Layered quick design and manufacturing method for individualized artificial bone injection and solidification molding die

A technology of injection molding and manufacturing methods, which can be used in prostheses, bone implants, medical science, etc., can solve problems such as short manufacturing cycles, achieve the effects of shortening manufacturing time, overcoming surface step defects, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

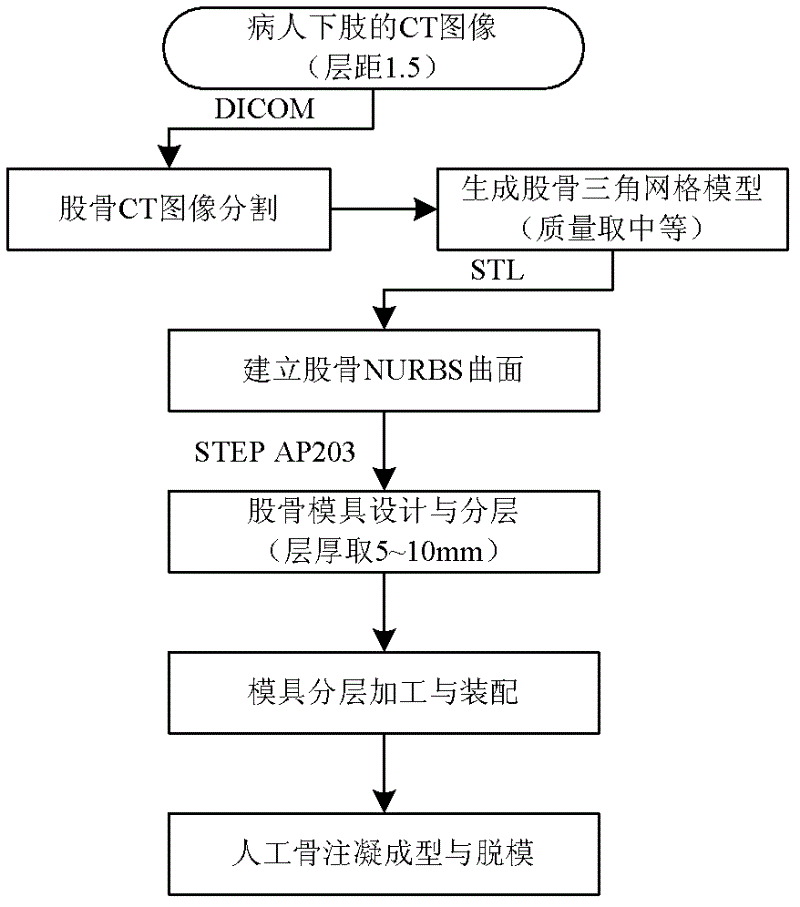

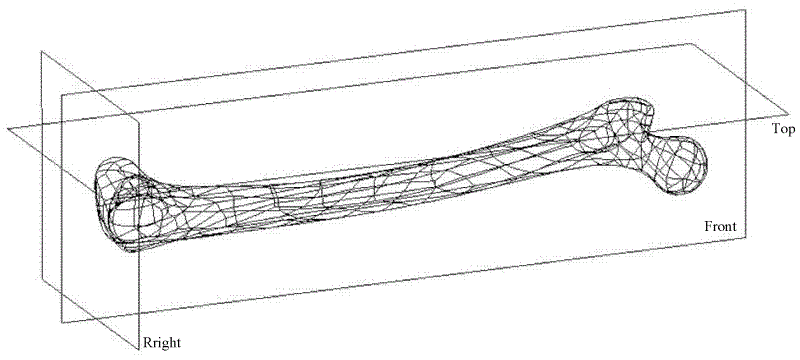

[0050] Embodiment: A layered rapid design and manufacturing method of an individualized artificial femur injection molding mold, including the following steps (see the overall processing flow in figure 1 ):

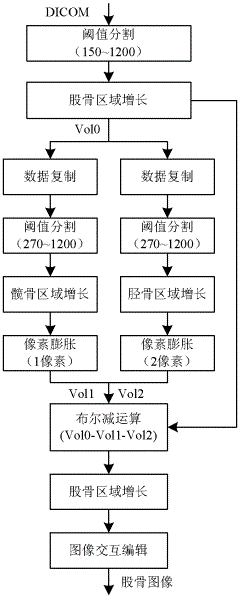

[0051] (1) Segmentation of femoral CT images and establishment of 3D models, including the following sub-steps (for the segmentation process of femoral CT images, see figure 2 ):

[0052] ⅰ) Collect CT scan images of the patient's lower limbs, with a layer spacing of 1.5mm (the smaller the image layer spacing, the more accurate the modeling result, but the maximum should not exceed 3mm), export in DICOM format, use Mimics (or 3DMed and other image processing software) to open CT data in DICOM format.

[0053] ii) Perform threshold segmentation on the entire image data set, set the CT value range from 150 to 1200 (the CT value range of other target bones should be adjusted appropriately), and then use the region growing method to extract the femur. At this time, the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com