Methanol-water reforming hydrogen production device and method for preparing hydrogen by using same

A technology for steam reforming and hydrogen production equipment, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as polluting the environment, ineffective use of gas, and inability to meet the low temperature requirements of catalysts, so as to reduce environmental pollution, The effect of improving the effective utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

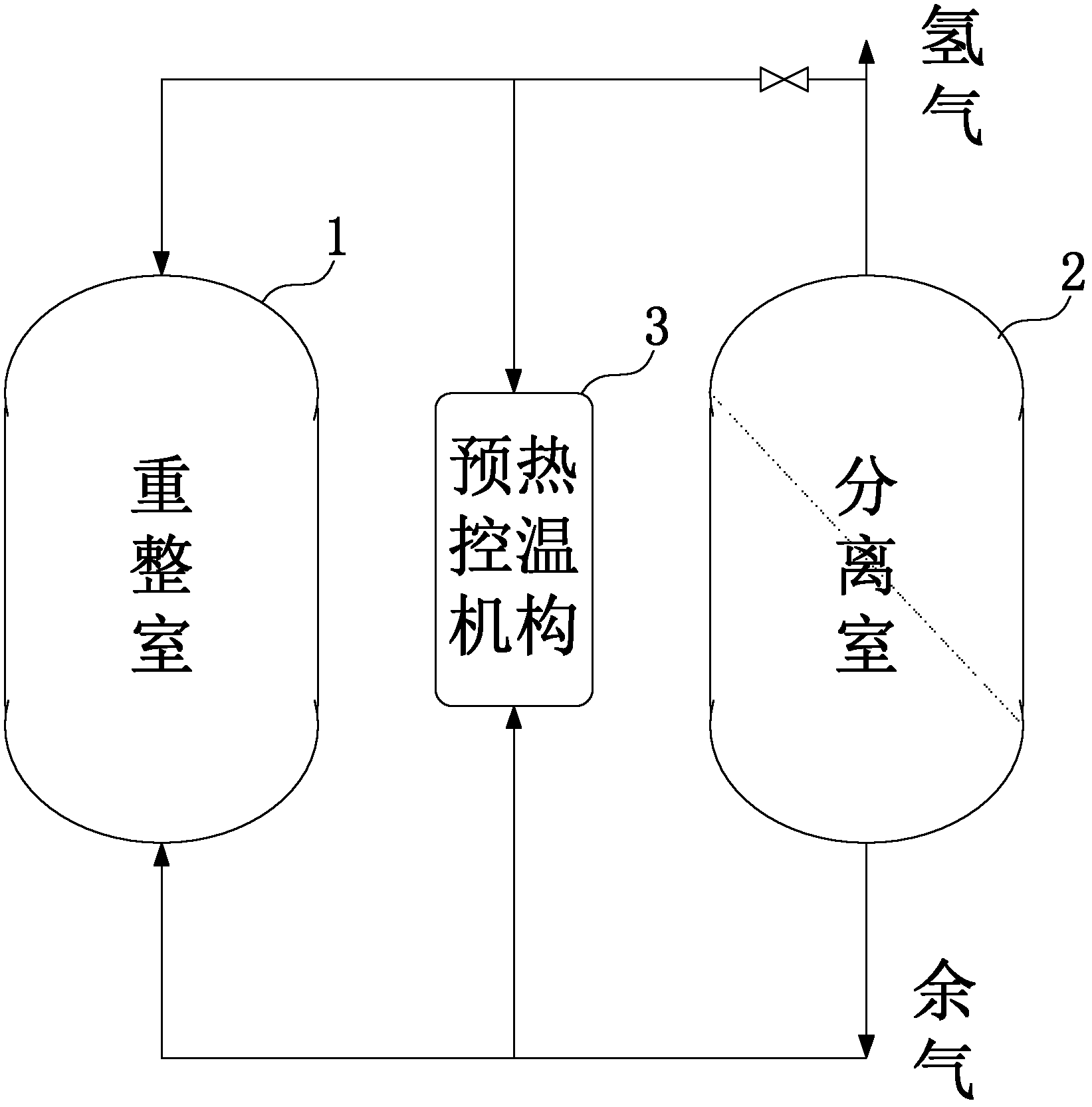

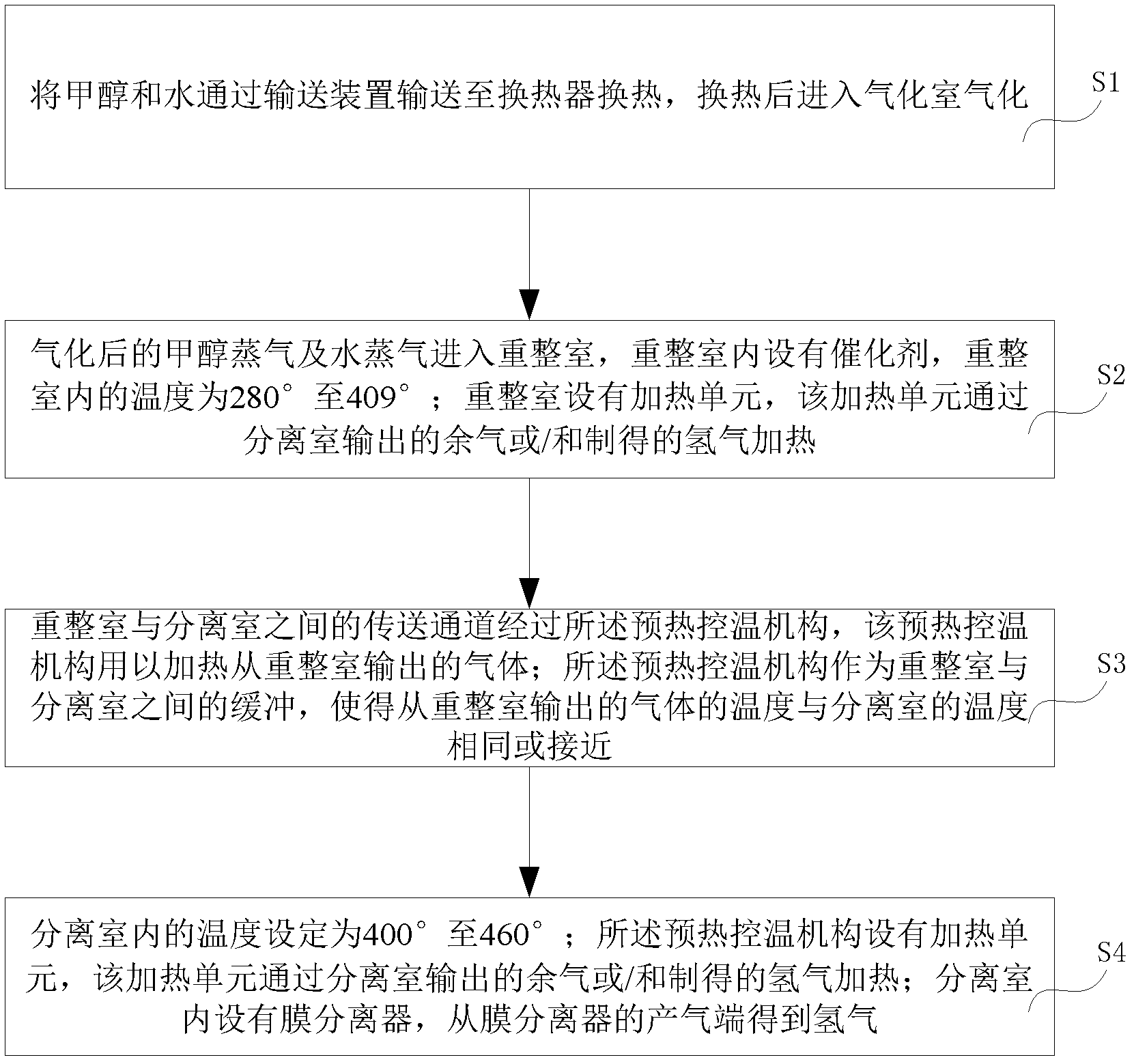

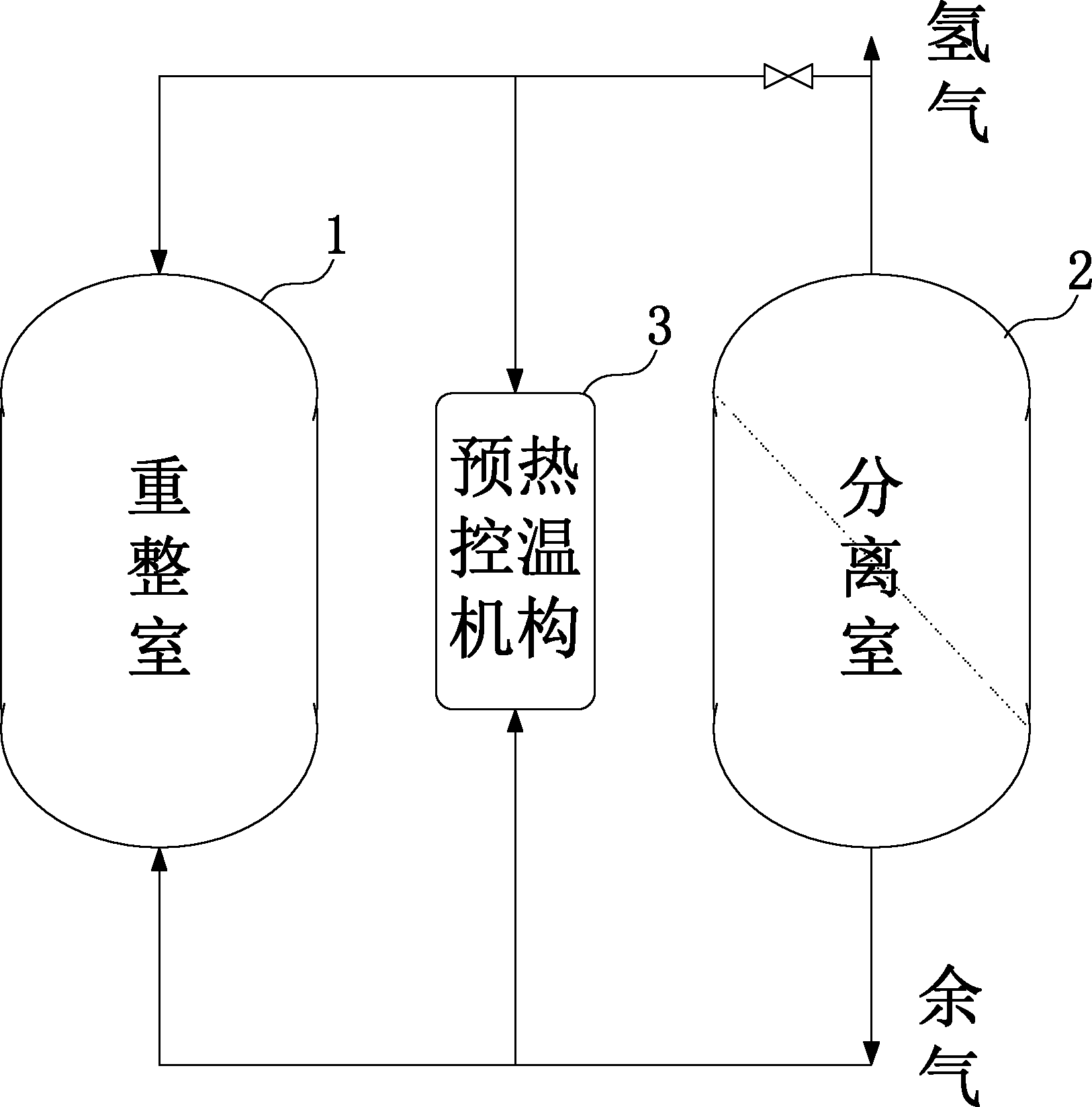

[0053] see figure 1 , the present invention discloses a methanol steam reforming hydrogen production equipment, the equipment includes: a liquid storage container, a heat exchanger, a gasification chamber, a reforming chamber 1, a separation chamber 2; the liquid storage container, heat exchange The device, the gasification chamber, the reforming chamber 1, and the separation chamber 2 are connected in sequence through pipelines.

[0054] In this example, the temperature in the reforming chamber 1 is set at 370°-409°, and in one embodiment of the present invention, the temperature in the reforming chamber 1 is set at 370°-400°, such as The temperature in the reforming chamber 1 can be set to 380°.

[0055] The temperature of the separation chamber 2 is set at 410°-430°, and the temperature in the separation chamber 2 is higher than that in the reforming chamber 1 .

[0056] The transmission channel between the reforming chamber 1 and the separation chamber 2 passes through a...

Embodiment 2

[0071] In this embodiment, the methanol steam reforming hydrogen production equipment includes: a liquid storage container, a heat exchanger, a gasification chamber, a reforming chamber, and a separation chamber; the liquid storage container, a heat exchanger, a gasification chamber, and a reforming chamber The chamber and the separation chamber are connected in sequence through pipelines.

[0072] The equipment includes one or more heating units to control the temperature of the components of the hydrogen production equipment that require temperature control (such as the reforming chamber or / and the preheating temperature control mechanism or / and the separation chamber); the output of the heating unit through the separation chamber The residual gas or / and the produced hydrogen are heated.

[0073] The temperature in the reforming chamber is set at 280°-409°, and the temperature in the separation chamber is set at 400°-460°.

[0074] The difference between the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com