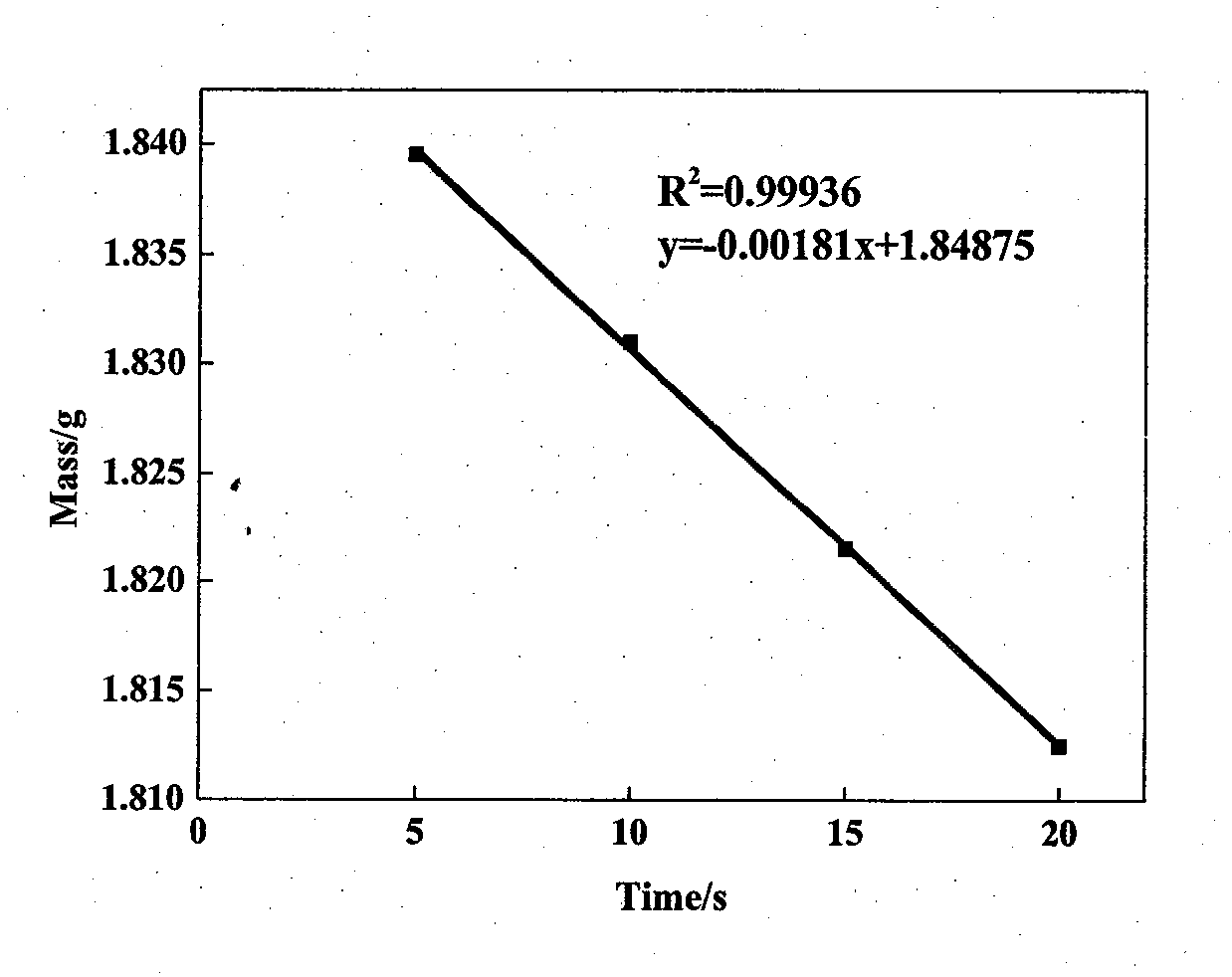

[0043] (3) Measurement of the mass W in the air at the moment when the saturated sample is taken out from the liquid nitrogen;

[0044] Take out the copper wire mesh basket filled with liquid nitrogen saturated sample from the liquid nitrogen, place it in the air, and record the mass W of the sample at different times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com