Connecting structure of three-layer steel-plastic glass fiber composite pipe and connecting method thereof

A connection structure and layer composite technology, applied in the field of composite pipes, can solve problems such as water seepage, reduce maintenance costs, reduce operating cycle costs, and solve the effects of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

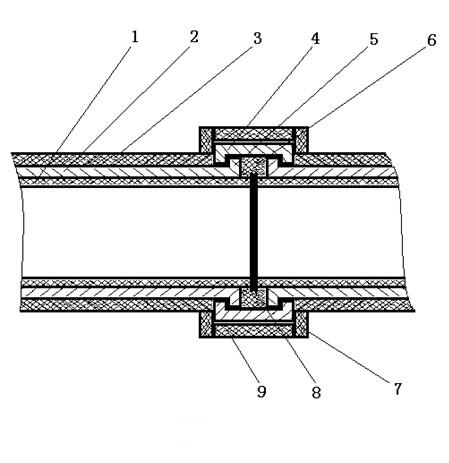

[0022] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

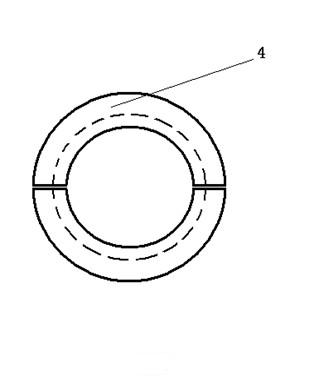

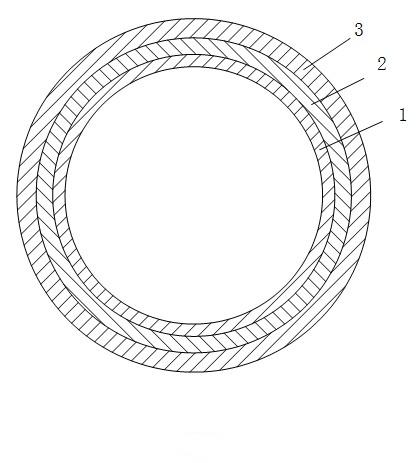

[0023] according to figure 1 and image 3 As shown, the structure and production method of the steel-plastic glass fiber three-layer composite pipe need to be introduced first. The structure is plastic pipe 1, steel pipe 2, and glass fiber resin pipe 3 from the inside to the outside. The production method is: the production method of the steel-plastic glass fiber three-layer composite pipe, and the steps are as follows:

[0024] 1) First, insert the plastic pipe into the steel pipe to form a steel-plastic composite pipe; fix the steel-plastic composite pipe on the rotating shaft of the winding machine to make it rotate at a uniform speed;

[0025] 2) Start the resin-impregnated glass fiber feeding device, immerse m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com