Hot-rolled H-steel for low temperature-resistance structure and preparation method for hot-rolled H-steel

A technology for structural and H-shaped steel, which is applied in the field of metallurgy, low-temperature resistant low-alloy high-strength structural steel, and can solve problems such as low nitrogen, oxygen content, increased cost, and infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

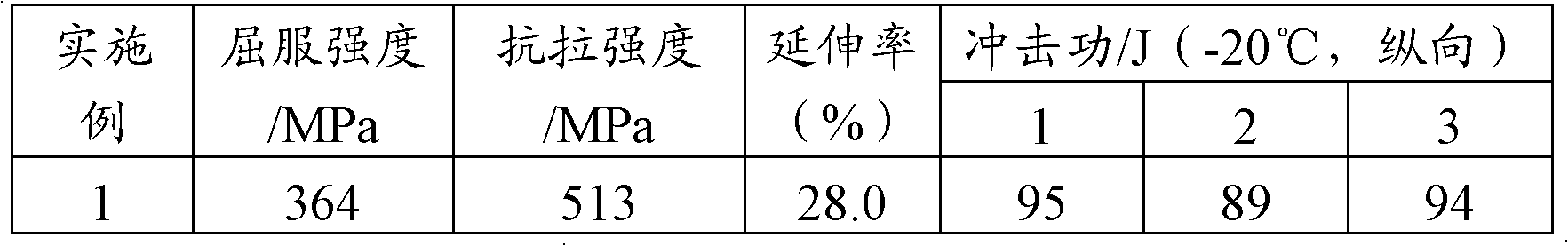

Examples

Embodiment

[0023] The process route is:

[0024] Hot metal pre-desulfurization→converter smelting→LF refining→full-protection continuous casting of special-shaped billet→1-3 rolling mill arrangement type production line rolling→inspection and storage.

[0025] The main technological measures of the preparation method:

[0026] (1) The molten iron arrives at the desulfurization station, and the sulfur content in the molten iron is guaranteed to be ≤0.010wt% after desulfurization.

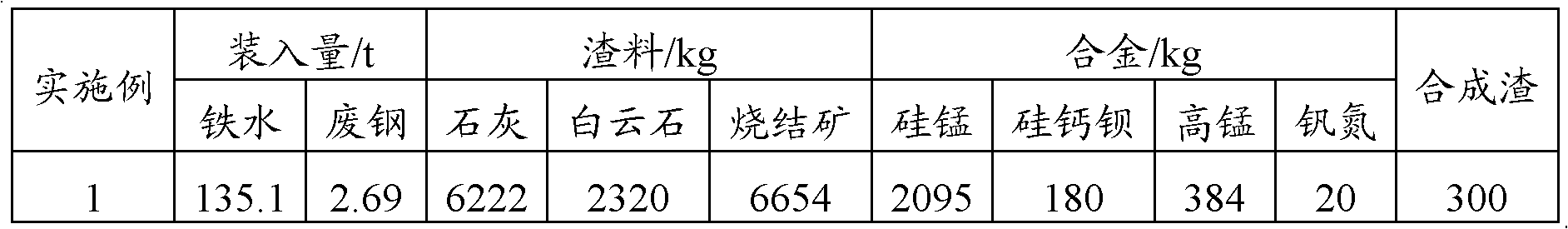

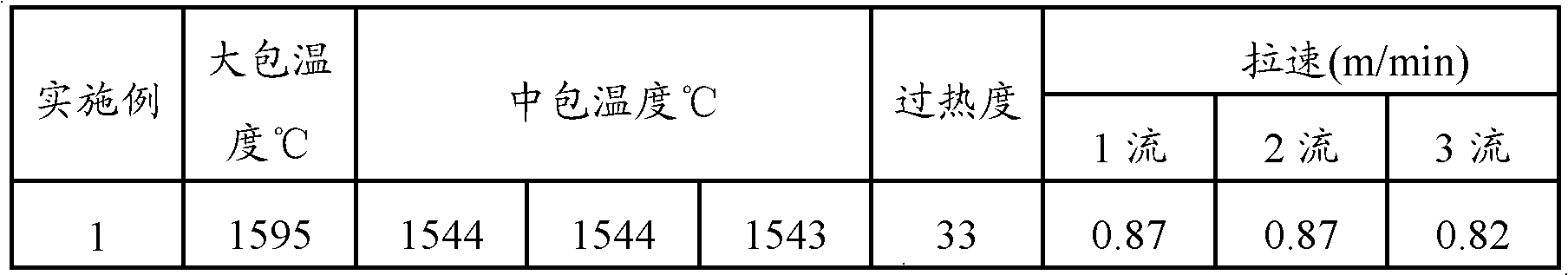

[0027] (2) Converter smelting: The raw materials entering the furnace must meet the following requirements: the sulfur content of molten iron is ≤0.010wt%; the operation with a large amount of slag and low gun position is adopted, and the slag is divided into two batches during the blowing process (the first batch adds 2 / 3 slag ) is added, and the slag is melted and thoroughly melted throughout the process. The ladle adopts a red net ladle with good bottom blowing, and the baking temperature is ≥800°C. Alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com