Magnetostrictive guided wave sensor

A magnetostrictive and sensor technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of irregular metal pipes, different sensitivity of guided wave excitation, etc., and achieve the effect of great social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

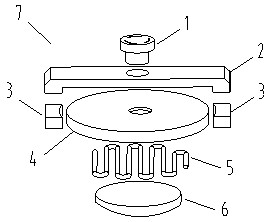

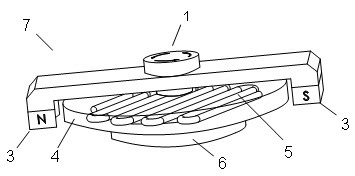

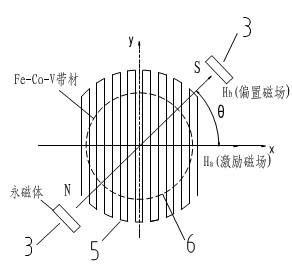

[0017] Such as figure 1 , figure 2 As shown, the magnetostrictive guided wave sensor 7 of the present invention is composed of a rotating bracket 1, a supporting bracket 2, a permanent magnet 3 with opposite polarities, a heat-resistant insulating layer 4, an excitation coil 5 and a Fe-CO-V disc 6. .

[0018] Two permanent magnets 3 with opposite polarities are fixed on the lower ends of both sides of the support bracket 2. After the rotating bracket 1 passes through the center hole of the support bracket 2, it is positioned in the center hole of the heat-resistant insulating layer 4 embedded with the excitation coil 5, and rotates The bracket 1 can drive the support bracket 2 to rotate, and the Fe-CO-V disk 6 is attached to the lower surface of the heat-resistant insulating layer 4, and the heat-resistant insulating layer 4 is located between two permanent magnets 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com