Composite plant and animal canning method

A processing method, animal and plant technology, applied in the field of food processing, can solve the problems of long production and processing process, products containing nitrite, and single meat variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

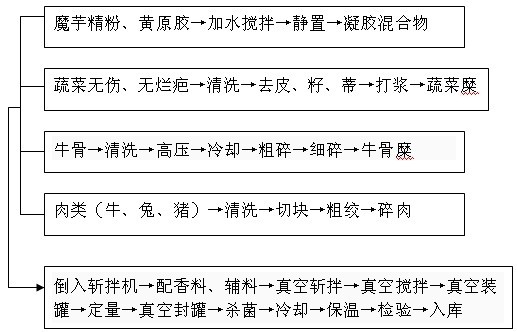

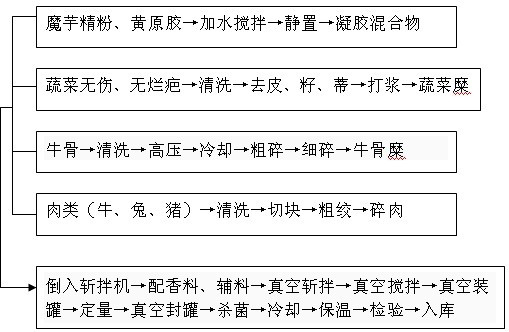

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 3.5% konjac powder by mass and 0.25% xanthan gum to water, stir continuously for 12 minutes, and let stand for 6 hours to obtain a gel mixture;

[0019] (2) Cook the carrots to remove the raw smell, then put them into a beater or chopping machine according to the mass ratio of carrots:tomatoes:shiitake mushrooms is 6:3:1, and make vegetable mince, and use the same method to separate Prepare minced green onion and minced ginger separately;

[0020] (3) Wash the beef bones and put them in a pressure cooker at a temperature of 135-145°C and a pressure of 3-4kg / ㎝ 2 Under treatment for 40 minutes, cooled and crushed to obtain minced beef bone;

[0021] (4) According to the ratio of 45% beef, 30% rabbit meat, 20% pork (half fat and thin), and 5% minced beef bone, take frozen beef, rabbit meat and pork, and thaw them in plastic turnover boxes to prevent meat Then cut the meat strips into 8-10cm long and 3-5cm wide strips, grind them into minced meat with an 8mm hole-...

Embodiment 2

[0025] (1) Add 2% konjac powder by mass and 0.1% xanthan gum to water, stir continuously for 10 minutes, and let stand for 5 hours to obtain a gel mixture;

[0026] (2) Cook the carrots to remove the raw smell, then put them into a beater or chopping machine according to the mass ratio of carrots:tomatoes:shiitake mushrooms is 6:3:1, and make vegetable mince, and use the same method to separate Prepare minced green onion and minced ginger separately;

[0027] (3) Wash the beef bones and put them in a pressure cooker at a temperature of 135-145°C and a pressure of 3-4kg / ㎝ 2 Under treatment for 35 minutes, cooled and crushed to obtain minced beef bone;

[0028] (4) According to the ratio of 45% beef, 30% rabbit meat, 20% pork (half fat and thin), and 5% minced beef bone, take fresh beef, rabbit meat and pork, wash and cut into 8-10 ㎝, 3-5㎝ wide meat strips, minced meat with an 8㎜ hole-diameter twisting board, and added beef bone mince to obtain a meat mixture;

[0029] (5) ...

Embodiment 3

[0032] (1) Add 5% konjac powder by mass and 0.4% xanthan gum to water, stir continuously for 15 minutes, and let stand for 7 hours to obtain a gel mixture;

[0033] (2) Cook the carrots to remove the raw smell, then put them into a beater or chopping machine according to the mass ratio of carrots:tomatoes:shiitake mushrooms is 6:3:1, and make vegetable mince, and use the same method to separate Prepare minced green onion and minced ginger separately;

[0034] (3) Wash the beef bones and put them in a pressure cooker at a temperature of 135-145°C and a pressure of 3-4kg / ㎝ 2 Under processing for 45 minutes, after cooling, pulverize to obtain minced beef bone;

[0035] (4) According to the ratio of 45% beef, 30% rabbit meat, 20% pork (half fat and thin), and 5% minced beef bone, take fresh beef, rabbit meat and pork, wash and cut into 8-10 ㎝, 3-5㎝ wide meat strips, minced meat with 8㎜ aperture twisting board, add beef bone mince to get meat mixture;

[0036] (5) Pour the meat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com