Magnetic valve controllable reactor

A reactor and magnetic valve type technology, applied in the field of magnetic valve type controllable reactors, can solve the problems of increased installation workload, magnetic flux leakage, large fuel tank volume, etc., to avoid partial discharge, compact overall structure, and simplify the wiring process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

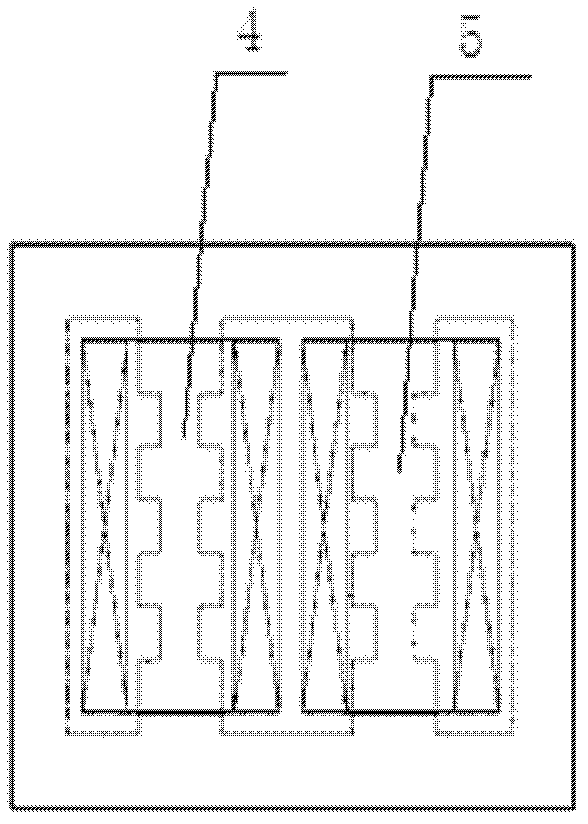

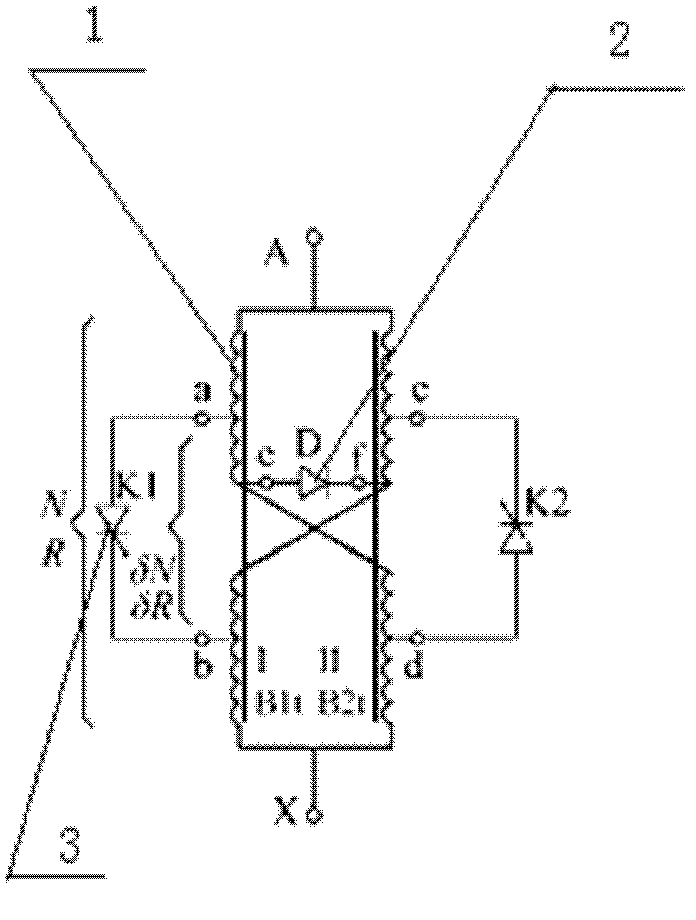

[0065] Figure 1A is a structural diagram of a single-phase MCR; Figure 1B is a schematic diagram of the principle of a single-phase MCR;

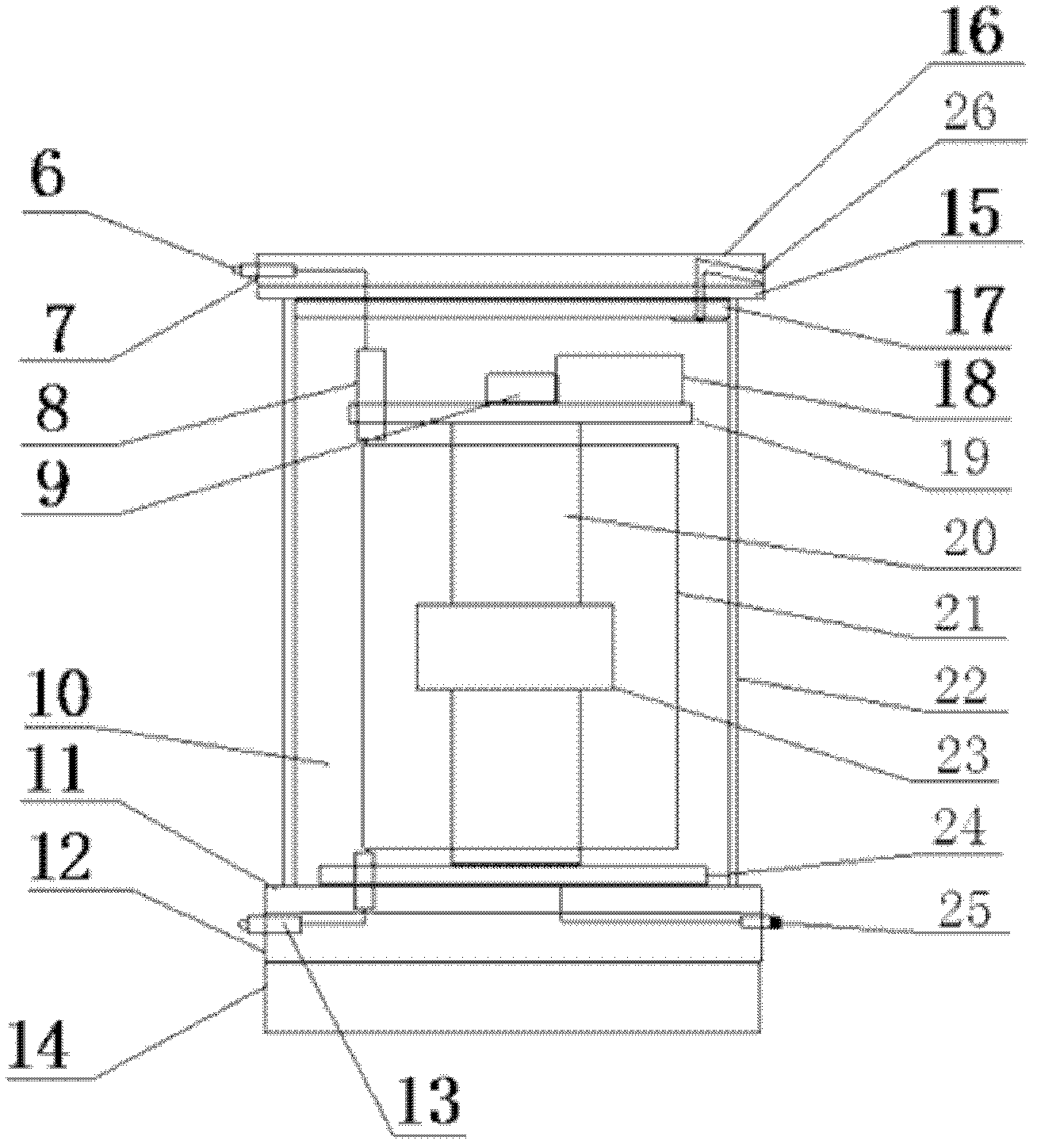

[0066] The magnetic valve type controllable reactor of the present invention has no side yoke structure, which constitutes a two iron core structure controllable reactor. The yoke constitutes a four-column iron core structure. The iron core structure of the present invention is a double iron core, and the side yokes on both sides are used at the top. There are only cross yokes connecting the two iron core columns, and there are double iron cores, as shown in Figures 1A and 1B. Coils are wound around each iron core column to form two main coils; at least one small section section is respectively arranged on the iron core column I 4 and II, and the upper and lower sides of the iron core column I 4 are respectively woun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com