Composition of hydrogenated segmented copolymer elastomer-nylon 6

A technology of hydrogenated block and copolymer, applied in the composition of hydrogenated block copolymer elastomer and nylon 6, and the composition of hydrogenated block copolymer elastomer-nylon 6, can solve the problem of poor compatibility, It is difficult to achieve modification and other problems to achieve the effect of good processing fluidity, high strength and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

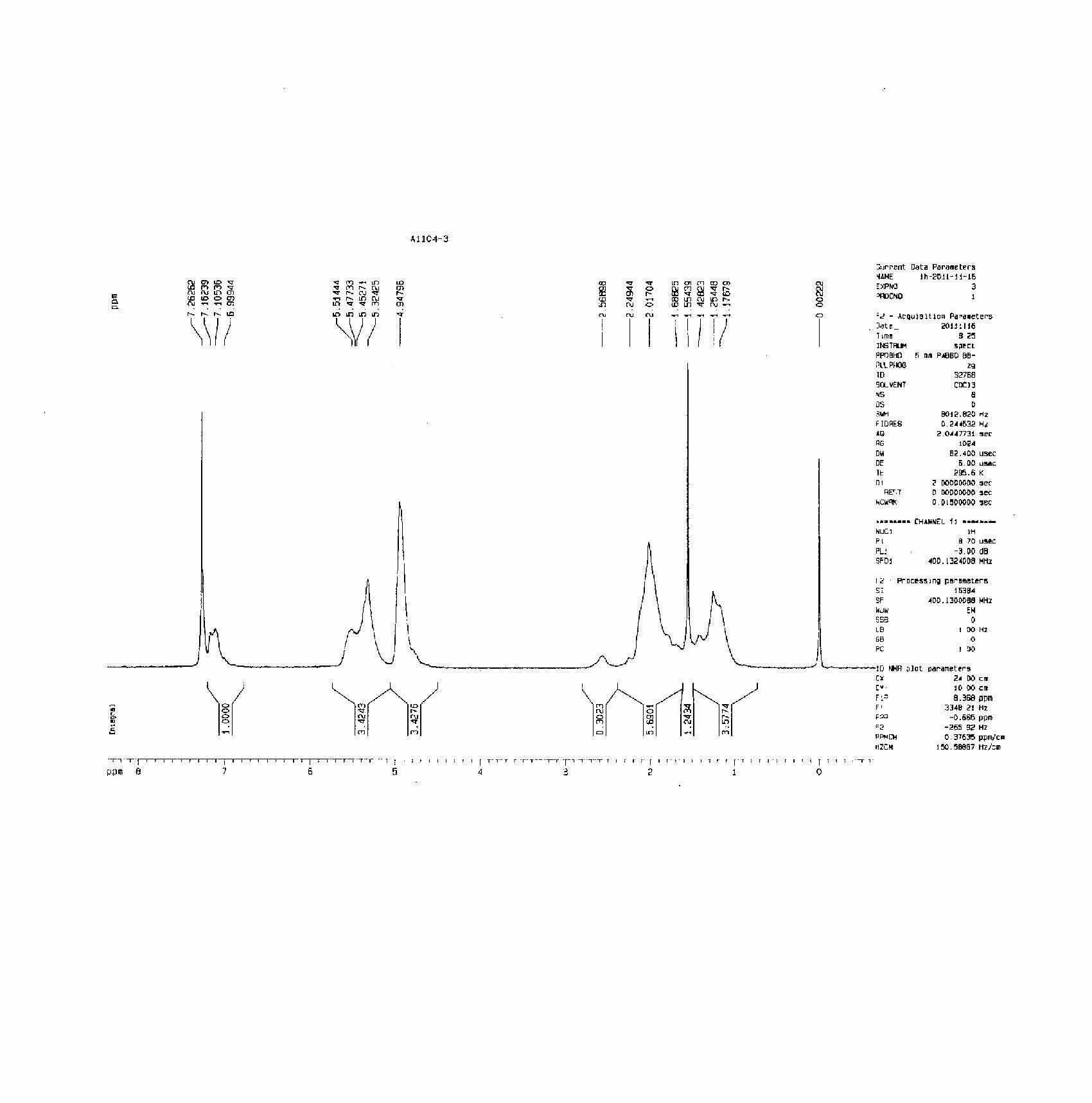

[0030] Synthesis of Hydrogenated Styrene-Butadiene Block Copolymer

[0031]Add 3 liters of non-polar mixed solution to the 5L stainless steel polymerization kettle purified by nitrogen, wherein 90% cyclohexane, 10% hexane (accounting for the mass percent of the mixed solution), 2mmol tetrahydrofuran, and the polymerization kettle is warming up to 45%. -50℃, add 12ml of initiator n-butyllithium (n-butyllithium concentration 0.4mol / l), stir for 2-3 minutes, add 45g of styrene for polymerization, after 30 minutes of reaction, add 2ml of tetrahydrofurfuryl alcohol ethyl ether and The mixture of 90 grams of styrene and 24 grams of butadiene was added to the polymerization kettle to carry out polymerization reaction. After 20 minutes of reaction, 96 grams of butadiene was added to carry out polymerization reaction. After adding 45 grams of styrene, the hydrogenation reaction was carried out after 30 minutes of reaction. First, 72 grams of co-catalyst dimethyl phthalate was added to ...

Embodiment 2

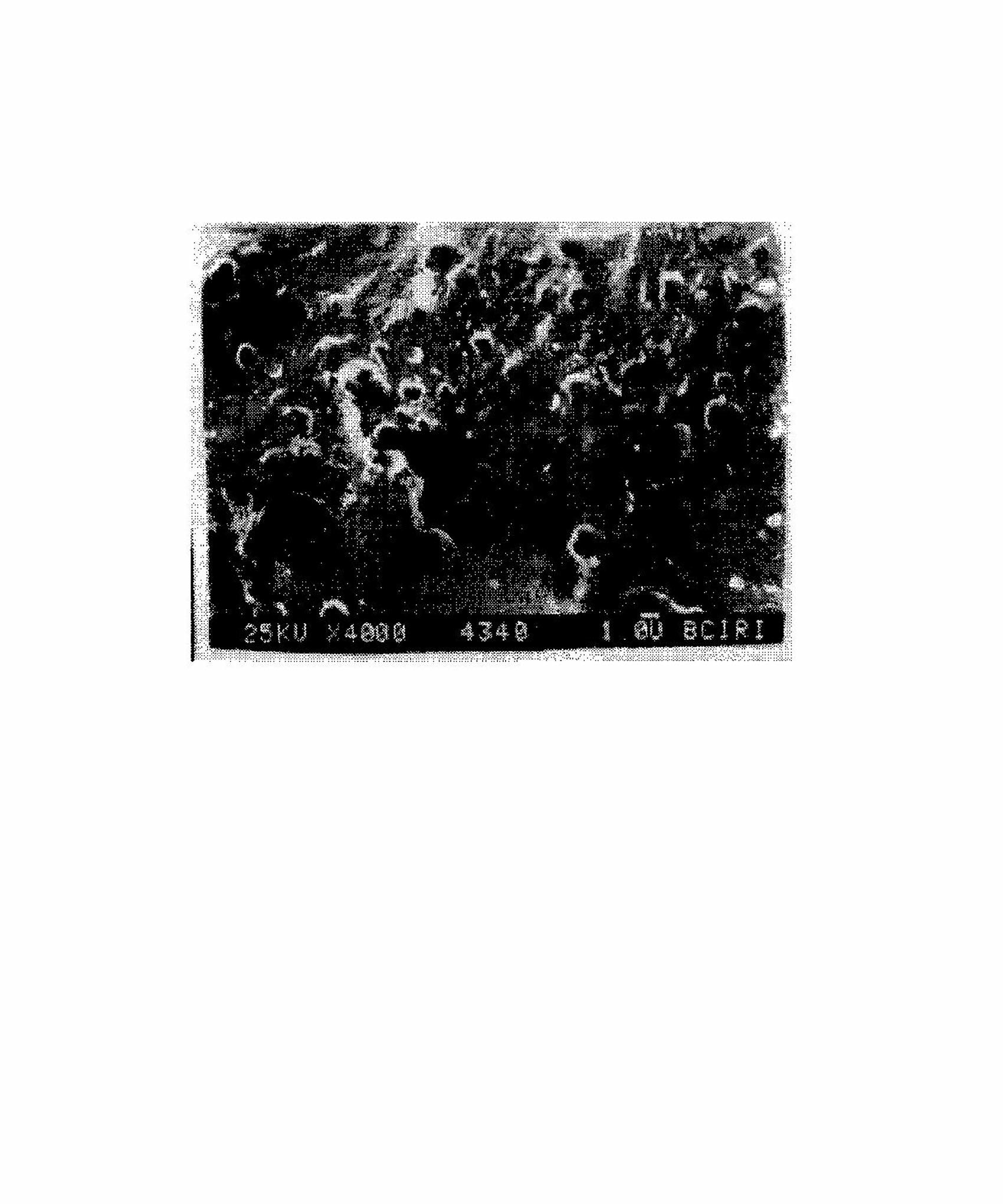

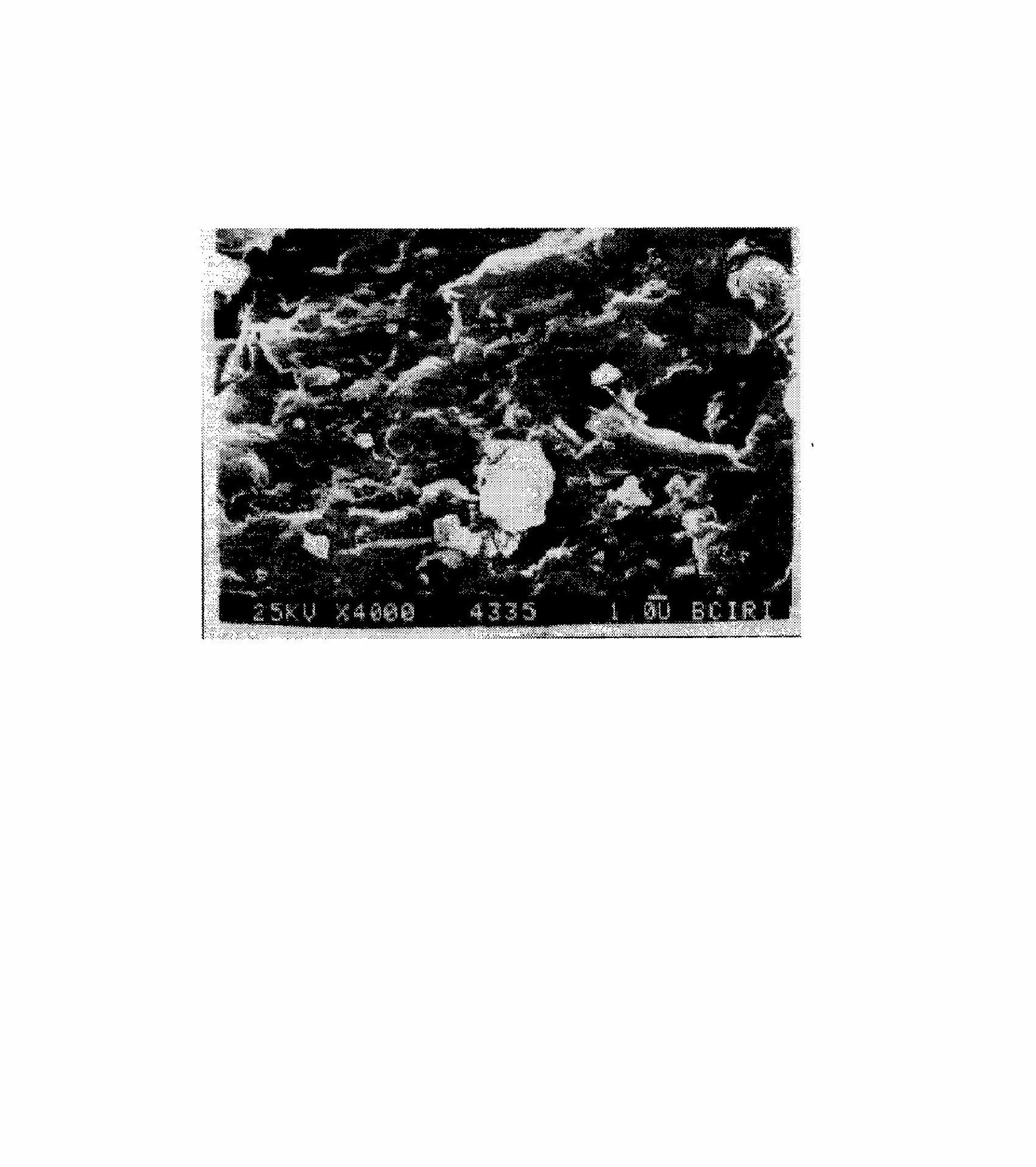

[0033] Set the filling oil (kinematic viscosity (40°C) to 32mm 2 / s) and hydrogenated styrene-butadiene block copolymer SEBS are mixed evenly. After the hydrogenated styrene-butadiene block copolymer SEBS fully absorbs the filler oil, add nylon 6 (melt flow rate is 1.2 g / 10min) and auxiliary EBS, mixed evenly in a high-speed stirring pot, and then granulated by twin-screw, the granules were made into test samples for scanning electron microscopy (ie SEM, such as figure 2 ) to test the dispersion, water absorption and physical and mechanical properties of SEBS in nylon 6. The parts by weight of each component are as follows:

[0034] 12 parts of hydrogenated styrene-butadiene block copolymer;

[0035] Nylon 6 77.5 parts

[0036] 16 parts filler oil

[0037] 0.5 servings of EBS.

[0038] Table 1 Sample test performance results

[0039] Tensile strength, MPa Bending strength, MPa Notched impact strength, KJ / m 2 Water absorption, % 52.1 70 88.8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com