Preparation method of lithium titanate (Li4Ti5O12)/Ag composite lithium-ion negative electrode materials

A negative electrode material and lithium ion technology, which is applied in the field of electrochemical battery material preparation, can solve the problems of poor high-rate charge-discharge performance and large energy consumption of lithium titanate materials, and achieves favorable migration and migration, uniform structure, and high energy consumption. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation process and steps in this embodiment are as follows:

[0023] (1) Dissolving isopropyl titanate in a certain amount of deionized water is A liquid;

[0024] (2) Lithium hydroxide monohydrate is dissolved in a certain amount of deionized water, and the atomic molar ratio n of the two is maintained Li :n Ti =1:1.1, according to 1‰Ag of the product mass, add silver nitrate solution source to be B liquid;

[0025] (3) Slowly add liquid B into liquid A under magnetic stirring, and stir for 30 minutes;

[0026] (4) Pour the mixed solution into a high-temperature reaction kettle, and then place it in an oven at 160°C for 10 hours to react. After the reaction, naturally cool to room temperature, then perform suction filtration, wash with deionized water, and dry at 60°C to obtain the precursor;

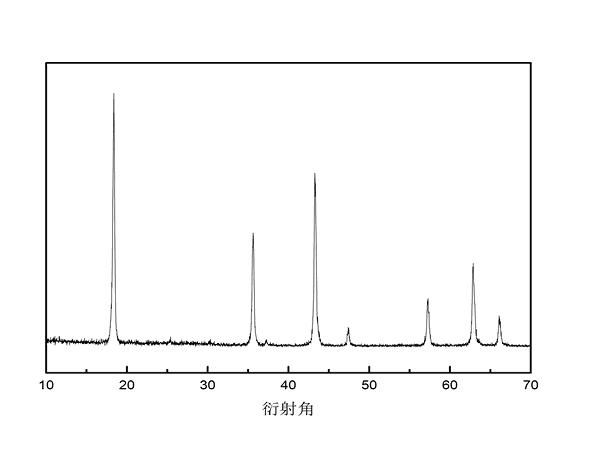

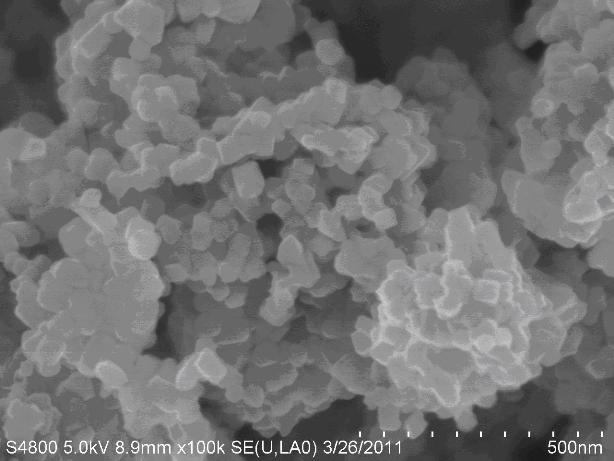

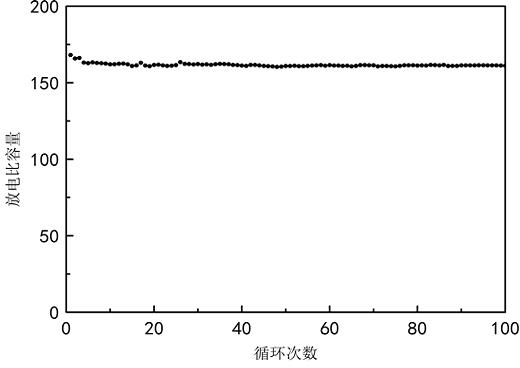

[0027] (5) The obtained precursor was sintered at 500 °C for 2 h under a nitrogen atmosphere, and the obtained product was nanoscale Li 4 Ti 5 o 12 / Ag material. ...

Embodiment 2

[0032] The preparation process and steps in this embodiment are as follows:

[0033] (1) the amorphous TiO 2 Dissolve in a certain amount of deionized water to form A liquid;

[0034] (2) Lithium acetate is dissolved in a certain amount of deionized water, and the atomic molar ratio n of the two is maintained Li :n Ti =1:1.1, add silver nitrate solution according to 5‰ of the product weight, and it is B liquid;

[0035] (3) Slowly add liquid B into liquid A under magnetic stirring, and stir for 30 minutes;

[0036] (4) Pour the mixed solution into a high-temperature reaction kettle, and then place it in an oven at 120°C for 14 hours to react. After the reaction, naturally cool to room temperature, then perform suction filtration, wash with deionized water, and dry at 60°C to obtain the precursor;

[0037] (5) The obtained precursor was sintered at 600° C. for 5 h under a nitrogen atmosphere, and the obtained product was a pure lithium titanate material.

[0038] The test me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com