Precious metal ultramicroelectrode and preparation method thereof

A technology of ultra-micro electrodes and precious metals, applied in the field of electrochemistry, can solve the problems of difficult preparation, difficult preparation process, etc., and achieve the effect of overcoming the complexity of the preparation process, controllable size and shape, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

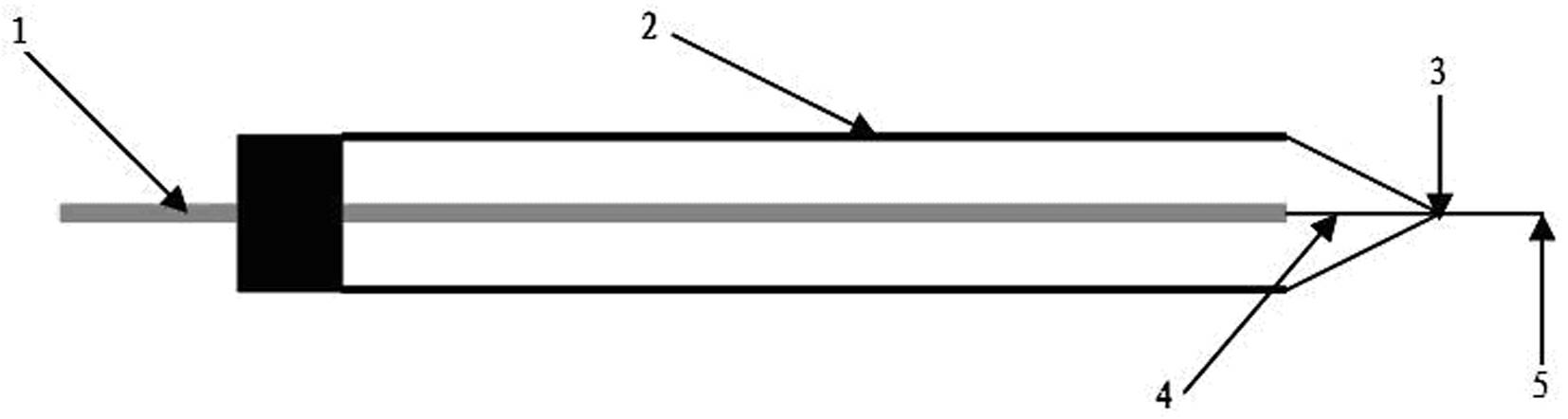

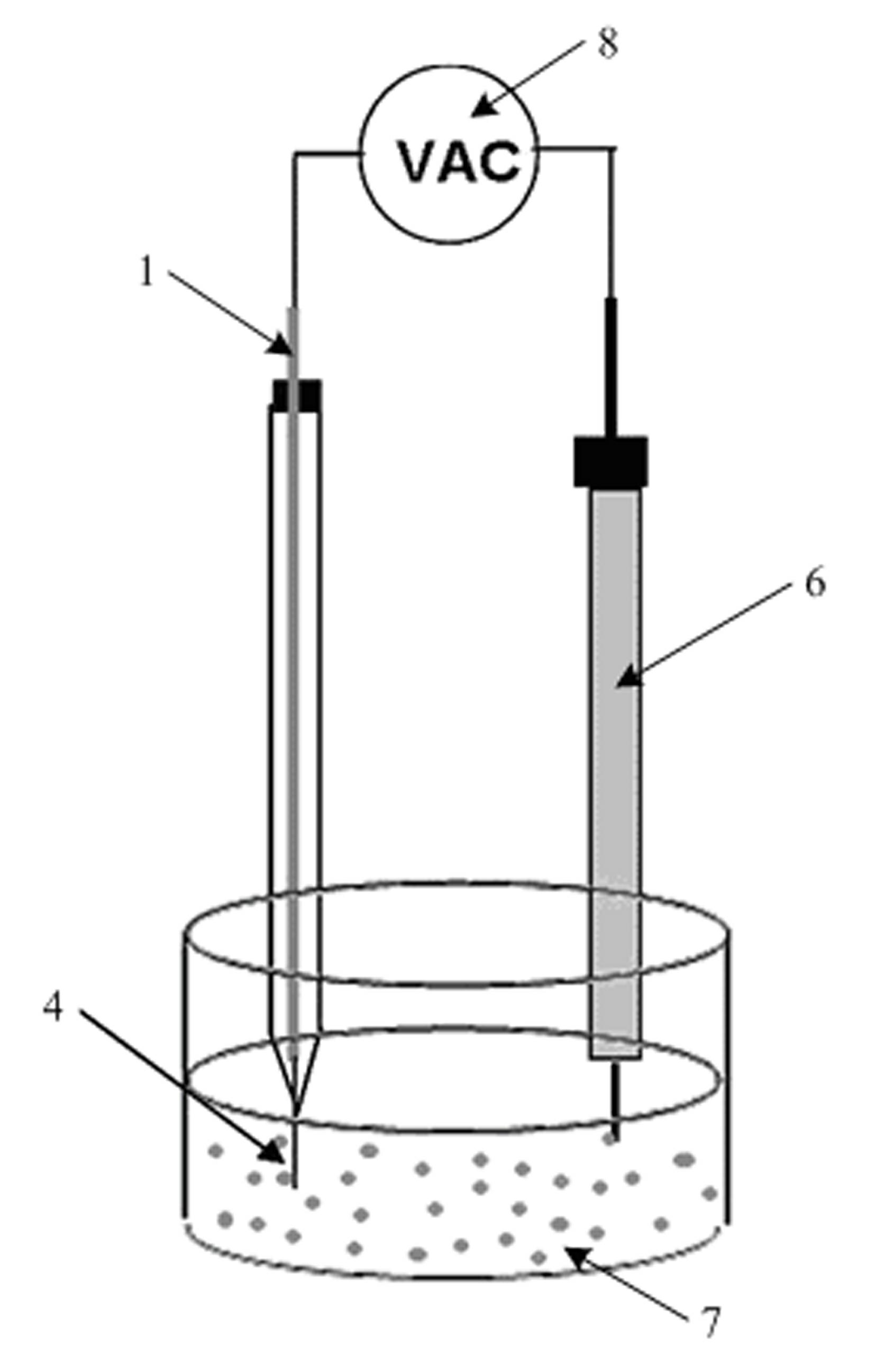

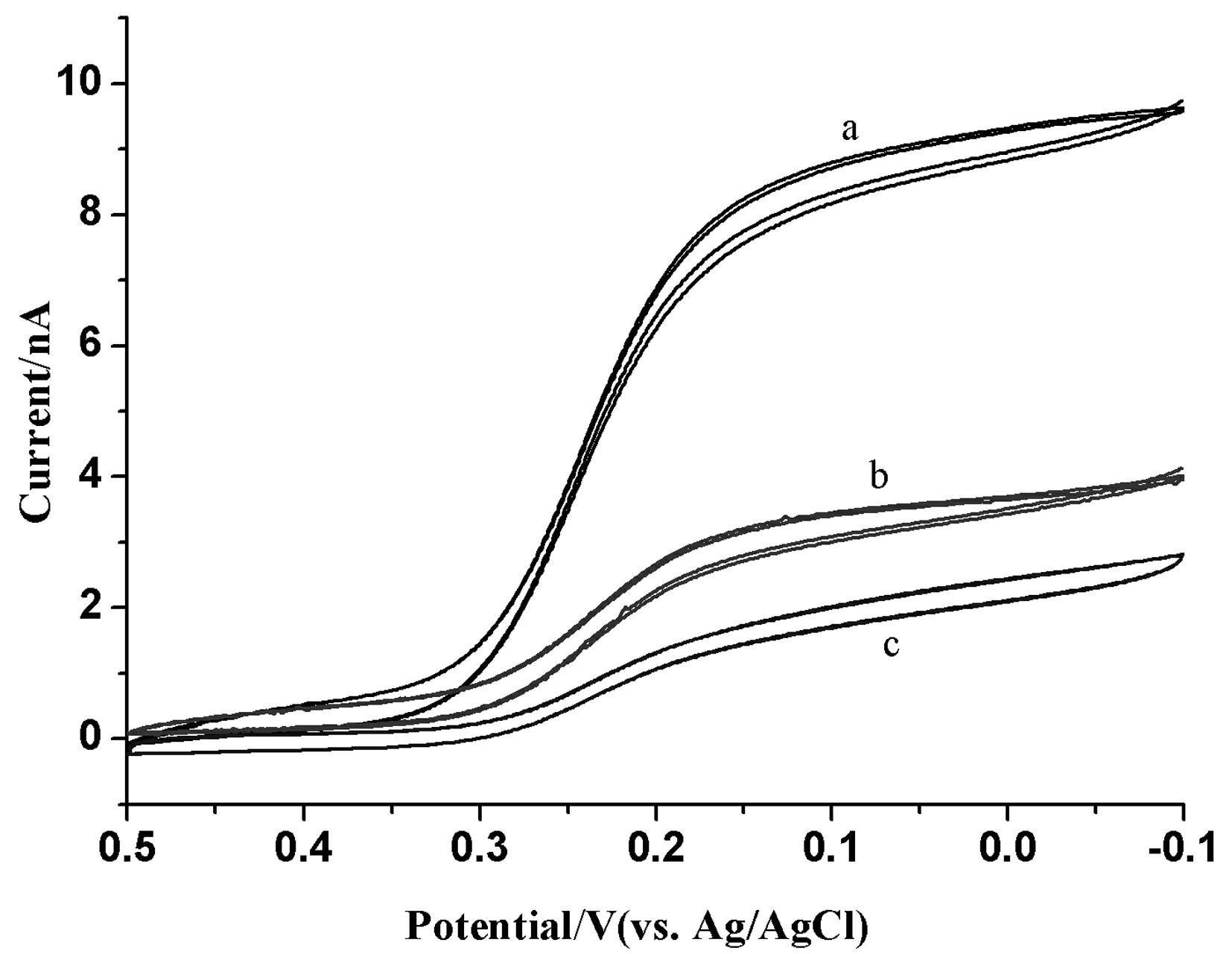

[0055] According to an embodiment of the present invention, a method for preparing a platinum ultramicroelectrode is provided. In this embodiment, platinum Pt is selected as the precious metal, and the preparation method of the platinum ultramicroelectrode is as follows:

[0056] Step 1: Drawing of the glass capillary, that is, select a clean glass capillary with an inner diameter of 0.58mm and an outer diameter of 1.0mm, and use a microtube drawing instrument to draw one end of the glass capillary at a heating index of 760 degrees. A tip with an inner diameter of 60 μm;

[0057] Step 2: Cut the copper wire with a diameter of 0.5mm into 10cm long sections, keep the copper wires straight for use; then cut the platinum wires with a diameter of 25μm into small sections with a length of about 2cm; One end of the wire is dipped in conductive silver glue, and one end of the above cut platinum wire is glued to the end of the copper wire dipped in conductive silver glue. After drying...

Embodiment 2

[0078]Different from the foregoing embodiments, in this embodiment, the preparation method of platinum ultramicroelectrodes is as follows:

[0079] Step 1: Drawing of the glass capillary, namely: select a clean glass capillary with an inner diameter of 0.54mm and an outer diameter of 0.8mm, and use a microtube drawing instrument to draw one end of the glass capillary at a heating index of 740 degrees. A tip with an inner diameter of 20 μm;

[0080] Step 2: Cut the copper wire with a diameter of 0.4mm into 8cm long pieces, keep the copper wire straight for later use; then cut the platinum wire with a diameter of 22μm into small sections with a length of about 1.8cm; One end of the copper wire is dipped in conductive silver glue, and one end of the above-mentioned cut platinum wire is glued to the end of the copper wire dipped in conductive silver glue. After drying in the air for 4 minutes, put it into an oven with a temperature of 95°C for baking. 12min, so that the conductiv...

Embodiment 3

[0100] Different from the foregoing embodiments, in this embodiment, the preparation method of platinum ultramicroelectrodes is as follows:

[0101] Step 1: Drawing of the glass capillary, that is, select a clean glass capillary with an inner diameter of 0.62mm and an outer diameter of 1.2mm, and use a microtube drawing instrument to draw one end of the glass capillary at a heating index of 780 degrees. A tip with an inner diameter of 100 μm;

[0102] Step 2: Cut the copper wire with a diameter of 0.6mm into small sections of 11cm long, keep the copper wire straight for use; then cut the platinum wire with a diameter of 28μm into small sections of about 2.2cm in length; One end of the copper wire is dipped in conductive silver glue, and one end of the above-mentioned cut platinum wire is glued to the end of the copper wire dipped in conductive silver glue. After drying in the air for 7 minutes, put it into an oven with a temperature of 120°C for baking. 20min to fully cure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com