Flexibly-packaged lithium ion battery

A lithium-ion battery, flexible packaging technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as poor battery safety, affecting battery safety, and wrinkling of the pole ears, improving power performance and ensuring energy density. , the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]In the following, the present invention and its beneficial technical effects will be described in detail in accordance with the sequence of the production process in conjunction with the accompanying drawings and specific embodiments.

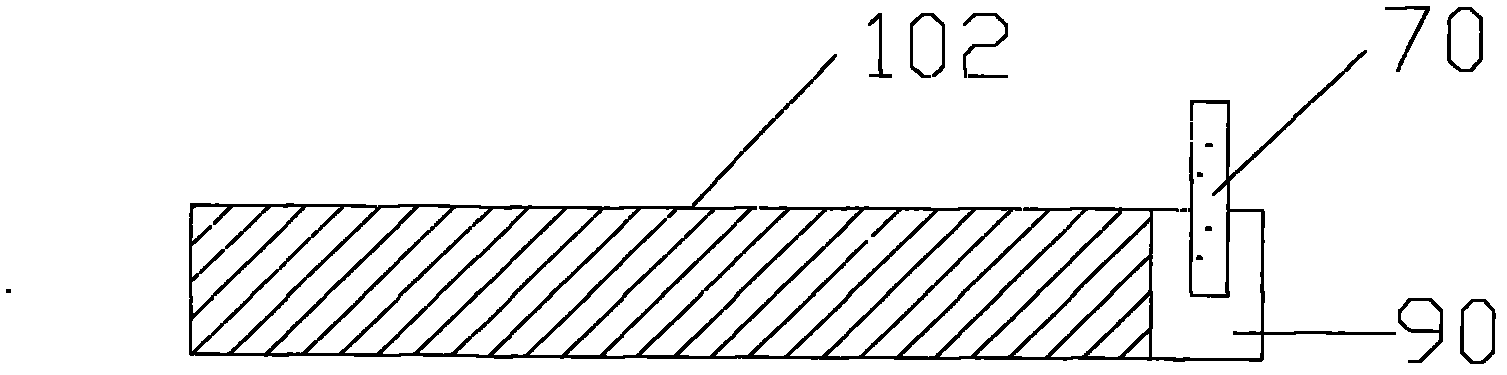

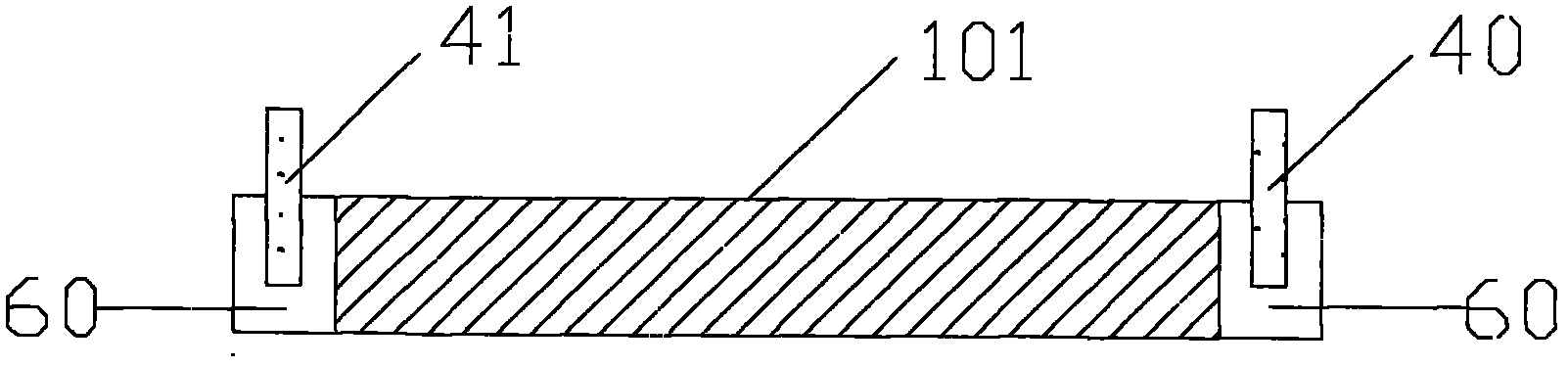

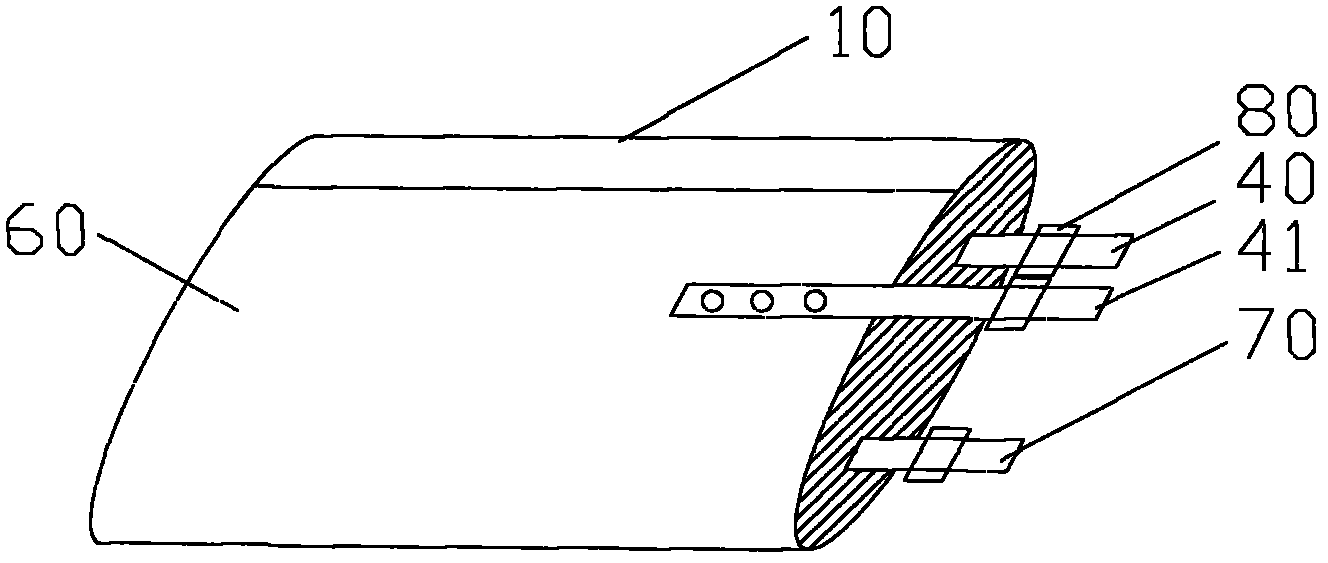

[0046] see Figure 1-5 , the present invention provides a flexible package lithium-ion battery, comprising a battery cell 10, a packaging bag 20 for containing the battery cell 10 and an electrolyte filled in the packaging bag 20, the battery cell 10 is composed of a positive electrode sheet 101. A negative electrode sheet 102 and a separator are wound. One end of the negative electrode sheet 102 is provided with a negative electrode tab 70, and the two ends of the positive electrode sheet 101 are respectively provided with a positive electrode inner tab 40 and a positive electrode outer tab 41. After winding, the positive inner tab 40 and the positive outer tab 41 are electrically connected through the tab transfer terminal 30 .

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com