Single vehicle debugging test stand and debugging method

A debugging method and a technology of a test bench, applied to measuring devices, instruments, measuring electronics, etc., can solve problems such as heavy workload, complicated changes, and complicated wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

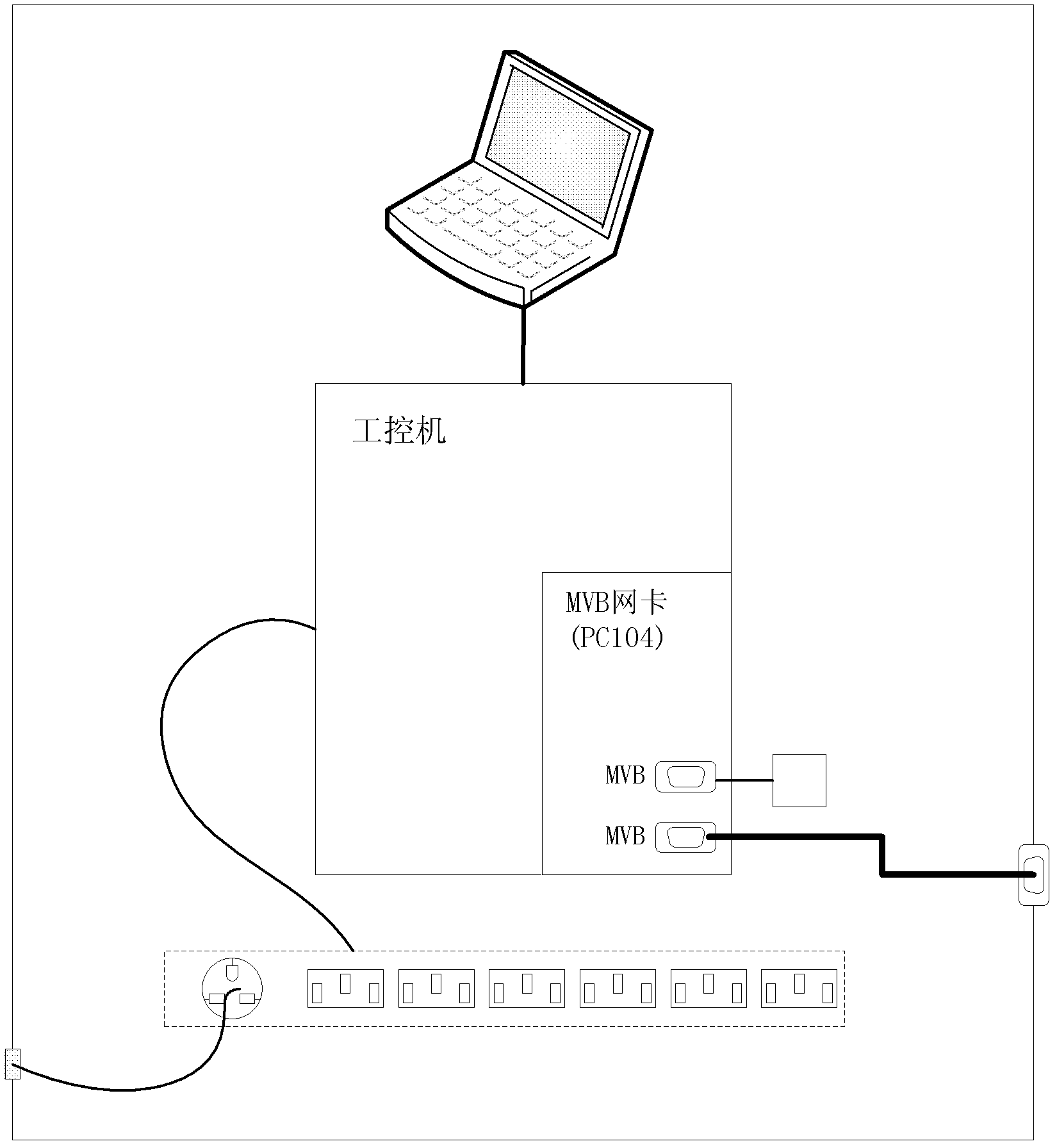

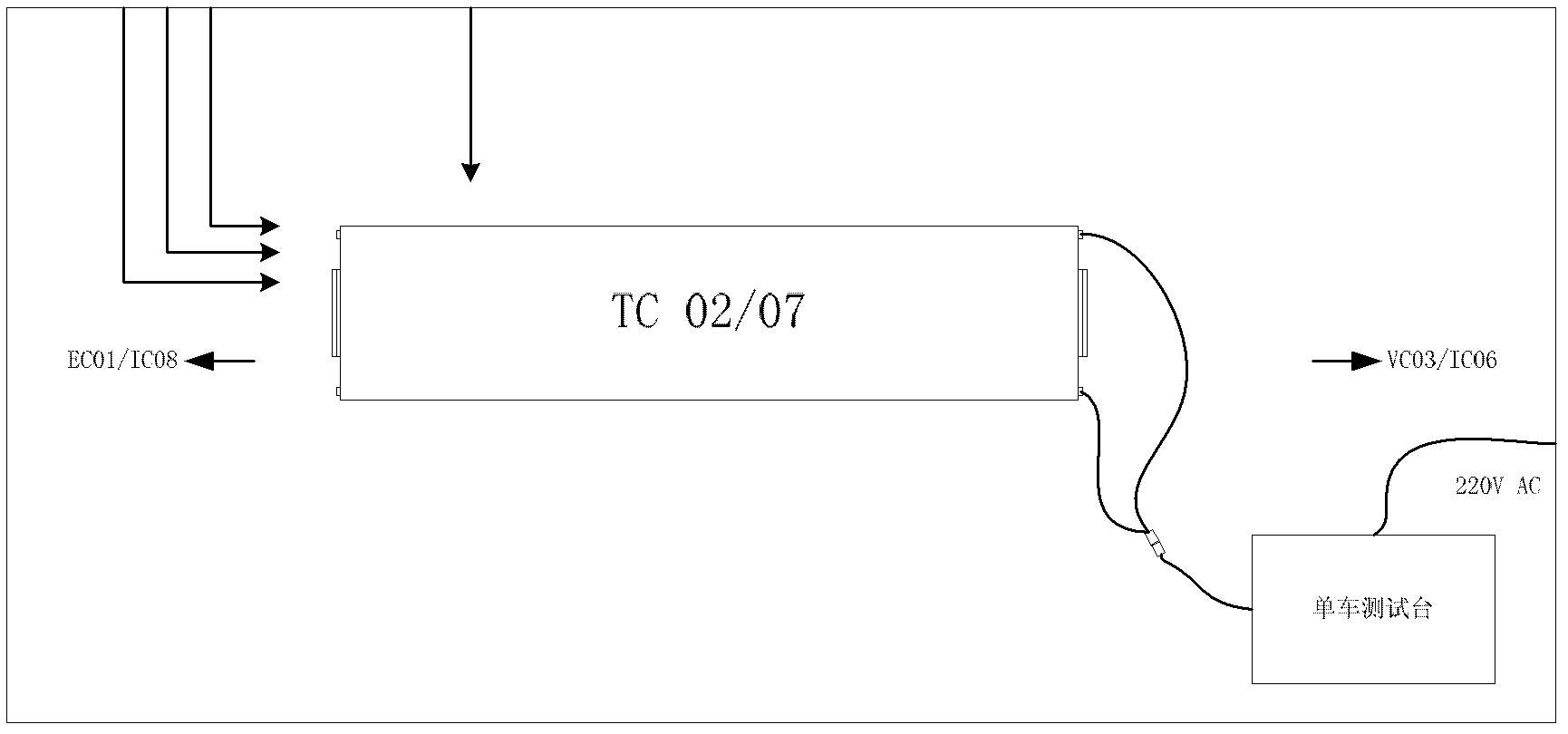

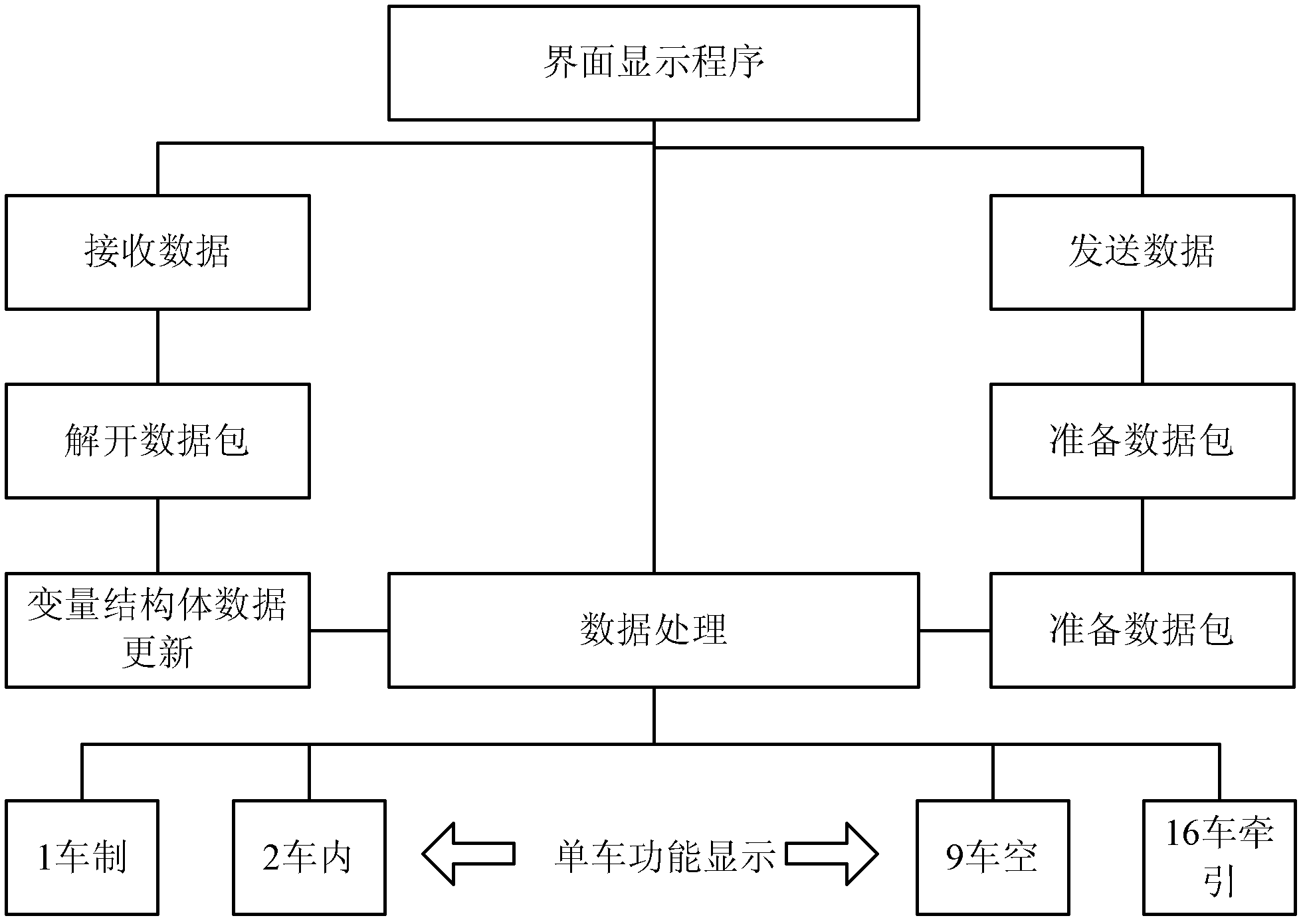

[0016] The present invention is to provide a single-vehicle debugging test bench with relatively simple structure, high test efficiency, accurate measurement results, and intuitive feedback results, and a debugging method adopted on the test bench. By using the TCN vehicle-mounted network technology, the electrical debugging and monitoring of single-vehicle trains can be realized. Partial function debugging of each subsystem. The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] In order to overcome the deficiencies of the existing test methods, the present invention utilizes vehicle-mounted network control technology and Ethernet communication technology to provide a train electrical debugging method. This method does not need to build a complicated external environment. The test software is run through the industrial computer, and icons are dynamically reflected The current elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com