Preparation method of rock-salt mine structure Co-doped CdS diluted magnetic semiconductor nanoparticles

A technology of dilute magnetic semiconductors, nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

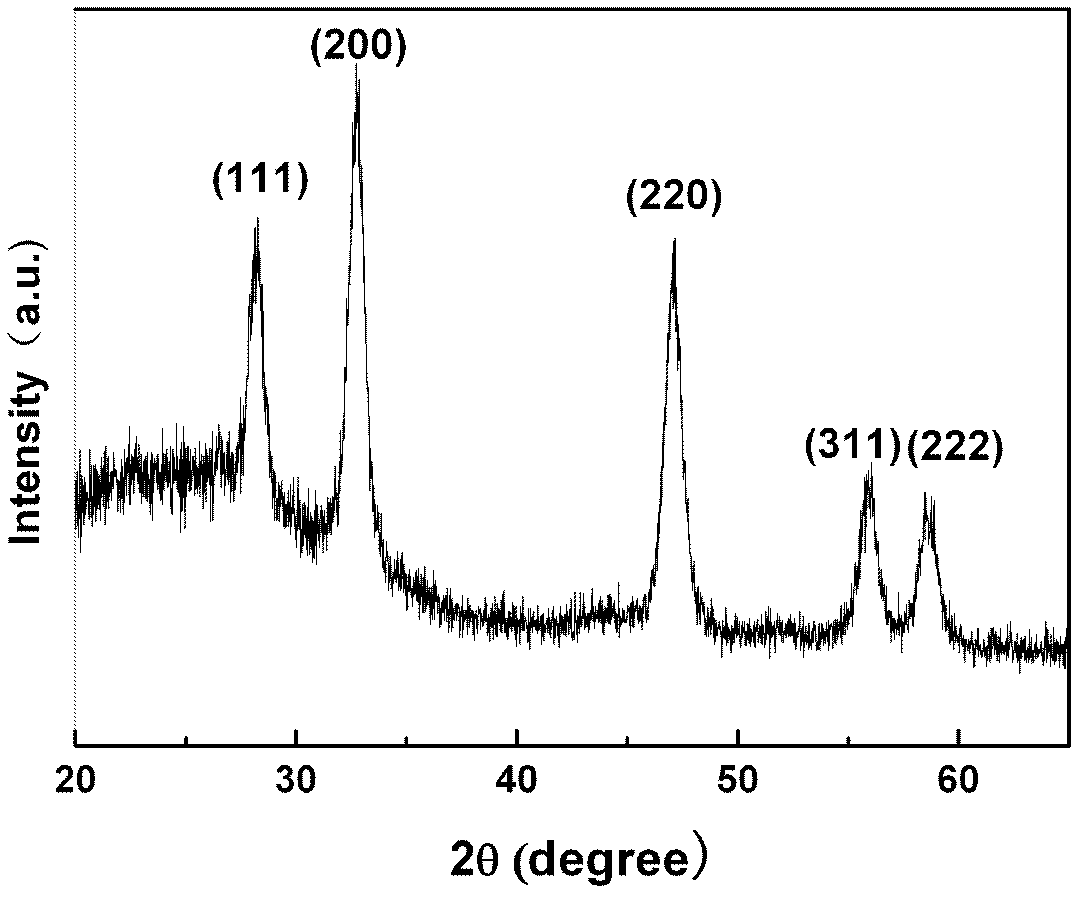

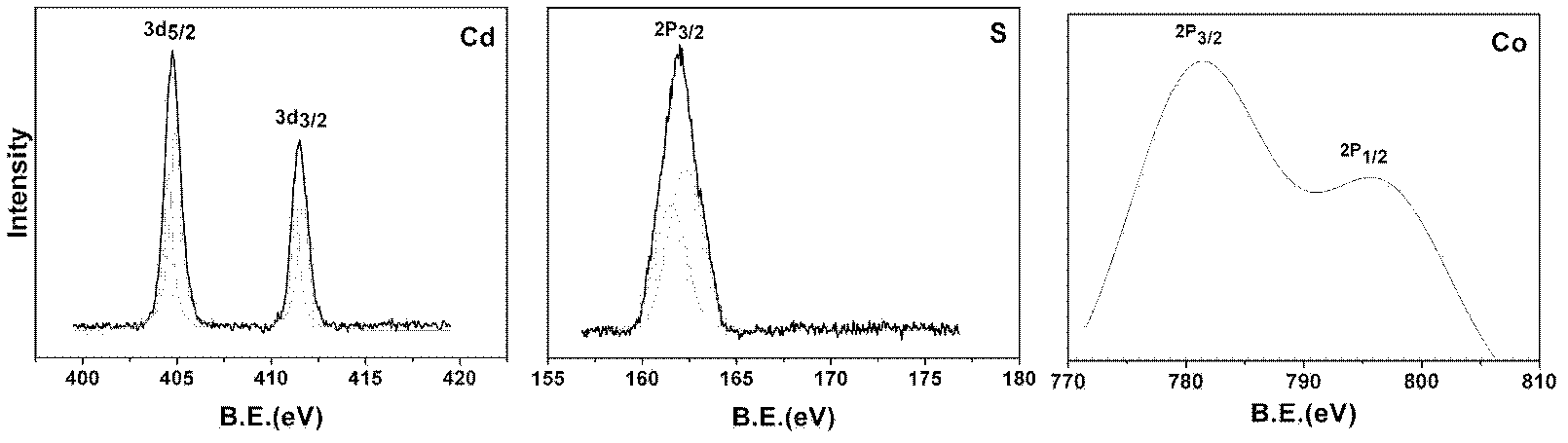

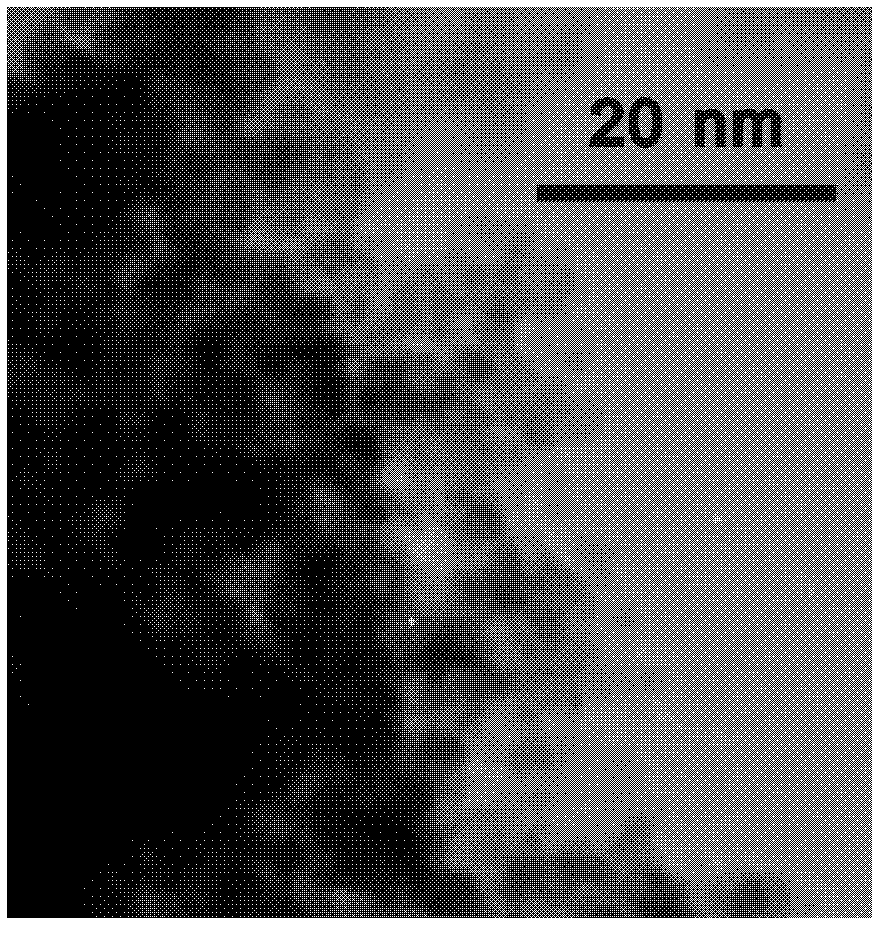

[0018] Example 1 The high-temperature and high-pressure treatment of Co-doped CdS with a doping concentration of 0.1441% atomic ratio

[0019] Co-doped CdS nanopowders with zinc blende structure were pressed into flakes with a diameter of 3 mm and a thickness of 1 mm. Put the pressed flakes into the reaction chamber of the six-sided top press. Adjust the pressure and temperature values so that the temperature reaches 600°C, the pressure reaches 5GPa, and the holding time reaches 30 minutes. After 30 minutes, the sample is cooled to room temperature and the pressure is released to obtain Co-doped CdS dilute magnetic semiconductor nanoparticles with a rock salt ore structure. composed of bulk materials.

[0020] Adjust the pressure, temperature, and holding time to 6GPa, 700°C, 40 minutes or 7GPa, 800°C, 50 minutes, respectively, and obtain two groups of bulk materials composed of Co-doped CdS dilute magnetic semiconductor nanoparticles with a rock-salt structure.

[0021] A...

Embodiment 2

[0022] Example 2 The high-temperature and high-pressure treatment of Co-doped CdS with a doping concentration of 0.1365% atomic ratio

[0023] Co-doped CdS nanopowders with zinc blende structure were pressed into flakes with a diameter of 3 mm and a thickness of 1 mm. Put the pressed flakes into the reaction chamber of the six-sided top press. Adjust the pressure and temperature values so that the temperature reaches 600°C, the pressure reaches 5GPa, and the pressure holding time reaches 30 minutes. After 30 minutes, the sample is cooled to room temperature and the pressure is released. A bulk material composed of Co-doped CdS dilute magnetic semiconductor nanoparticles with a rock-salt structure was obtained.

[0024] The pressure, temperature and pressure holding time were adjusted to 6GPa, 700°C, 40 minutes and 7GPa, 800°C, 50 minutes, respectively, and two groups of bulk materials composed of Co-doped CdS dilute magnetic semiconductor nanoparticles with rock salt ore st...

Embodiment 3

[0026] Example 3 High-temperature and high-pressure treatment of Co-doped CdS with a doping concentration of 0.1466% atomic ratio

[0027] Co-doped CdS nanopowders with zinc blende structure were pressed into flakes with a diameter of 3 mm and a thickness of 1 mm. Put the pressed flakes into the reaction chamber of the six-sided top press. Adjust the pressure and temperature values so that the temperature reaches 600°C, the pressure reaches 5GPa, and the pressure holding time reaches 30 minutes. After 30 minutes, the sample is cooled to room temperature and the pressure is released. A bulk material composed of Co-doped CdS dilute magnetic semiconductor nanoparticles with a rock-salt structure was obtained.

[0028] The pressure, temperature and pressure holding time were adjusted to 6GPa, 700°C, 40 minutes and 7GPa, 800°C, 50 minutes, respectively, and two groups of bulk materials composed of Co-doped CdS dilute magnetic semiconductor nanoparticles with rock salt ore struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com