Cable stratum tester

A formation tester and cable technology, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve problems such as inability to adapt to various formation conditions, unfavorable disassembly, difficult maintenance, etc., to improve sampling accuracy and sampling efficiency, Ease of assembly and maintenance, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

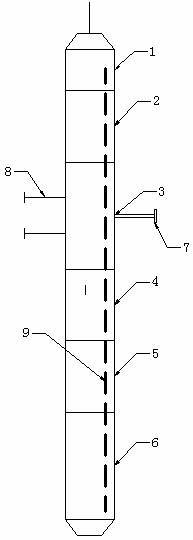

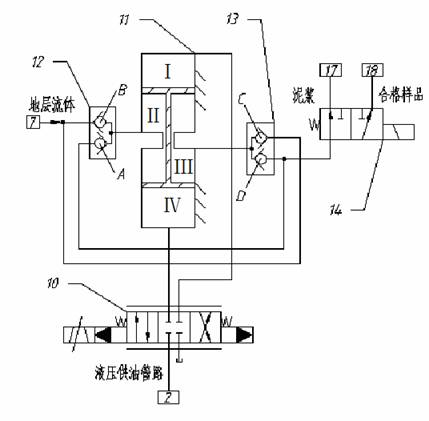

[0033] see figure 1 with figure 2 , a cable formation tester, including a probe and a pressure measurement module 3, a sampling cylinder module 6, a hydraulic power module 2, a pump extraction module 4, an electronic control module 1, a power supply module for supplying power to each module, and a common The pipeline 9, the probe and the pressure measurement module 3 include a retractable pusher 8, a sampling probe 7 and a pressure sensor. The sampling probe 7 and the pusher 8 are arranged opposite to each other, and can be supported on the inner wall of the wellbore 17, so that the cable formation The main body of the detector is fixed at the predetermined depth of the wellbore 17, and the formation fluid to be measured enters the sample pipeline directly through the sampling probe 7, and the pressure sensor measures the pressure of the fluid entering the sampling probe 7, and transmits the detection signal to the electronic control module 1 in real time. The power module 2...

Embodiment 2

[0045] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

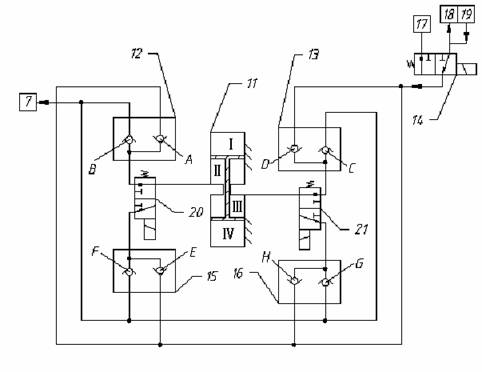

[0046] In this example, see image 3 , the pump exhaust module 4 also includes another set of one-way valve group, which is also a bridge circuit composed of four one-way valves, specifically one-way valve E, one-way valve F, one-way valve G and one-way valve H is connected sequentially, wherein the one-way valve G and the one-way valve H are connected in series to form a primary injection fluid one-way valve 15, wherein the one-way valve F and the one-way valve E are connected in series and form a two-stage injection fluid one-way valve. The one-way valve 16, the one-way valve F and the one-way valve G are connected in reverse series, and the one-way valve H and the one-way valve E are also connected in reverse series, and the sampling probe 7 is simultaneously connected with the liquid outlet of the one-way valve F and The liquid outlet of the one-way va...

Embodiment 3

[0048] The technical solutions of this embodiment are basically the same as those of the foregoing embodiments, except that:

[0049] In this embodiment, the downhole fluid identification module includes a resistivity tester. The resistivity tester detects the resistivity of the formation fluid entering the sample pipeline. In the fluid pumping mode, when the detected resistivity of the original formation fluid meets After the sampling request, immediately enter the fluid sample sampling stage, and switch the liquid flow outlet of the two-position three-way solenoid valve 14 to inject the formation fluid in the sample pipeline into the PVT sampling cylinder 18 . By detecting the resistivity of the original formation fluid and referring to the system working standard value, the key step of switching the two-position three-way solenoid valve 14 from the fluid pumping mode stage is realized, and the formation fluid in the sample pipeline is injected into the PVT sampling cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com