Low-voltage large-current output transformer

A technology for outputting transformers and large currents, applied in the field of transformers, which can solve the problems of lack of versatility of the left and right bases, small transformer output current, etc., and achieve the advantages of convenient production and assembly, small self-loss, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

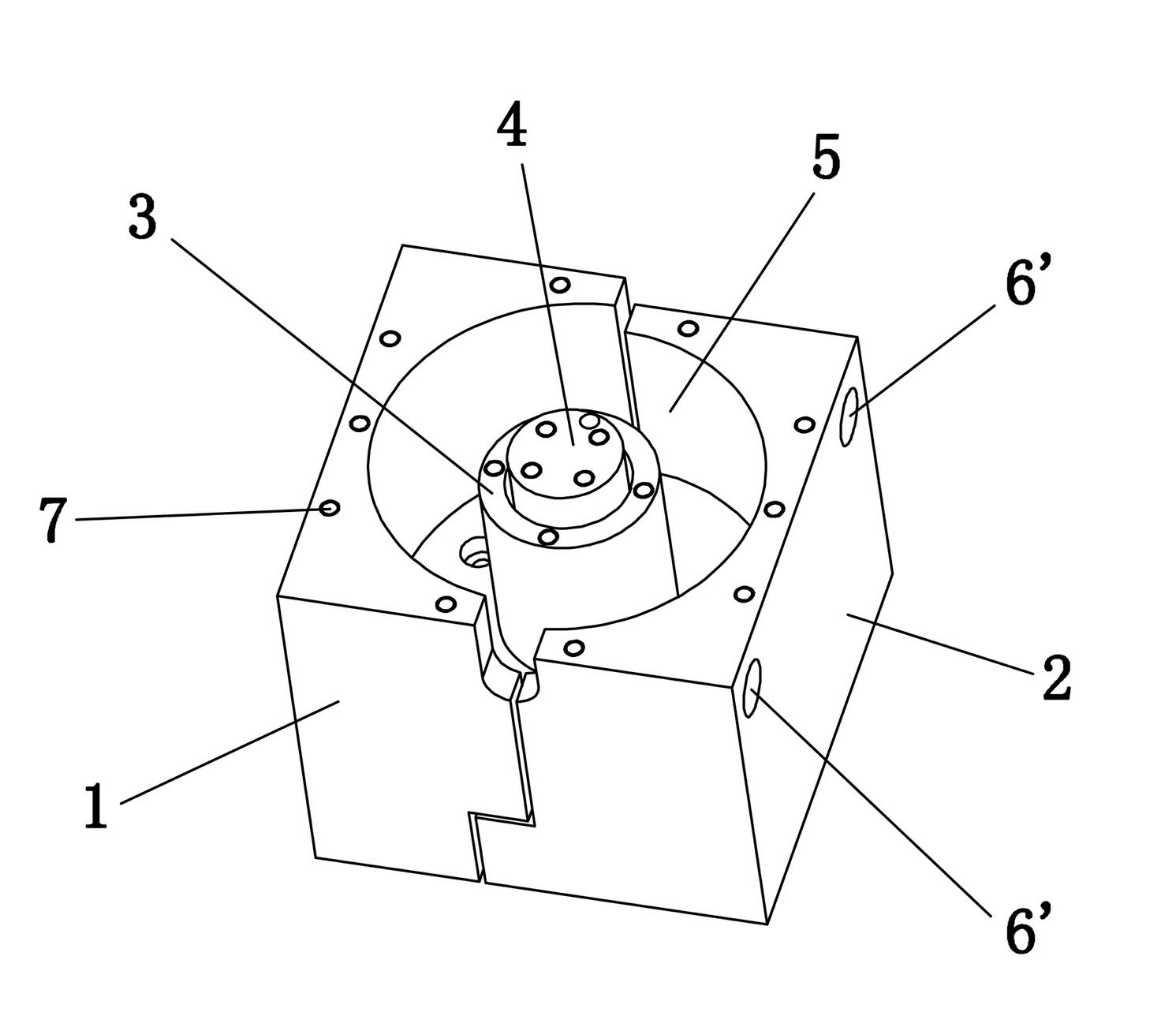

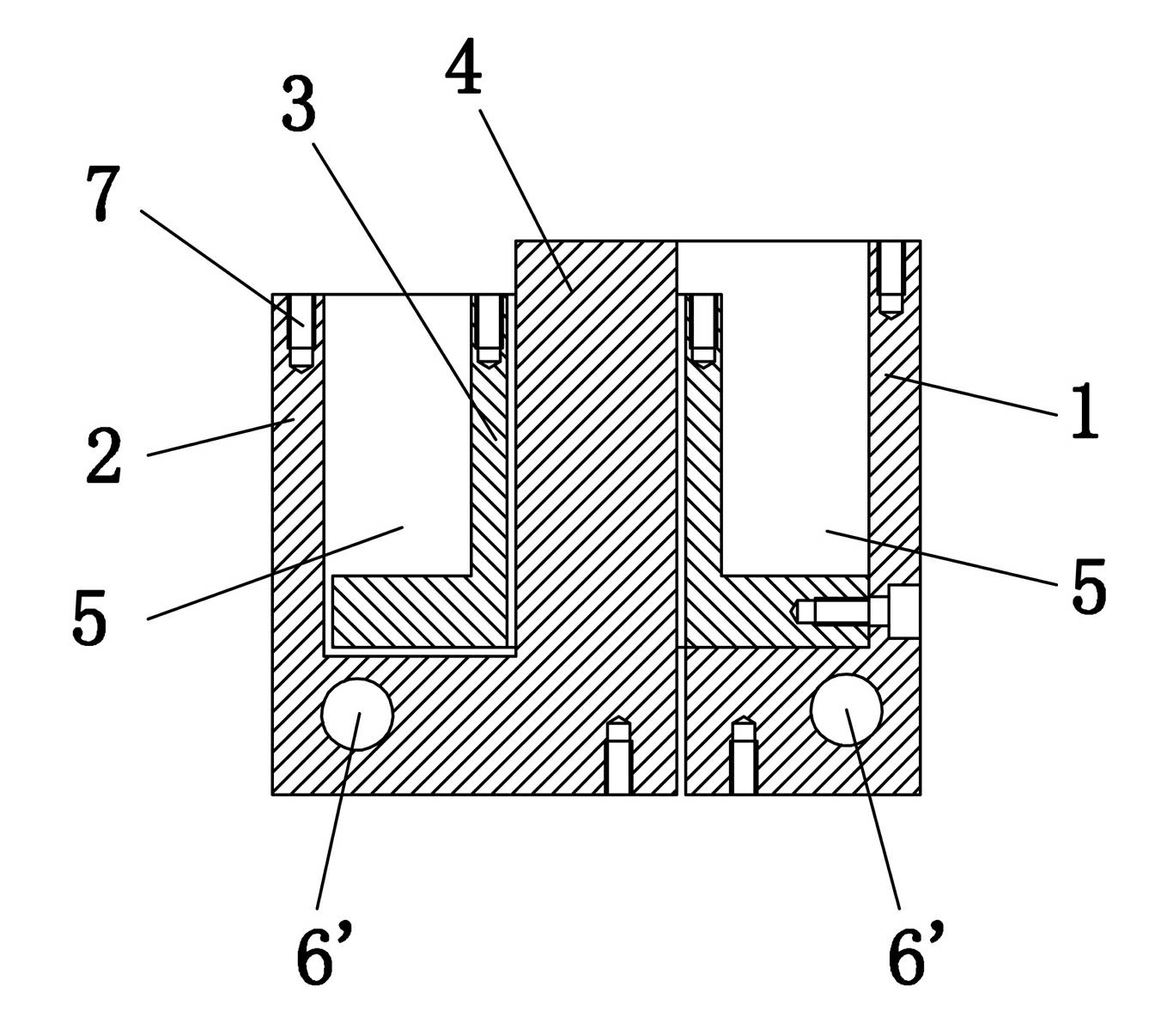

[0028] refer to Figure 1 to Figure 6 , a low-voltage high-current output transformer, including a primary winding wound on an iron core and a secondary winding wrapped outside the primary winding, the secondary winding is assembled from the following independent components:

[0029] The first seat body is provided with an arc-shaped groove 9 , and the arc-shaped groove 9 divides the first seat body into a first secondary side 2 and a cylindrical first central column 4 .

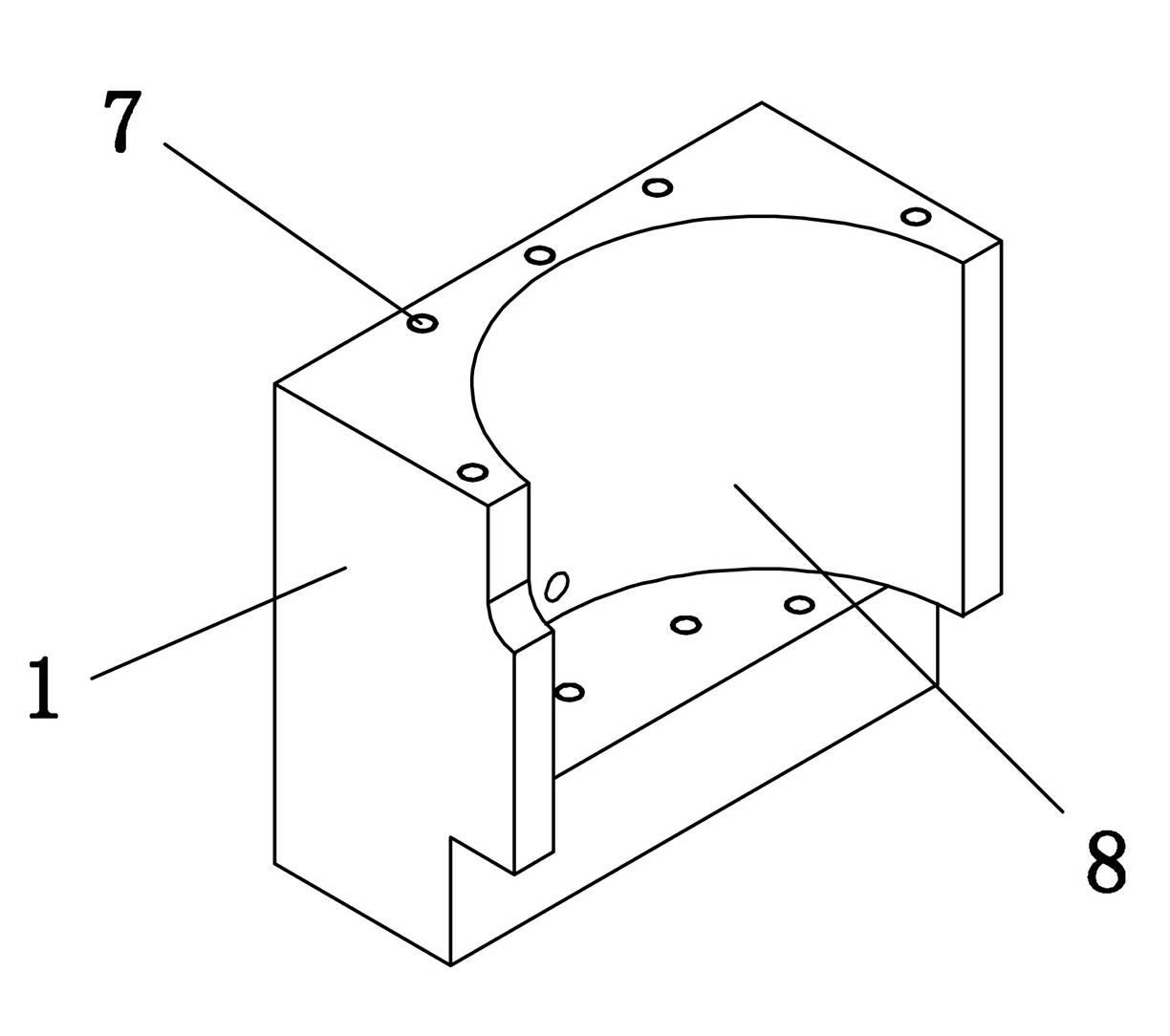

[0030] The second seat body 1 is provided with a semi-cylindrical notch 8 .

[0031] The lower end of the tubular second central column 3 is fixed in the semi-cylindrical notch 8 of the second base body 1 by screws.

[0032] After the first seat body and the second seat body are assembled, the first center column 4 is inserted through the tube center of the second center column 3 , and the top of the first center column 4 is higher than the top of the second center column 3 . Top; between the arc-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com