Liquid fermentation method for improving yield of cordyceps sinensis polysaccharide by utilizing expansin

A technology of liquid fermentation and protein expansion, which is applied in the direction of using fungi, methods based on microorganisms, fermentation, etc., can solve the problems of few reports on protein expansion, achieve good industrial application prospects, promote and improve fermentation production, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation steps of the expansin solution described in the examples are as follows:

[0038] Soybean (Glycine max L.Merr.CV.M40; purchased from Jinan Weili Seed Industry Co., Ltd.) or cucumber (Cucumis sativus L.CV. Jinnian No.6; purchased from Jinan Weili Seed Industry Co., Ltd.) seeds were subjected to 0.1 wt% HgCl 2 Disinfect for 5 minutes, rinse with running water for 6 hours, then plant in wet vermiculite, and culture in dark at 27°C for 5 days. Cut off the top 3-4cm of the hypocotyl of the seedlings, that is, about 100g of the growth area, pre-cool in a -20°C refrigerator for 0.5h, add a homogenization buffer pre-cooled to 4°C, and after high-speed homogenization, filter with a 70μm nylon mesh. Wash the filter residue with homogenization buffer, then add the filter residue to the homogenization buffer, and stand at room temperature for 2 hours to obtain a standing solution; add the extract to the standing solution, extract at 4°C for 48 hours, filter, and th...

Embodiment 1

[0051] A liquid fermentation method for improving the yield of Cordyceps polysaccharide by utilizing expansin, comprising the following steps:

[0052] (1) Inoculate the strain of Cordyceps militaris (CGMCC No.5.699) into PD liquid fermentation medium, and carry out activation culture. Cultivate for 96 hours, then transfer the inoculum to the seed fermentation medium according to the volume percentage of 15%, and carry out seed cultivation. The seed cultivation conditions are: temperature 25°C, shaker cultivation for 3 days, to obtain seed liquid;

[0053] (2) Inoculate the seed solution prepared in step (1) in a liquid fermentation medium at a volume ratio of 10%, and carry out liquid fermentation culture for 1 day at a temperature of 25° C., and then add the expansin solution to increase the concentration of the expansin 0.15mg / mL, then continue to cultivate for 9 days, and centrifuge for 10min under the condition of 15000r / min to obtain Cordyceps militaris mycelium and ferm...

Embodiment 2

[0071] The liquid fermentation method as described in Example 1, the difference is that in step (2), under the condition of a temperature of 25°C, the liquid fermentation culture was carried out for 3 days, and then the expansin solution was added to make the concentration of the expansin 0.5 mg / mL, and then continue to culture for 7 days,

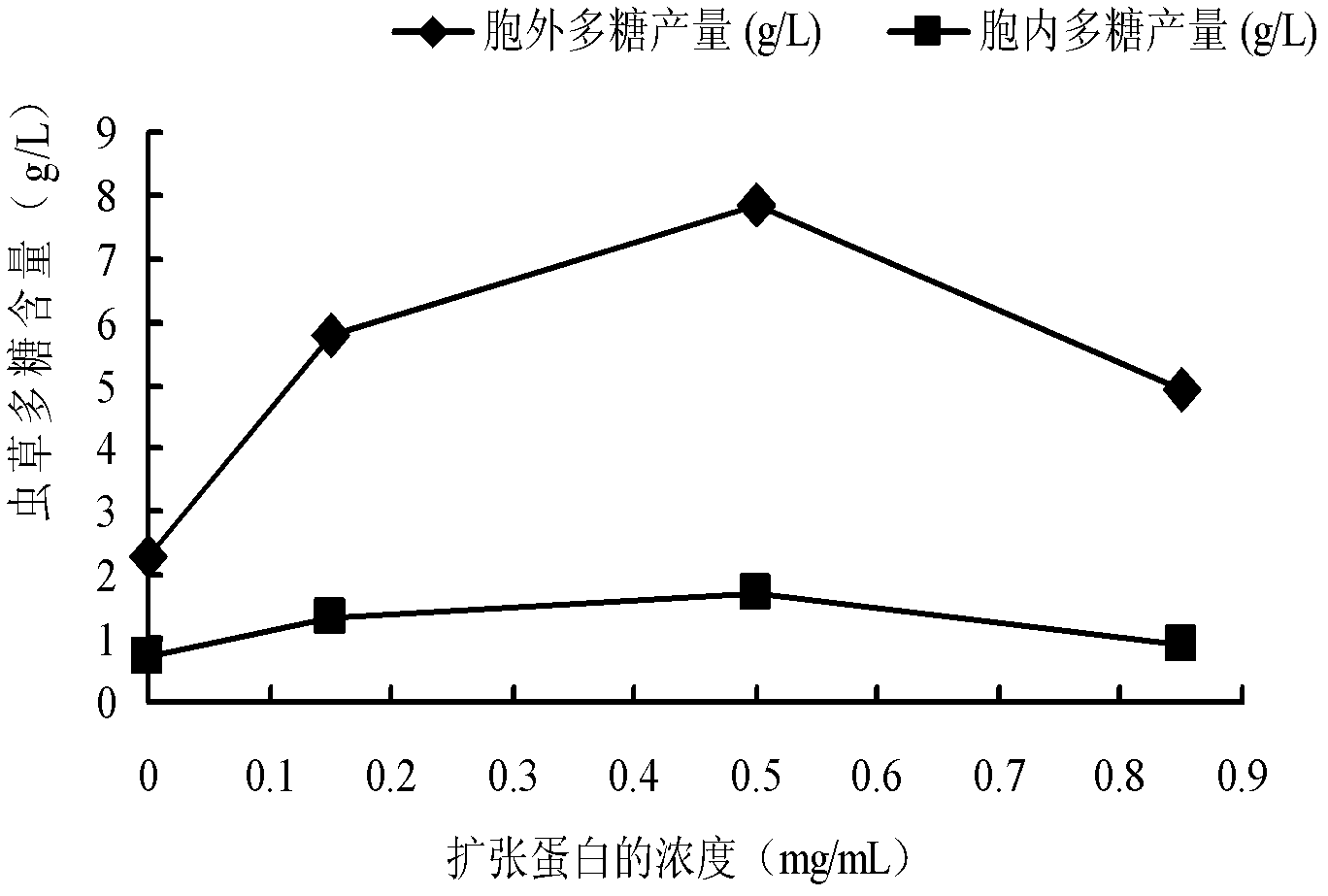

[0072] After detection and calculation, each milliliter of fermentation broth contains 7.83 mg of exopolysaccharide of Cordyceps militaris, that is, 7.83 g of exopolysaccharide per liter of fermentation broth; 260.15 mg of intracellular polysaccharide of Cordyceps militaris is contained in each gram of mycelium (dry weight). That is, the mycelia produced by each liter of fermentation broth contains 1.73g of intracellular polysaccharide of Cordyceps militaris. The result is as figure 1 shown.

[0073] Therefore, the total yield of Cordyceps polysaccharide is 7.83+1.73=9.56g per liter of fermentation broth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com