Resonance excitation method of micro-cantilever sensor

A technology of micro-cantilever beam and resonance excitation, which is applied in the direction of using electric/magnetic devices to transmit sensing components, can solve the problems of unable to achieve probe resonance excitation, unable to reach resonance frequency, unable to perform dynamic detection, etc., and achieve easy and precise control. , The effect of easy production and processing, high-speed real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

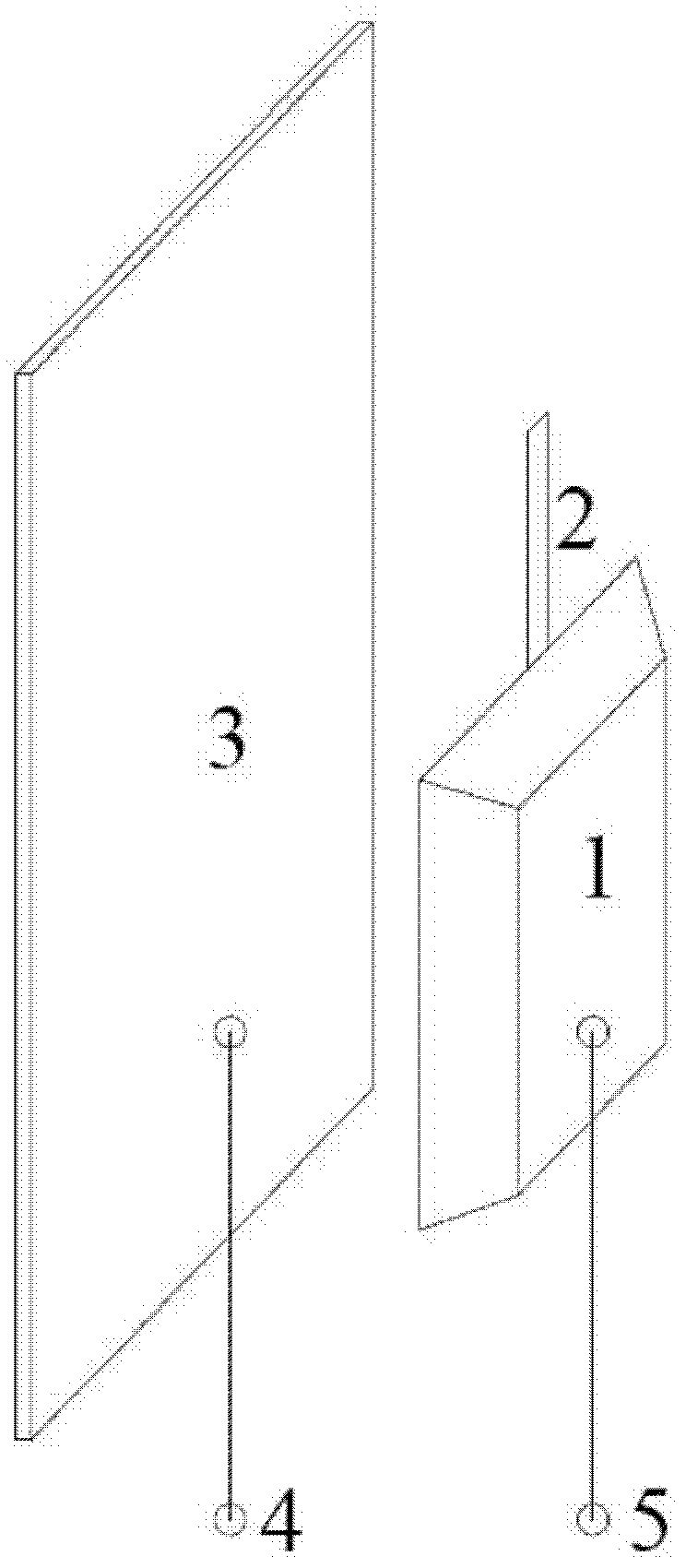

[0025] A microcantilever sensor, such as figure 1 As shown, the micro-cantilever sensor comprises a micro-cantilever base (1) of n-type doped silicon material and a metal electrode (3) placed parallel to the micro-cantilever base; one end of the micro-cantilever base (1) is provided with A needle-free probe (2) of the same material integrated with the base of the micro-cantilever beam, the base of the micro-cantilever beam (1) and the metal electrode (3) are respectively provided with a pulse electric signal access lead (5) and a DC bias connection. Insert the lead wire (4).

[0026] The dimensions of the tipless probe of the microcantilever are 100 microns in length, 20 microns in width, and 1 micron in thickness. The distance between the base of the micro-cantilever beam and the metal electrode is 100 microns.

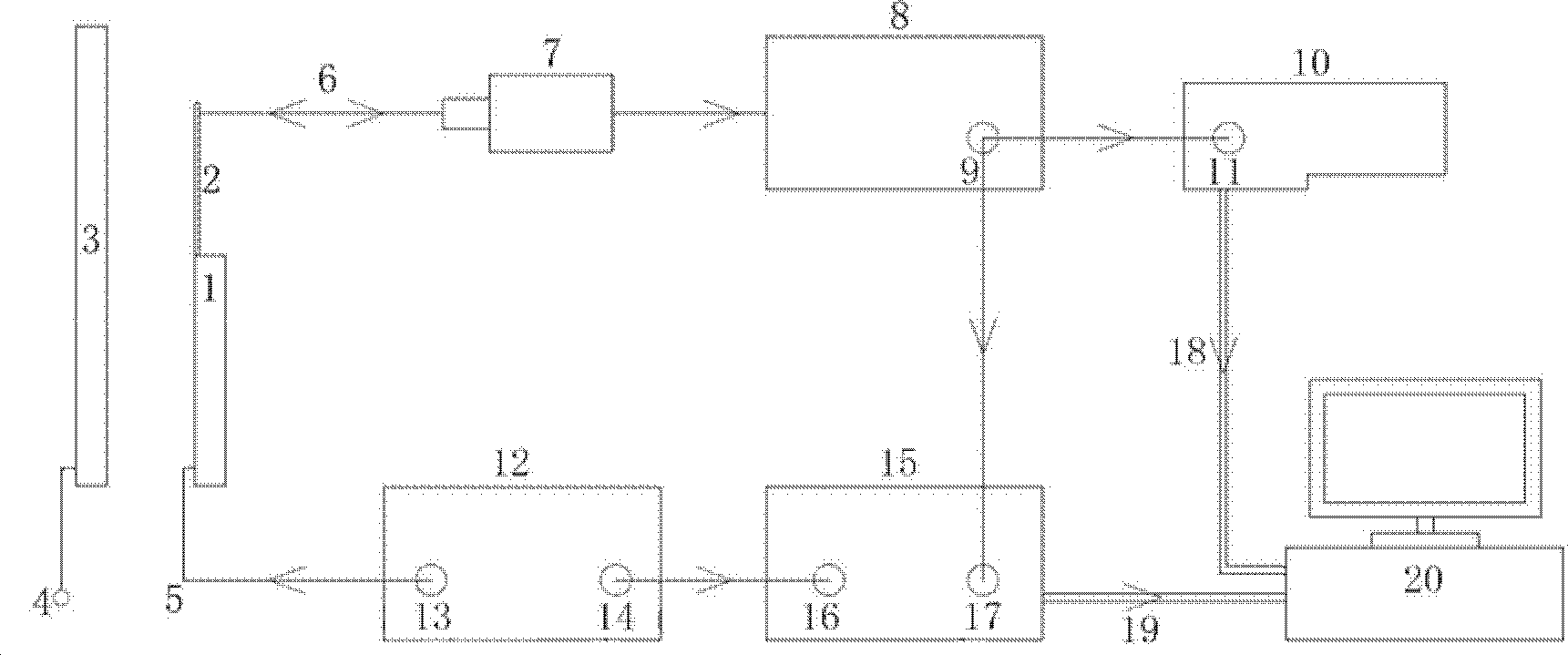

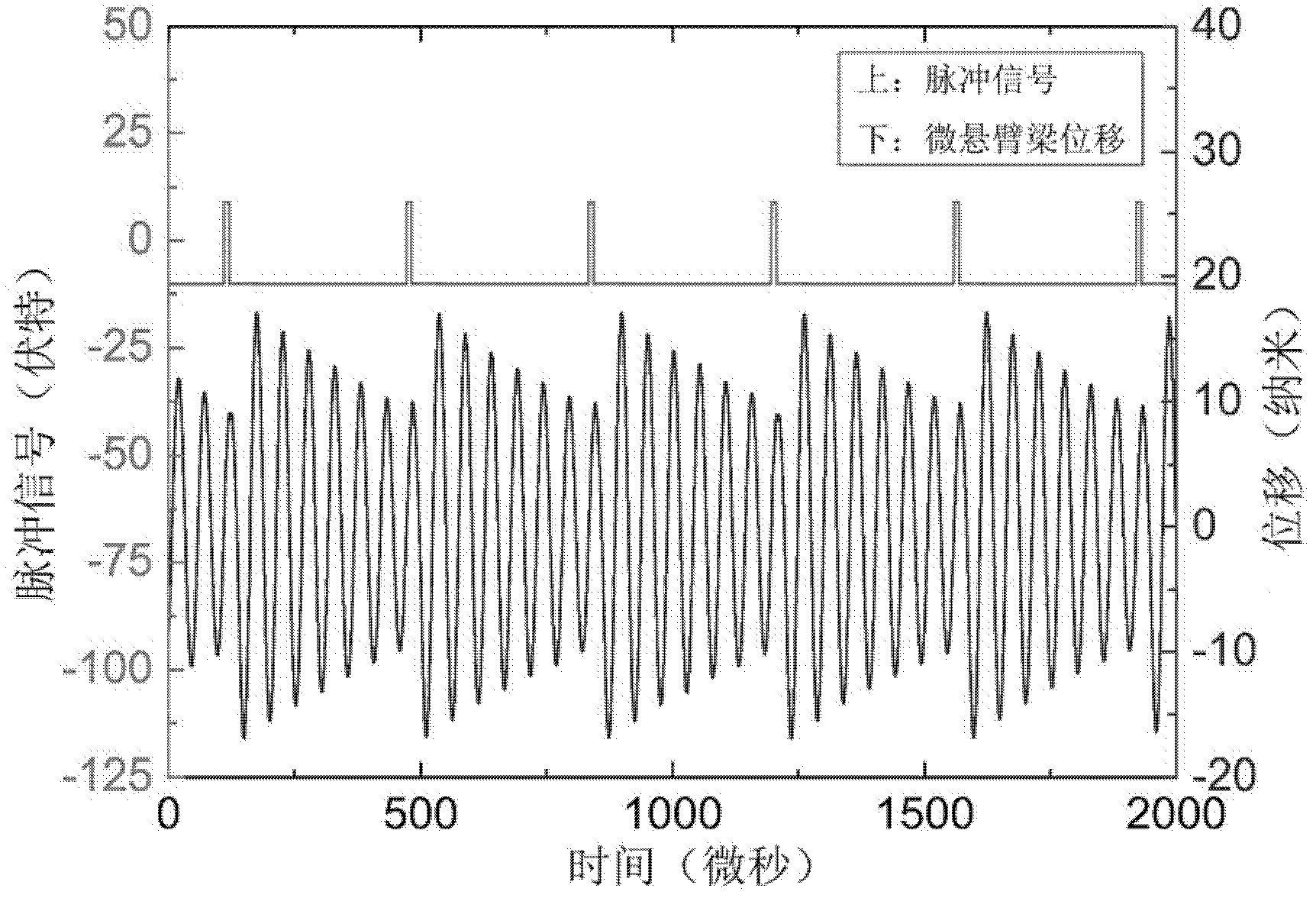

[0027] The resonant excitation method of the above-mentioned micro-cantilever beam sensor is as follows: the signal generator provides a DC voltage signal with an ...

Embodiment 2

[0029] A method for resonance excitation of a micro-cantilever sensor, the structure of the micro-cantilever sensor and its resonance excitation method are the same as those in Embodiment 1, the difference being that:

[0030] The size of the tipless probe of the microcantilever is 200 microns in length, 30 microns in width, and 1.5 microns in thickness. The distance between the base of the micro-cantilever beam and the metal electrode is 500 microns.

[0031] The signal generator provides a DC voltage signal with an amplitude of 8 volts to the metal electrode through the wire on the metal electrode, and at the same time, the signal generator provides a needle-free probe with an amplitude of 8 volts to the micro-cantilever beam through the wire on the base of the micro-cantilever beam. volts, a pulse electrical signal with a bias voltage of 0 volts, and the frequency of the pulse signal is 1 / 7 times the resonance frequency of the micro-cantilever beam probe.

Embodiment 3

[0033] A method for resonance excitation of a micro-cantilever sensor, the structure of the micro-cantilever sensor and its resonance excitation method are the same as those in Embodiment 1, the difference being that:

[0034] The dimensions of the tipless probe of the microcantilever are 300 microns in length, 40 microns in width, and 2 microns in thickness. The distance between the base of the micro-cantilever beam and the metal electrode is 1000 microns.

[0035] The signal generator provides a DC voltage signal with an amplitude of 10 volts to the metal electrode through the wire on the metal electrode, and at the same time, the signal generator provides the micro-cantilever needleless probe with an amplitude of 10 V through the wire on the base of the micro-cantilever beam. volts, a pulse electrical signal with a bias voltage of 0 volts, and the frequency of the pulse signal is 1 / 10 times the resonance frequency of the micro-cantilever beam probe.

[0036] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com